A method for operating and managing valves in a power plant

A technology for operation management and power plants, applied in data processing applications, instruments, calculations, etc., can solve problems such as inability to accurately grasp valve status, difficulty in valve maintenance and management, and shortened valve life, so as to reduce the probability of misoperation and Space, large economy and convenience, and the effect of reducing the probability of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

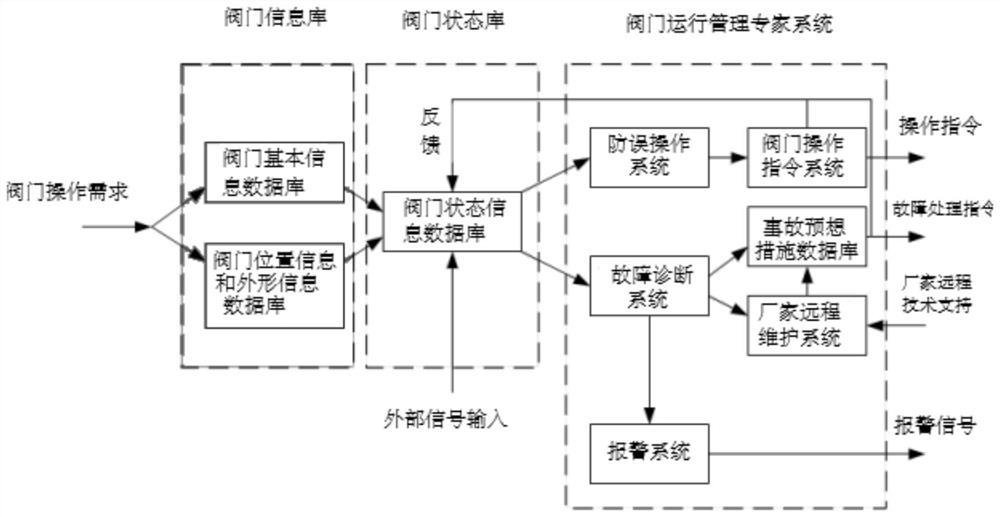

[0038] See figure 1 , the present invention provides a valve operation management method for the whole plant of a power plant, which is based on the valve operation management system to perform operation management of the valves of the whole plant of the power plant. The operation management system includes a valve information database, a valve status database and a valve operation management expert system, The valve information database includes a database of basic valve information and a database of valve position information and shape information, and the valve operation management expert system includes an error prevention operating system, an operation instruction system, a fault diagnosis system, an alarm system, and a database of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com