Multi-model Intelligent Optimization Predictive Control Method for Boiler Load under Low Load

A boiler load, predictive control technology, applied in control systems, adaptive control, general control systems, etc., can solve the problems of controlled process lag and inertia increase, difficult control, dynamic characteristics changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

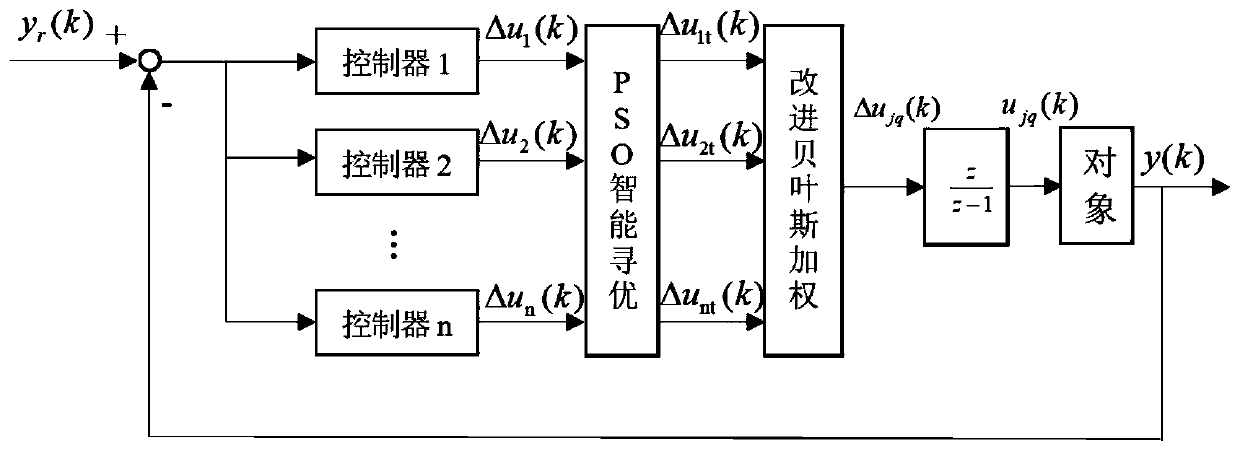

[0058] This implementation provides a multi-model intelligent optimization and predictive control method for boiler load under low load, including:

[0059] Step 1. Select a typical load point to establish a controlled object model. The method is to do a step response test at each load point to obtain the input and output data fitting to obtain the controlled object transfer function G(s).

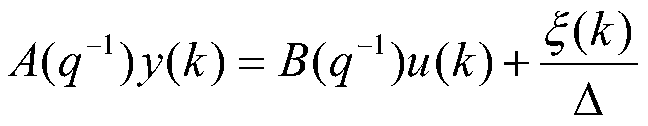

[0060] Step 2. Design the predictive controller according to the controlled object model at each load point, the method is as follows: according to the object transfer function, obtain the controllable autoregressive integral moving average (CARIMA) model,

[0061]

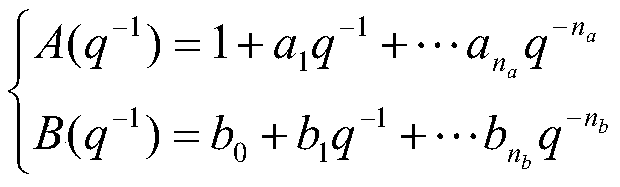

[0062] Among them, A(q -1 ), B(q -1 ) is the coefficient polynomial, ξ(k) is a random sequence, representing random noise, y(k) is the output sequence, u(k) is the input sequence, Δ=1-q -1 is a difference operator.

[0063]

[0064] By introducing the Diophantine equation,

[0065]

[0066] Among them, E(q -1 ), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com