Positioning device capable of fastening teaching instrument on vertical surface and using method of positioning device

A technology for positioning devices and facades, applied in the direction of fixing devices, connecting components, suction cups, etc., can solve problems such as difficult to remove, difficult to implement, and air leakage from suction cups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

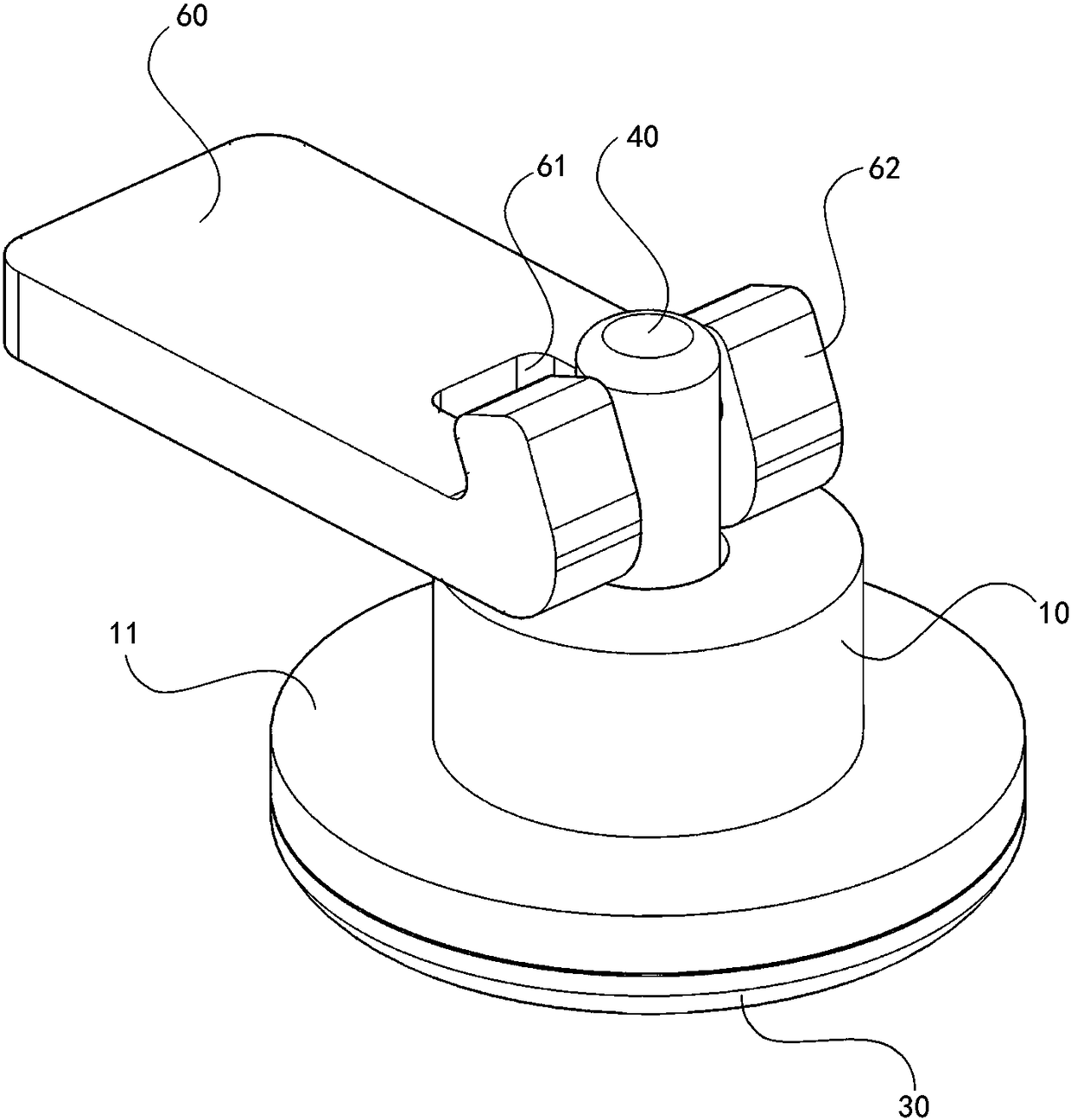

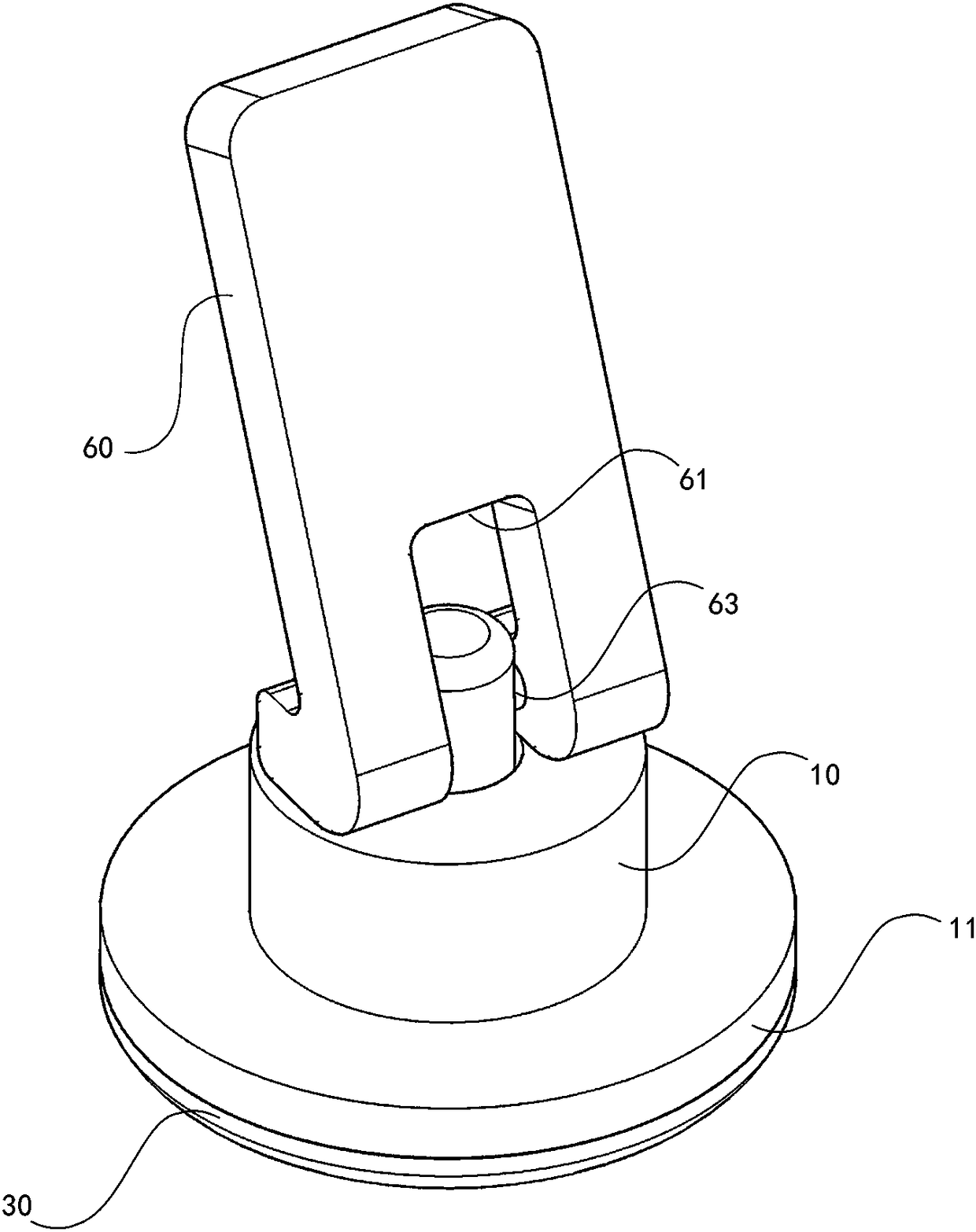

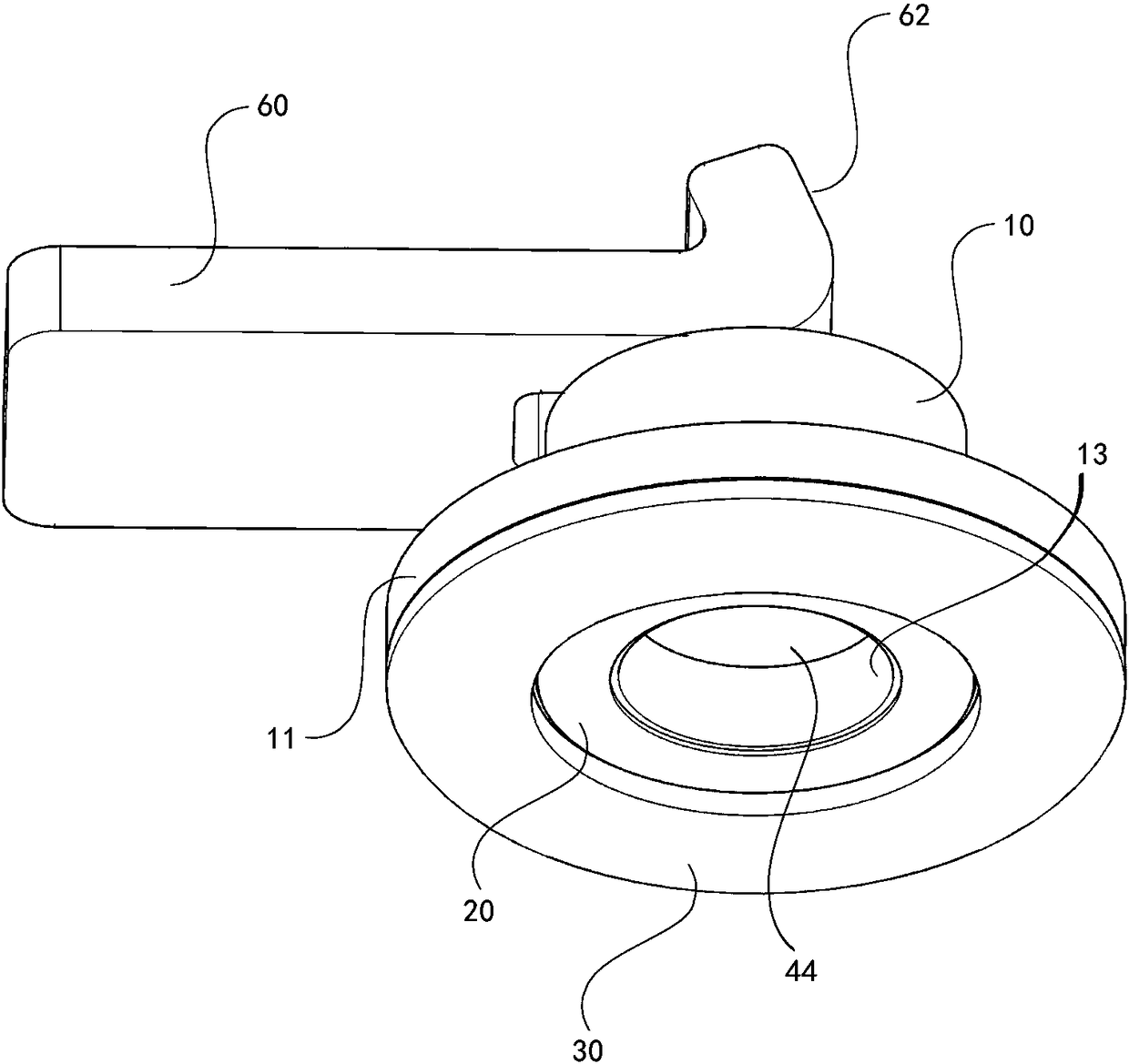

[0022] Below, the present invention will be further described in conjunction with accompanying drawing and embodiment: Figure 1 to Figure 4 Shown, a kind of positioning device that can fix teaching utensils on the vertical surface comprises positioner housing 10, anti-slip rubber ring 20, low-viscosity elastic rubber ring 30, pull rod 40, spring 50, wrench 60; It is characterized in that, described A pressure plate 11 is arranged below the locator housing 10, and a through hole 12 is arranged on the top, and the through hole 12 communicates with the inner cavity 13; The bottom surface 14 of the pressing plate is arranged on the outer ring of the convex ring 15; the anti-skid rubber ring 20 is fixed on the bottom surface of the convex ring 15; the low-viscosity elastic rubber ring 30 is fixed with the bottom surface 14 of the pressing plate; There is a shaft hole 41, the lower end is provided with a disc magnet 42; the middle of the disc magnet 42 is provided with a sealing ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com