Cement mortar tooth rake and method for laying tiles on floor

A technology of cement mortar and tooth rake, which is applied in the direction of construction and building construction, which can solve the problems of difficult quality assurance and low efficiency of laying floor tiles, and achieve the effect of improving the quality of laying and shortening the correction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

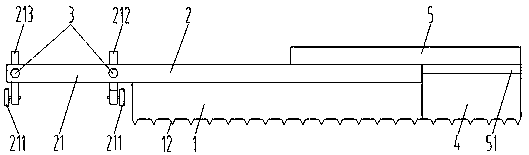

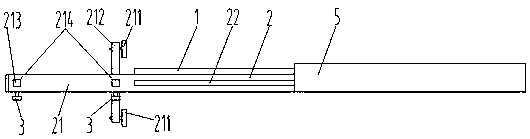

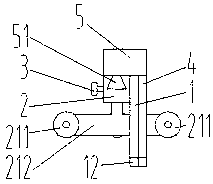

[0033] see figure 1 , cement mortar tooth rake, including rake body 1, said rake body 1 is a rectangular plate-shaped structure, its long side is horizontal and the plate surface is vertical to use its lower edge to scrape the cement mortar on the ground, the rake body 1 The lower edge is provided with several downward protruding teeth 12 equidistantly along its length direction to scrape out groove marks while scraping the cement mortar.

[0034] see figure 1 , image 3 , on one side of the rake body 1, a square strip 2 is connected along its upper edge for easy handling, and the square strip 2 extends out of one end of the rake body 1 and extends out of the square length The strip extension section 21 is formed as a holding and positioning part, and the lower surface of the square strip extension section 21 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com