An assembly workstation for a servo drive housing

A servo drive and workstation technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of irregular labor supply cycle, low work efficiency, hidden safety hazards, etc., to reduce labor costs and error rates, improve Productivity, the effect of avoiding dangerous problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the drawings and embodiments.

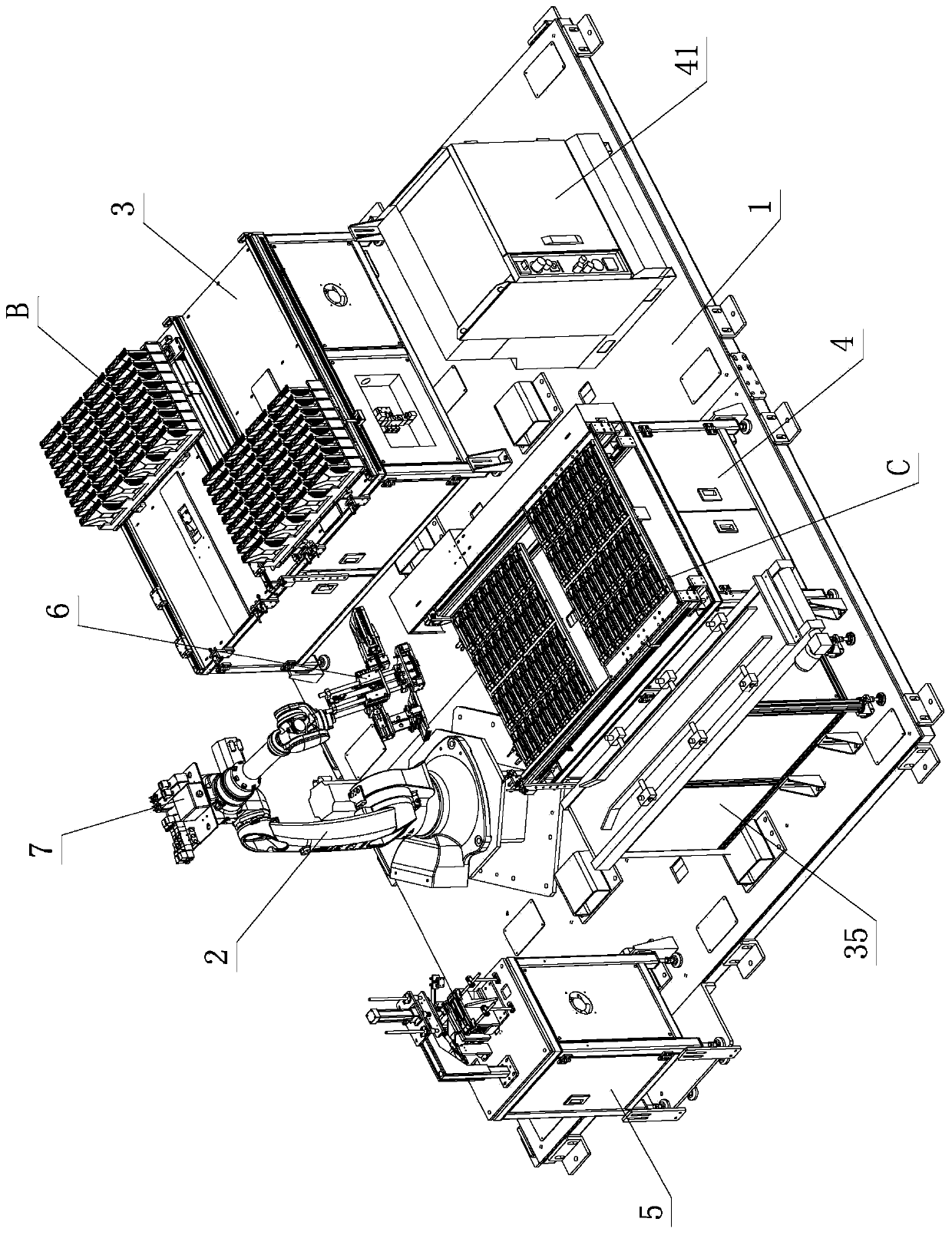

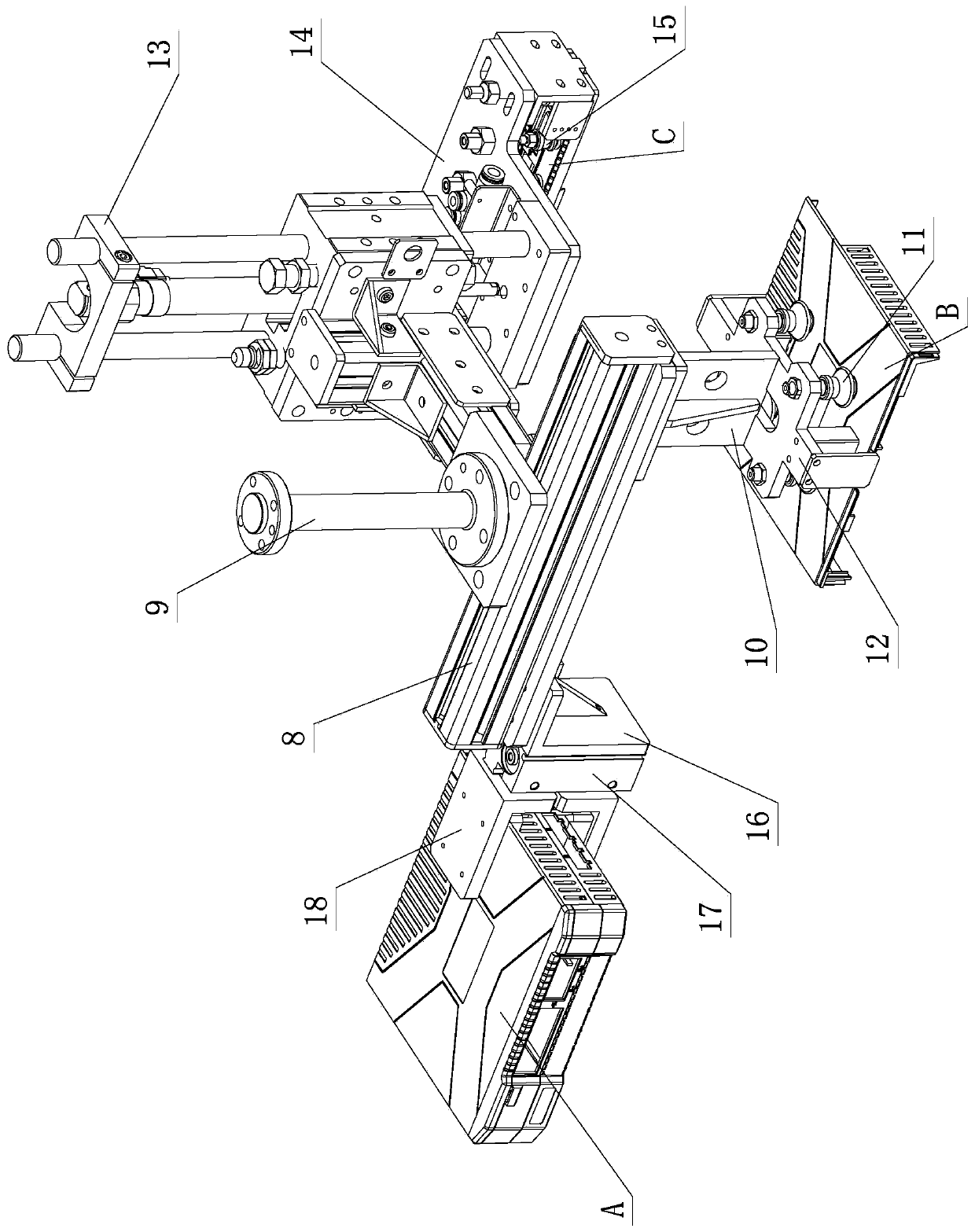

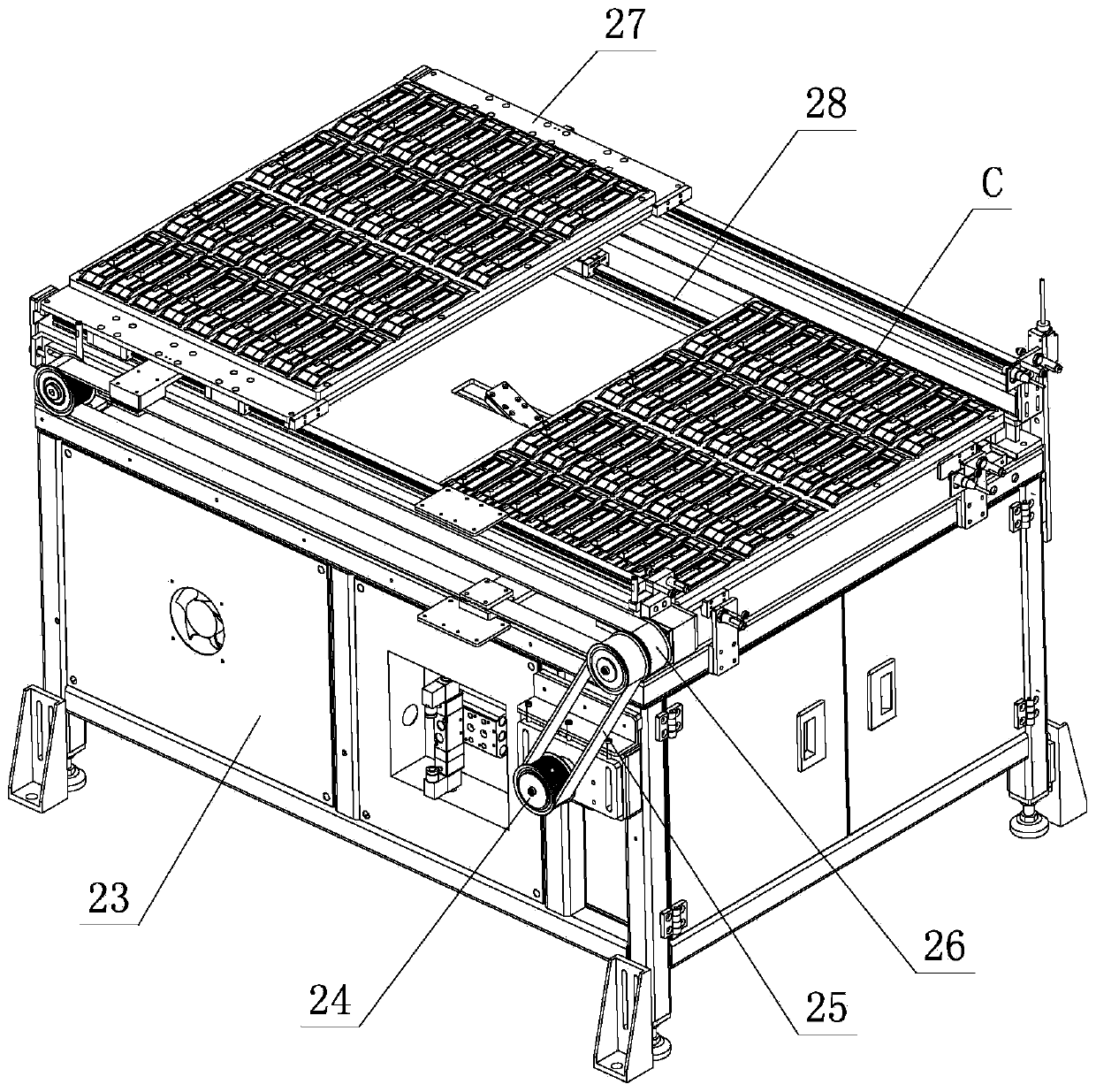

[0034] See Figure 1-Figure 9 , The assembly workstation of the servo drive housing includes a fixed base 1 and a servo drive assembly component. The servo drive assembly component includes at least a side housing B and an upper housing C. The fixed base 1 is equipped with a six-axis joint robot 2 and a side housing motor-driven Feeding table 3, upper shell motor-driven feeding table 4 and assembly press 5; among them, side shell B is placed on side shell motor-driven feeding table 3, and upper shell C is placed on upper shell motor-driven On the loading table 4; the six-axis joint robot 2 is provided with a loading and unloading fixture 6, the six-axis joint robot 2 through the loading and unloading fixture 6 respectively from the side shell motor-driven loading table 3, the upper shell motor drive The side shell B and the upper shell C are clamped on the material tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com