Method for preparing frozen dough and articles prepared using the method

A technology of freezing dough and dough, which is applied in the direction of dough preparation, dough processing, and dough ready for oven, etc. It can solve the problems of difficult production of products, and achieve the goals of saving cooking time, avoiding freshness, and ensuring quality and taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] The present invention provides frozen dough products and methods for their preparation. In particular, the present invention provides methods of producing bread, steamed bread, fried bread and microwave bread frozen dough products that are raw and can be cooked directly from the frozen state to produce a finished product for consumption. According to an embodiment of the present invention, the preparation method comprises the steps of subjecting the frozen dough product to at least one freeze-thaw cycle, then refreezing the dough, and storing the dough product under frozen conditions.

[0048] The terms "freeze-thaw cycle" or "freeze-thaw cycle treatment" are used herein to refer to the treatment of dough, which is defined as subjecting the dough to at least one change in the ice-water phase transition in the dough, from a frozen state, to thawing, and then to recovery to a completely frozen state. The term "freeze-thaw cycle" as used herein refers to the process of pe...

Embodiment 1

[0061] According to an embodiment of the present invention, frozen dough products were prepared from dough recipes and preparation methods, and the quality of dough balls were compared.

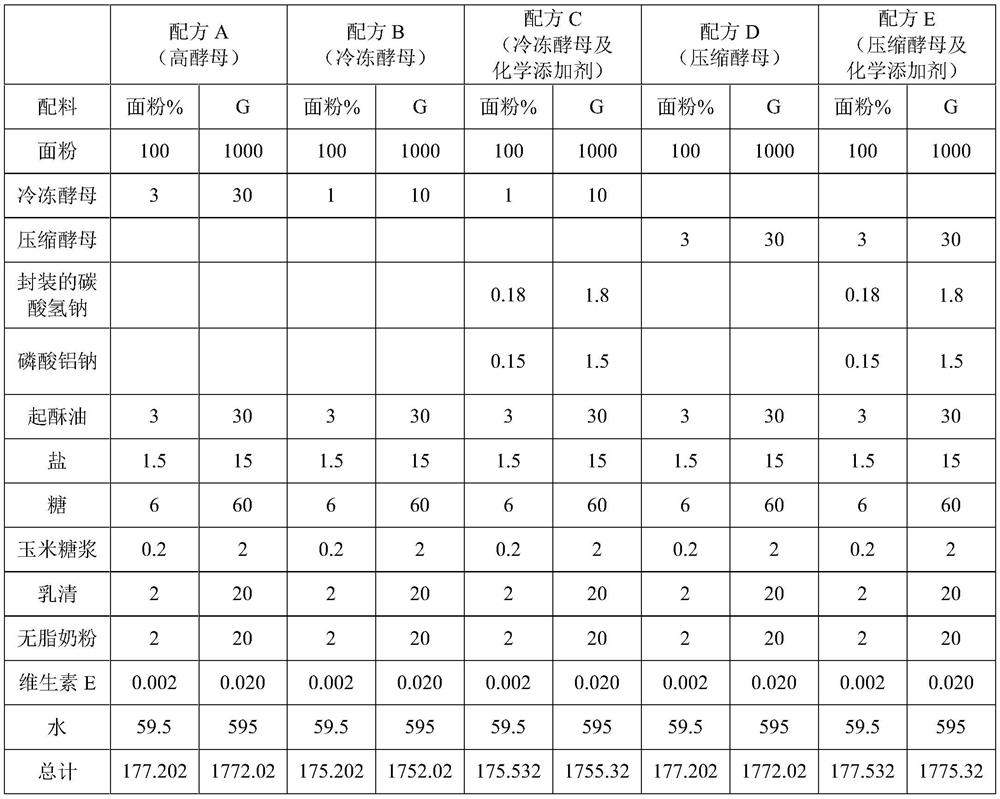

[0062] Sample Preparation: Dough formulations of approximately 1700 g each were prepared according to Table 1 using a stand mixer. Add flour and dry ingredients and mix for 1 minute before adding yeast and water. The contents were mixed for 2 minutes on low speed and 4 minutes on high speed. Divide the dough into 100g dough pieces and roll the dough pieces by hand into dough balls. The specific volume of the dough is about 1.3-1.5 ml / g. The prepared dough balls were frozen to -29°C and stored at -29°C until treatment was applied.

[0063] Processing: All samples except those tested were transferred from the -29°C freezer to the -18°C freezer on day 3 and kept in the -18°C freezer until use. Test samples were processed with freeze-thaw cycles. During freeze-thaw cycle processing, test sam...

Embodiment 2

[0068] Dough recipes were prepared according to embodiments of the present invention, and the quality of the product was evaluated after baking. The frozen dough of Example 1 was stored at -18°C for 2 weeks and then used for baking tests and evaluation of baking quality.

[0069] Processing: Samples stored in the freezer for the negative reference were transferred directly to the oven for baking without any pre-baking treatment. At the same time a positive reference is prepared. When handling the positive reference the dough balls were thawed in a covered container at room temperature for 2 hours, then the dough was proofed at 35°C and 75% humidity for 30 minutes before being baked immediately. Thus, the positive reference was fermented and rested before roasting, while the negative reference was left untreated before roasting. The test samples of the present invention were samples that had been subjected to the freeze-thaw cycles from Example 1 and were not fermented or res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com