Valve assembly for injection valve, injection valve and method of assembling injection valve

A technology of valve components and injection valves, which is applied in the direction of fuel injection devices, special fuel injection devices, charging systems, etc., can solve the problems of increasing the length of the injector, and achieve the effect of reducing the overall length and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

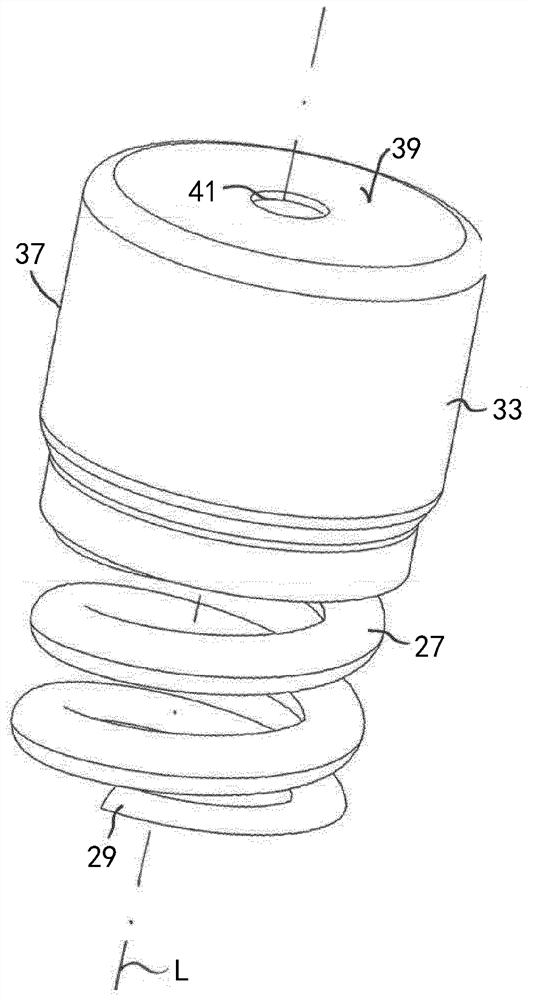

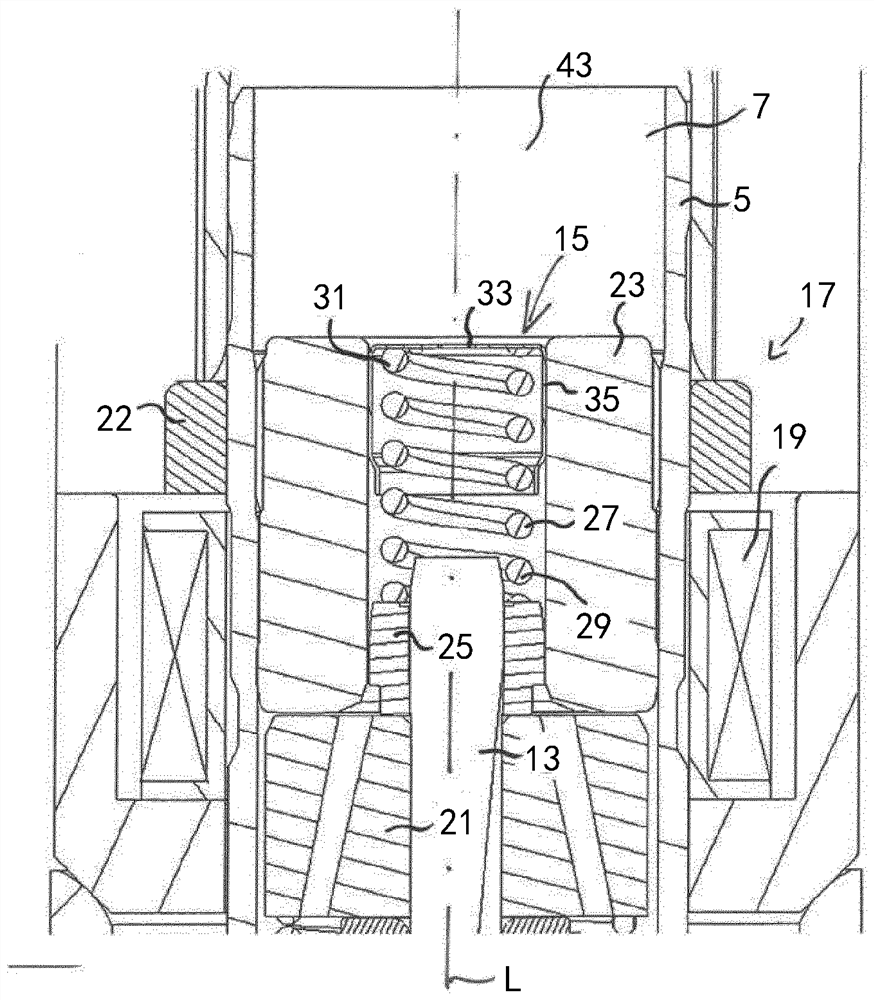

[0031] Elements of the same design and function that appear in different figures are designated with the same reference numerals.

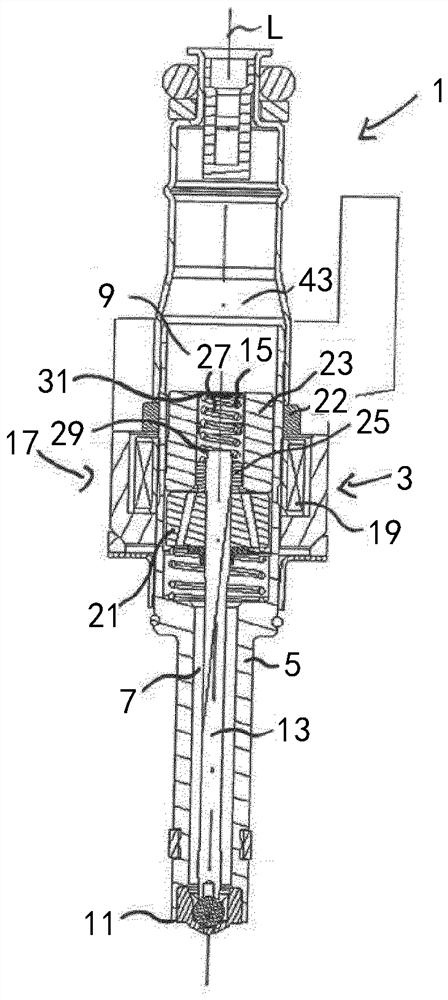

[0032] figure 1 A fluid injection valve 1 according to an exemplary embodiment is shown in a schematic longitudinal section. figure 1 The details are in figure 2 Shown enlarged.

[0033] exist figure 1 and figure 2 The fluid injection valve 1 shown in is particularly suitable for metering fuel in internal combustion engines. However, the invention can also be used in other types of injection valves.

[0034] Injection valve 1 includes a valve assembly 3 . The valve assembly 3 comprises a valve body 5 having a central longitudinal axis L. As shown in FIG. The valve body 5 includes a cavity 7 . The chamber 7 has a fluid outlet portion 11 . The fluid outlet portion 11 is in hydraulic communication with the fluid inlet portion 9 of the chamber 7 via the chamber 7 . In particular, the fluid inlet portion 9 and the fluid outlet portion 11 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com