Full-automatic glue dispersion assembly line of motor shell

A motor housing, fully automatic technology, applied in electric components, manufacturing motor generators, electromechanical devices, etc., can solve the problems of inability to apply glue to a fixed position, uneven amount of glue, low work efficiency, etc., to achieve automation The effect of uniform and reliable dispensing volume, reducing labor costs and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

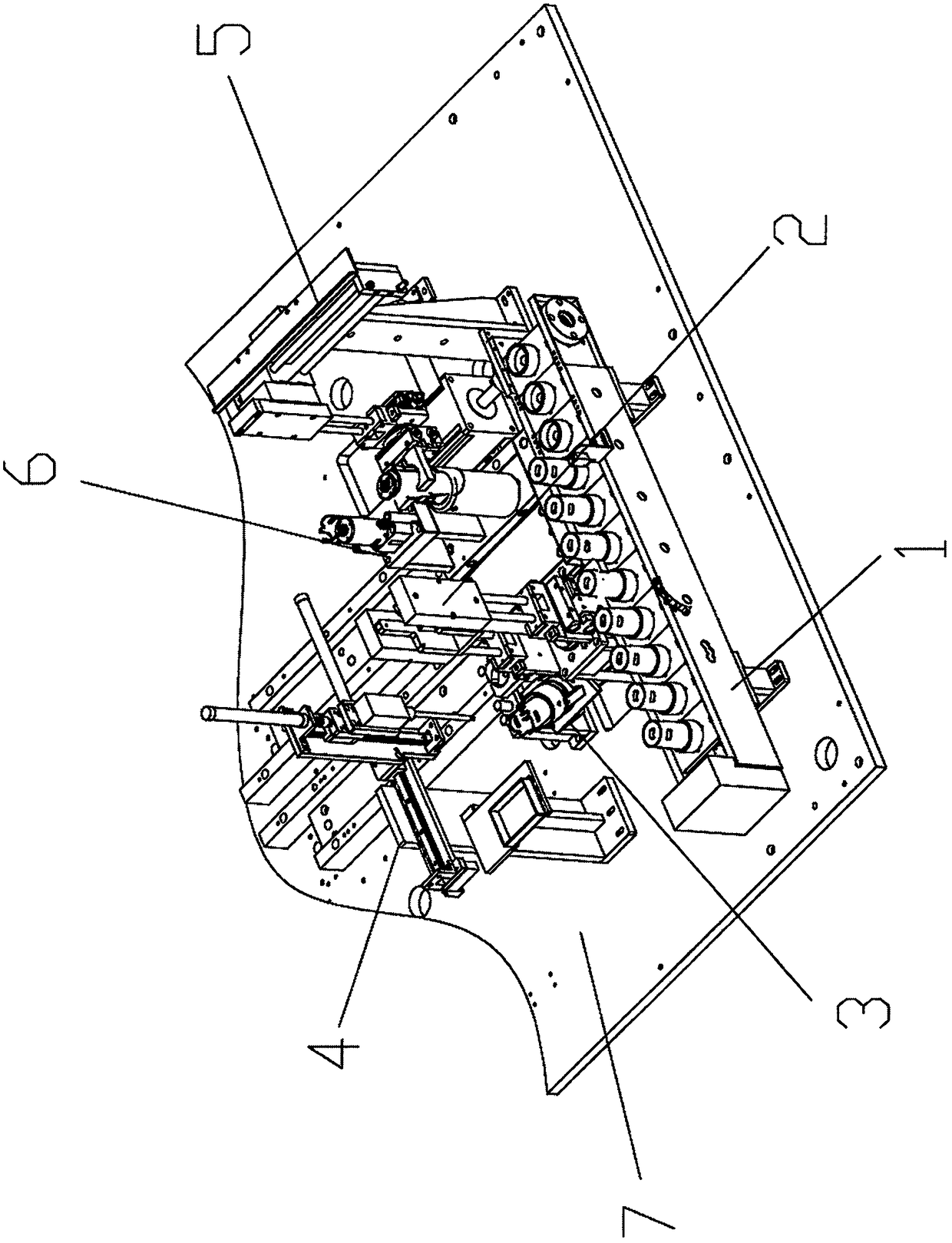

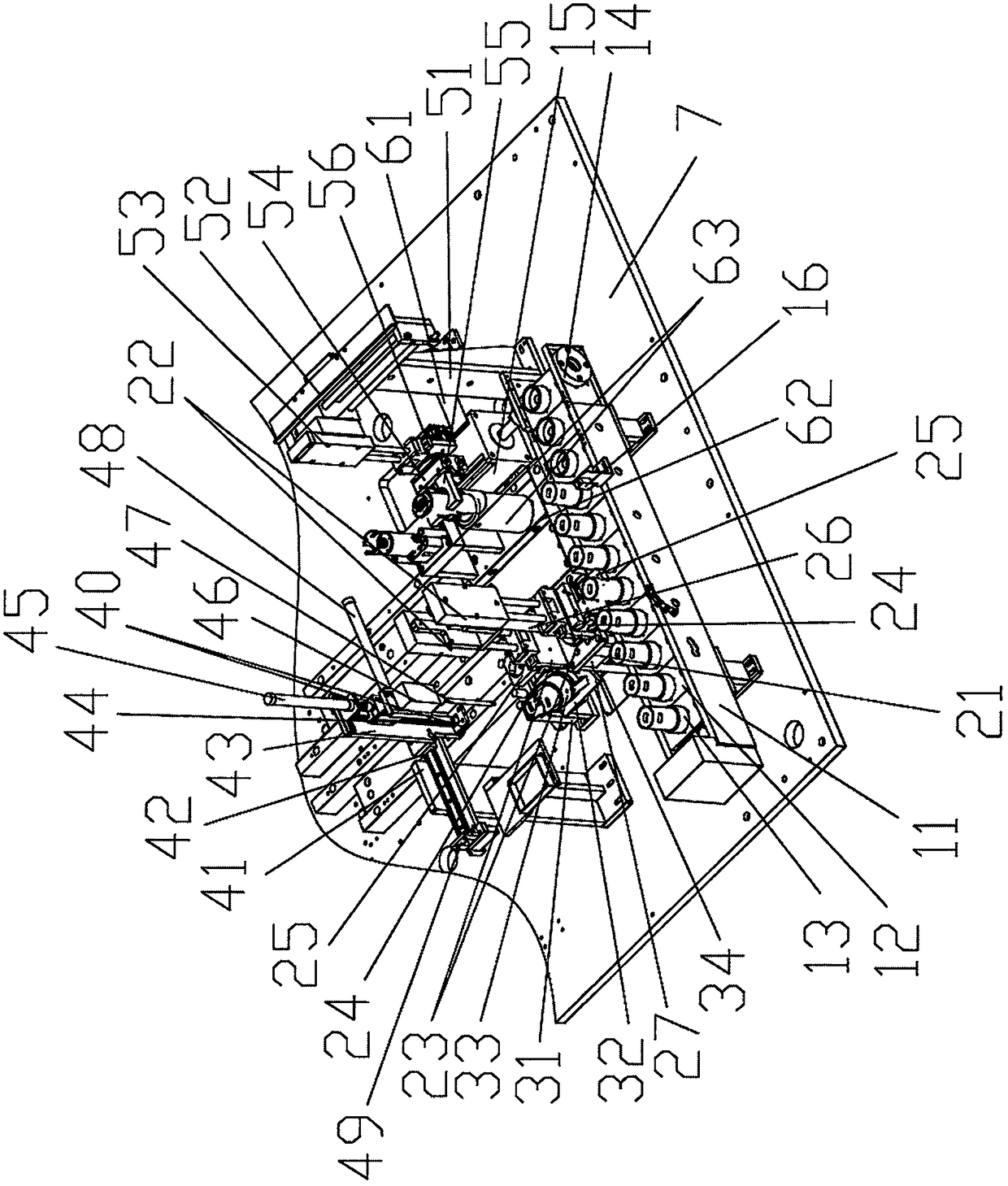

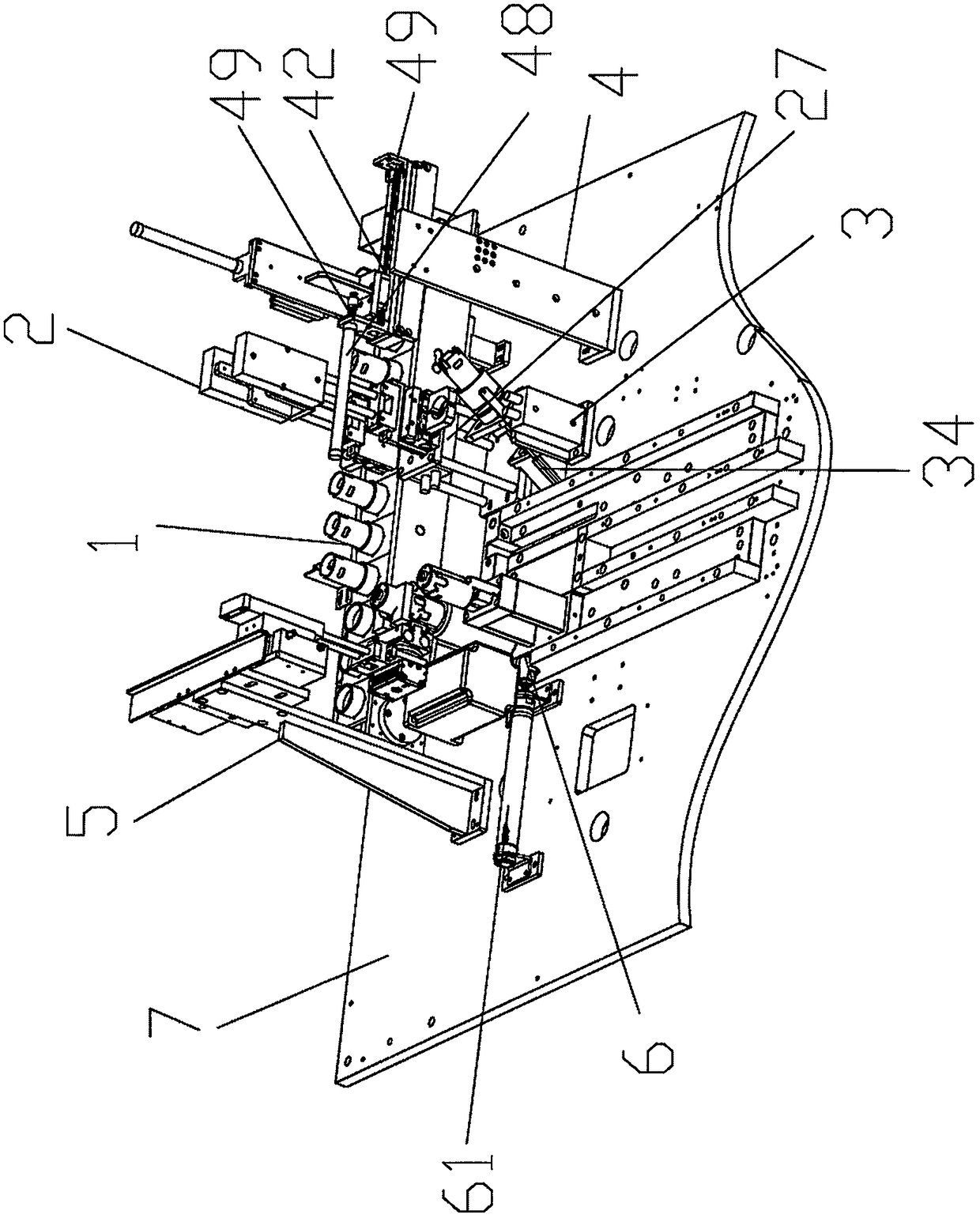

[0024] Such as Figure 1-Figure 9 As shown, a fully automatic glue dispensing line for motor shells described in this embodiment includes a transmission mechanism 1, a positioning and picking manipulator 2, a rotating mechanism 3, a glue dispensing mechanism 4, a flipping and picking manipulator 5, a mobile Loading mechanism clamp 6, total air valve, PLC controller and frame 7.

[0025] Transmission mechanism 1: After placing the undispensed motor housing and the dispensed motor housing in a vertical position with the opening facing upwards, transfer the undispensed motor housing to the position adjustment and pick-up manipulator in the middle , to synchronously transmit the dispensed motor housing to the flip-picking manipulator at the front end; And be used for positioning seat one 13 of positioning motor housing and two synchronous belt pulleys 14, two synchronous belt pulleys 14 are respectively fixed on the two ends of support one 11, servo motor 15 is fixed with a synch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com