Roller body lifting and adjusting carrying mechanism for fabric processing

A technology of lifting adjustment and handling mechanism, which is applied in the direction of conveyor objects, transportation and packaging, lighting and heating equipment, etc. It can solve the problems of large manual labor, unsatisfactory effect, low efficiency, etc., and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

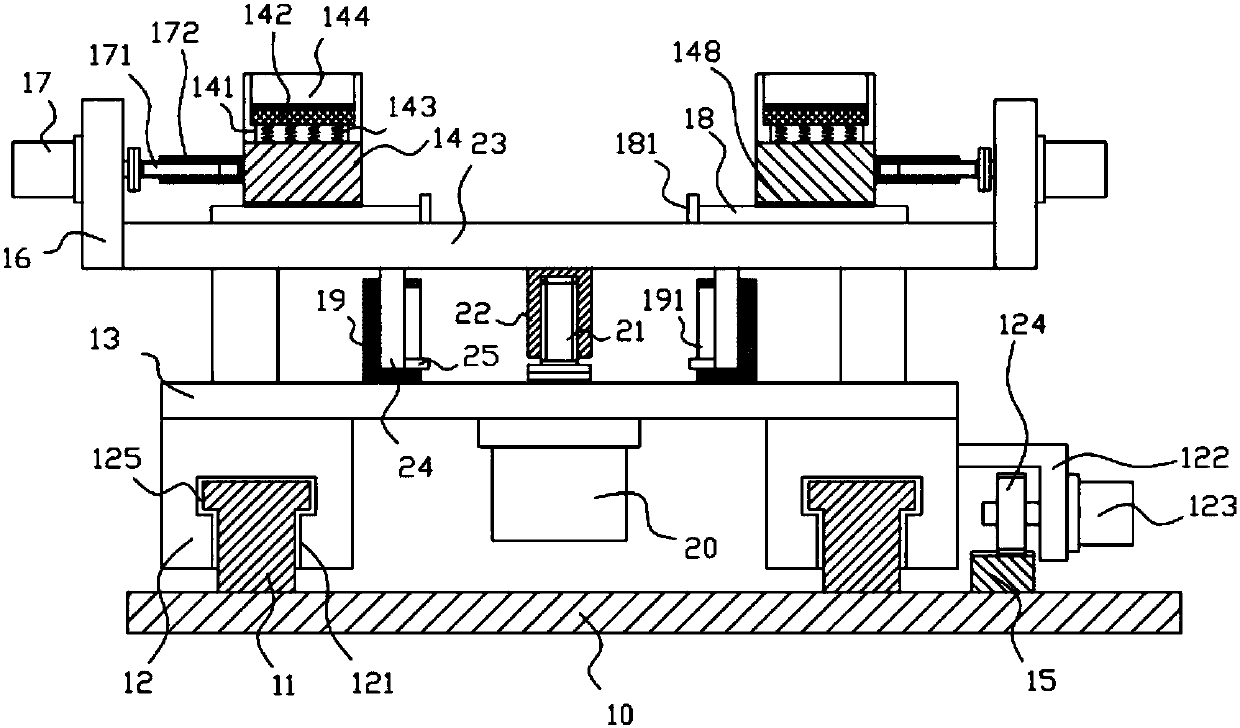

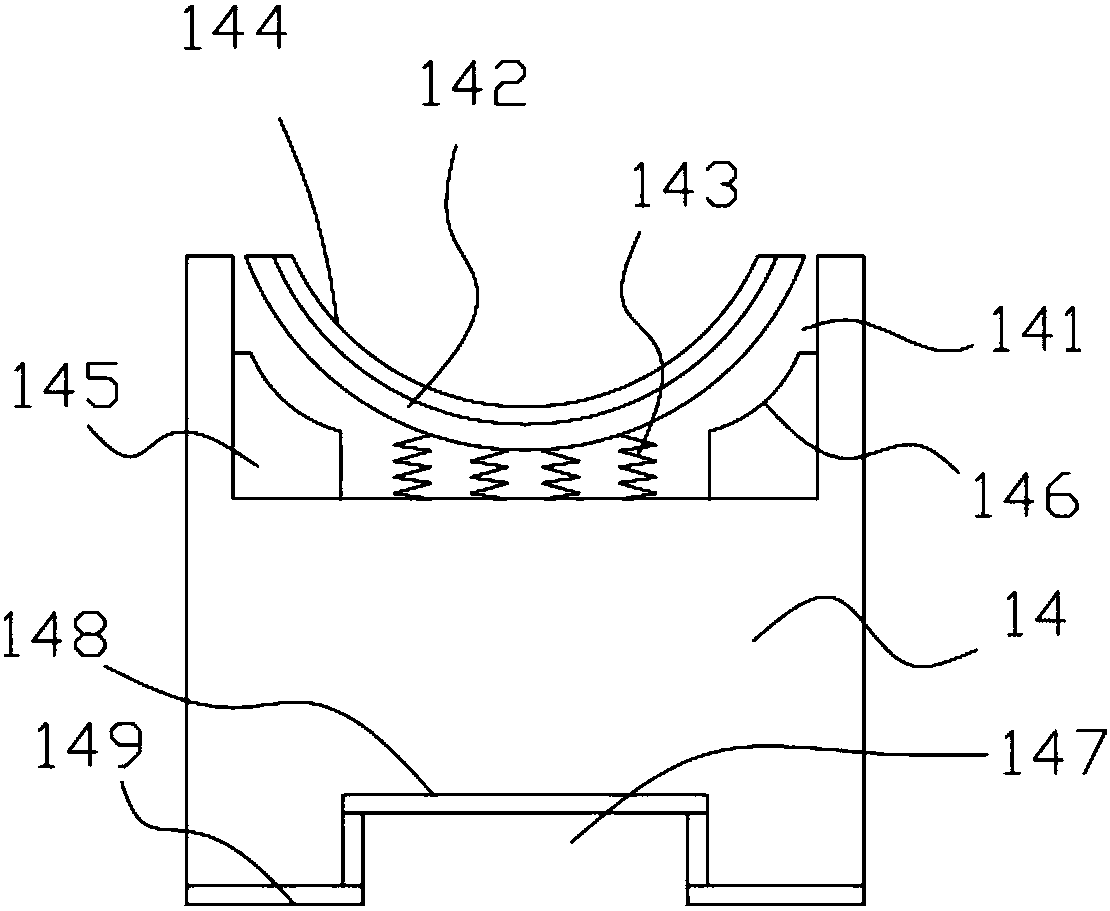

[0021] Example: see Figure 1 to Figure 2 As shown, a roller body lifting adjustment transport mechanism for fabric processing includes a bottom plate 10, the top surface of the left side and the right side of the bottom plate 10 is fixed with a conveying guide rail 11, and the conveying guide rail 11 is inserted and sleeved on the bottom surface of the moving block 12. The horizontal plate 13 is fixed on the top surface of the two moving blocks 12 in the guide channel 121, the middle part of the bottom surface of the horizontal plate 13 is fixed with a lifting motor 20, and the output shaft of the lifting motor 20 passes through the horizontal plate 13 and passes through the coupling Be connected with vertical screw rod 21, vertical screw rod 21 is screwed in the lifting screw sleeve 22, the top of lifting screw sleeve 22 is fixed with lifting plate 23, is fixed with side support plate 16 on the left and right side walls of lifting plate 23, side support An adjusting motor 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com