Casting anti-oxidation device and method

A technology for anti-oxidation and castings, which is applied in the direction of casting equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of decarburization of castings, deterioration of casting surface quality and service life, etc., so as to improve service life, good anti-oxidation effect, improve The effect of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

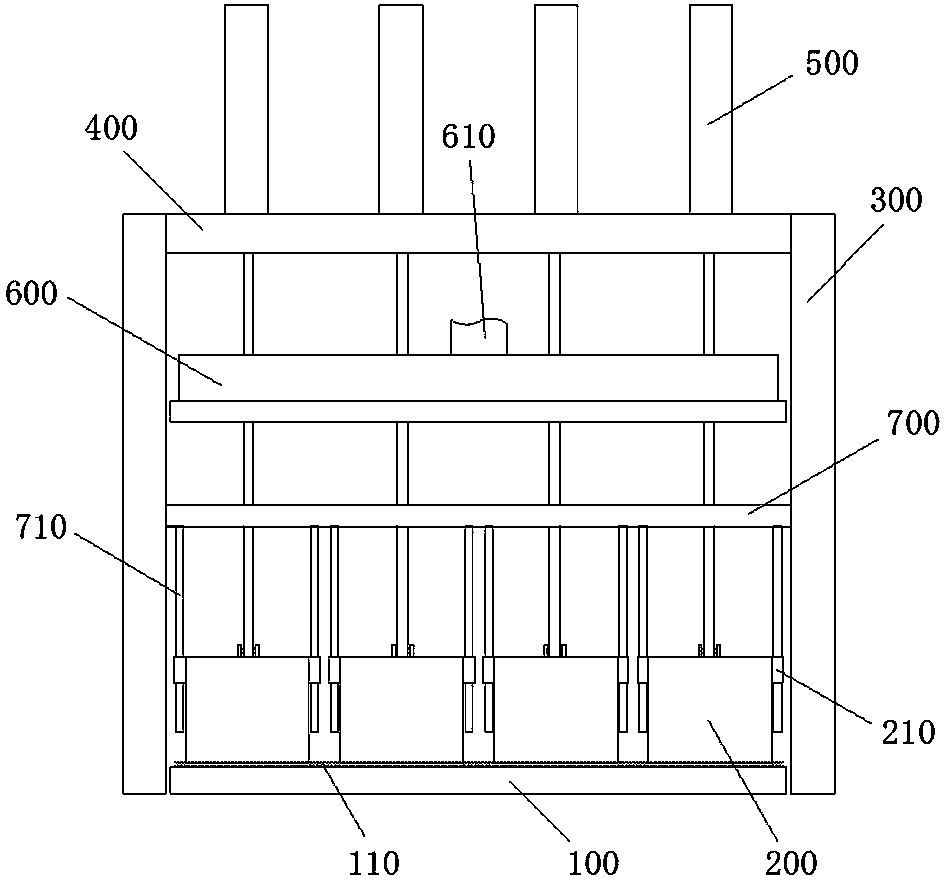

[0013] Such as figure 1 As shown, a casting anti-oxidation device includes a sand tank 100 located at the bottom and filled with sand 110. Above the sand tank 100, there are a plurality of covers 200 that are buckled on the sand and can be lifted up. Lift up the cover, put the cast casting on the sand directly under the cover, then put a burning wax block on the casting, use the temperature of the casting to ignite the burning wax block, then cover the cover, use the burning wax block The combustion exhausts the oxygen in the cover, so that the castings are cooled in an oxygen-free environment, avoiding the oxidation of the casting surface, the anti-oxidation effect is good, the surface quality of the castings is improved, and the service life of the castings is increased.

[0014] In this embodiment, all the covers 200 are arranged in a line along the length direction of the sand tank 100. There are brackets 300 erected at both ends of the sand tank 100, and a first crossbeam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com