Burdening equipment

A batching equipment and batching box technology, applied in the field of machinery, can solve the problems of long waiting time and slow batching speed, and achieve the effect of less time, fast batching and good extrusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

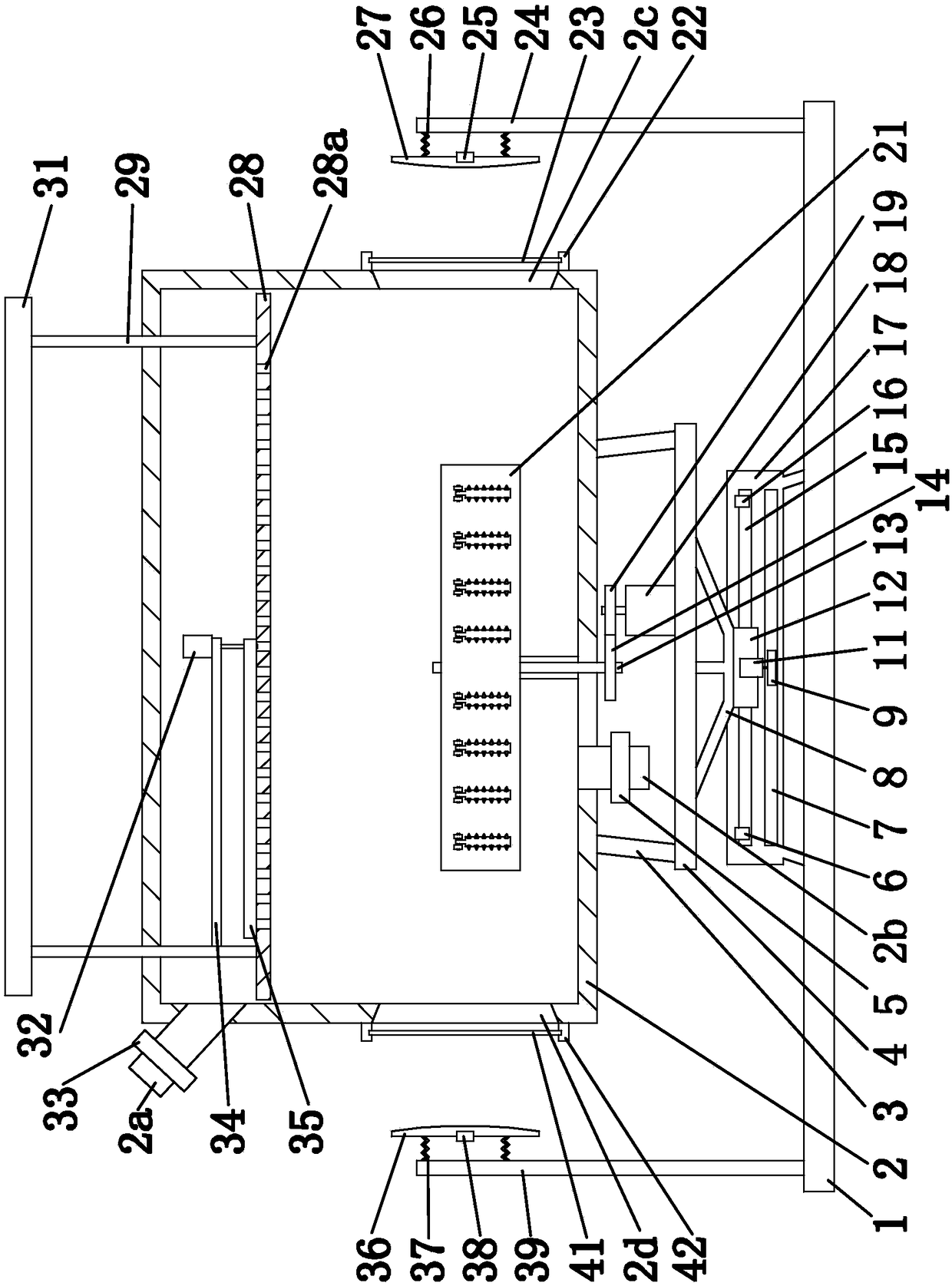

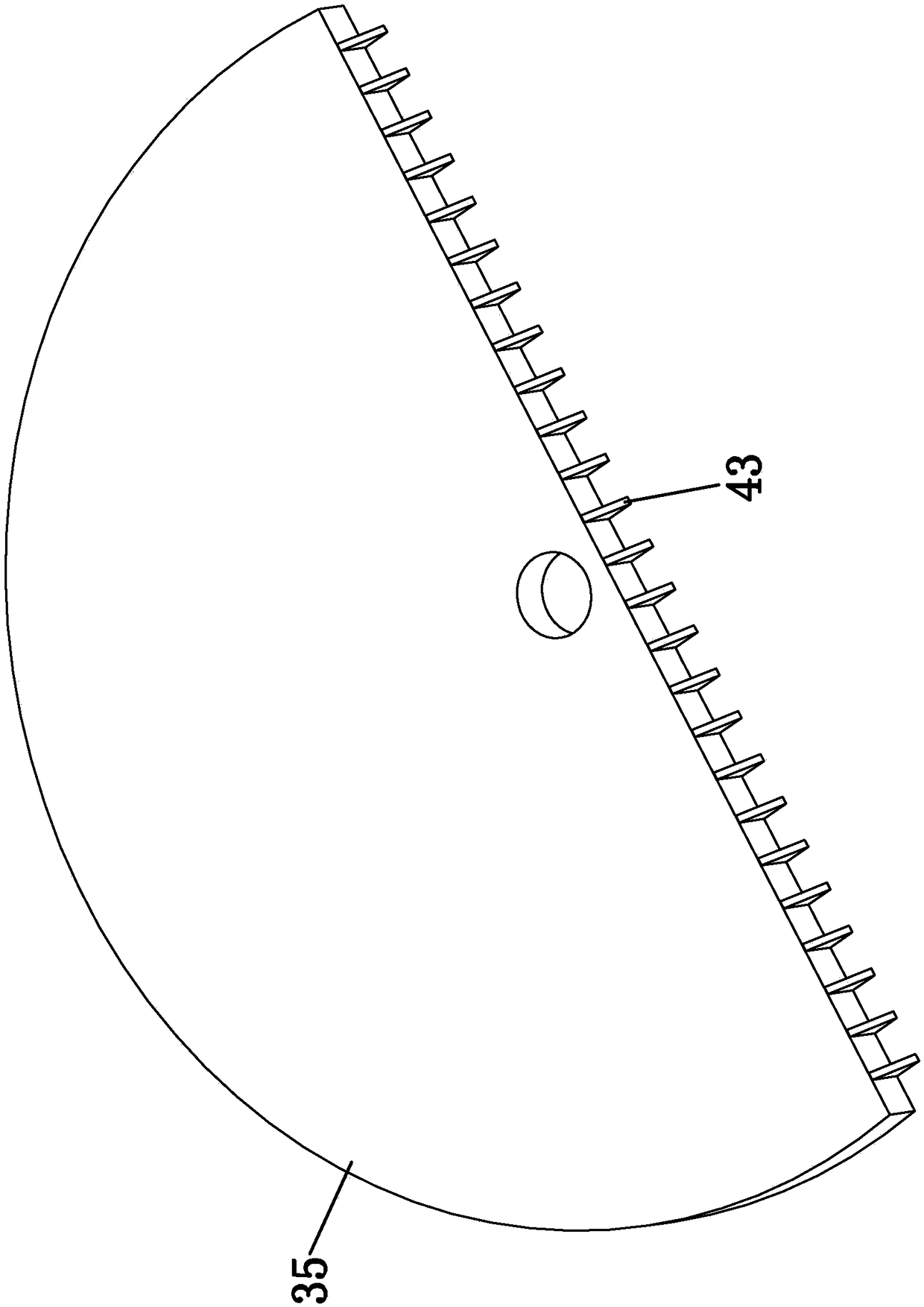

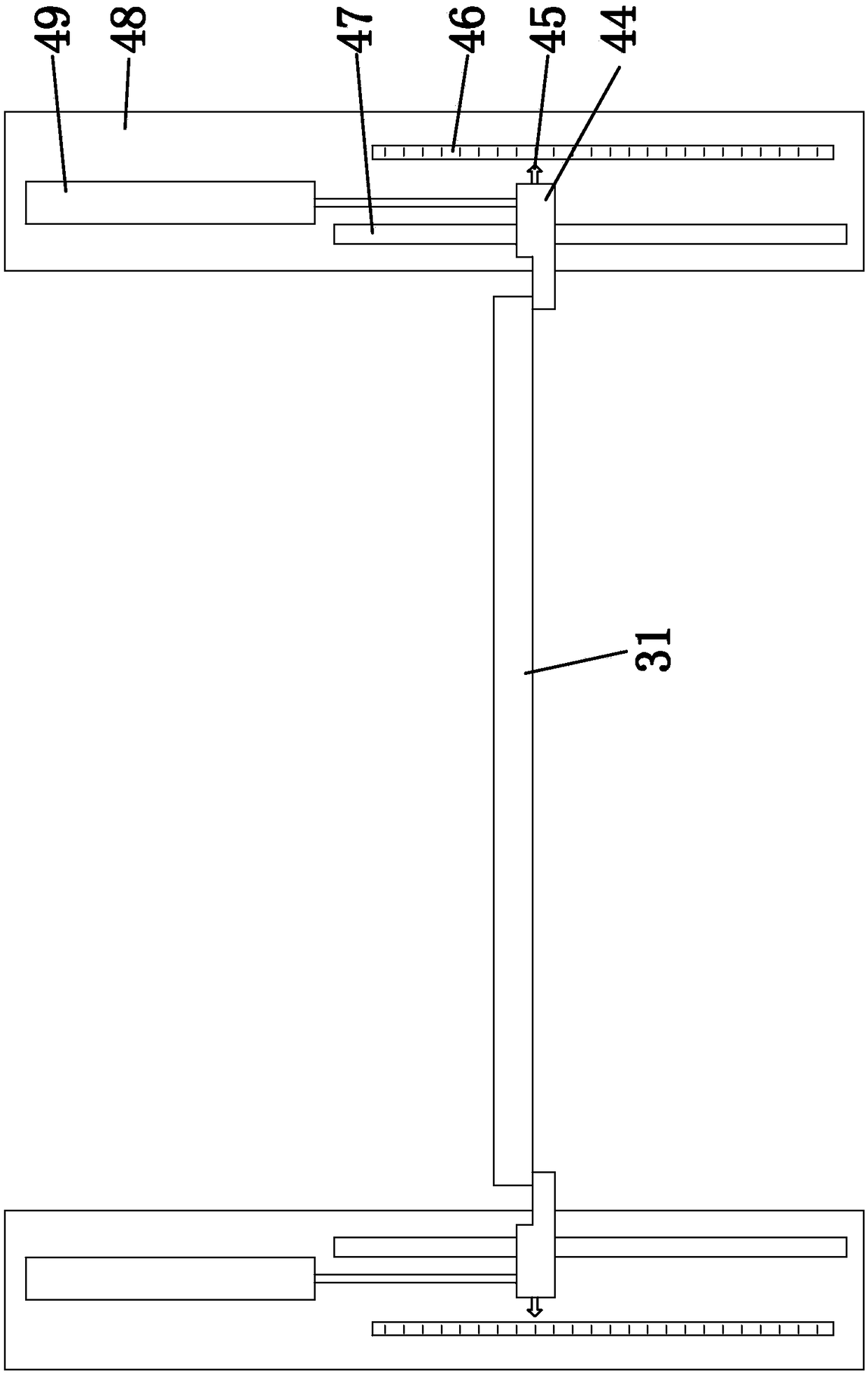

[0044] like Figure 1-Figure 4 As shown, the batching equipment includes a base 1. A moving seat 4 is arranged on the base 1. The moving seat 4 is connected to a mobile structure that can drive it to move back and forth. The upper part of the box 2 has a feeding port 2a, the feeding port 2a is provided with a solenoid valve 1 33, the lower part of the batching box 2 has a discharge port 2b, the discharge port 2b is provided with a solenoid valve 2 5, and the bottom of the batching box 2 is provided with a stirring shaft 13 , and the stirring shaft 13 is arranged vertically, the lower end of the stirring shaft 13 stretches out from the batching box 2 and is connected with a drive structure that can drive it to rotate, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com