Auxiliary tripping pipe equipment and operation method suitable for remedial work with pressure

An equipment and operation technology, applied in drilling equipment, drill pipe, casing and other directions, can solve problems such as hidden safety hazards and low operation efficiency, achieve the effect of compact structure, improve the degree of automation, and eliminate the problem of idle travel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation of the present invention will be illustrated below in conjunction with the accompanying drawings, but it should not be understood that the scope of the above-mentioned subject of the present invention is limited to the following examples, and all technologies realized based on the contents of the present invention belong to the scope of the present invention.

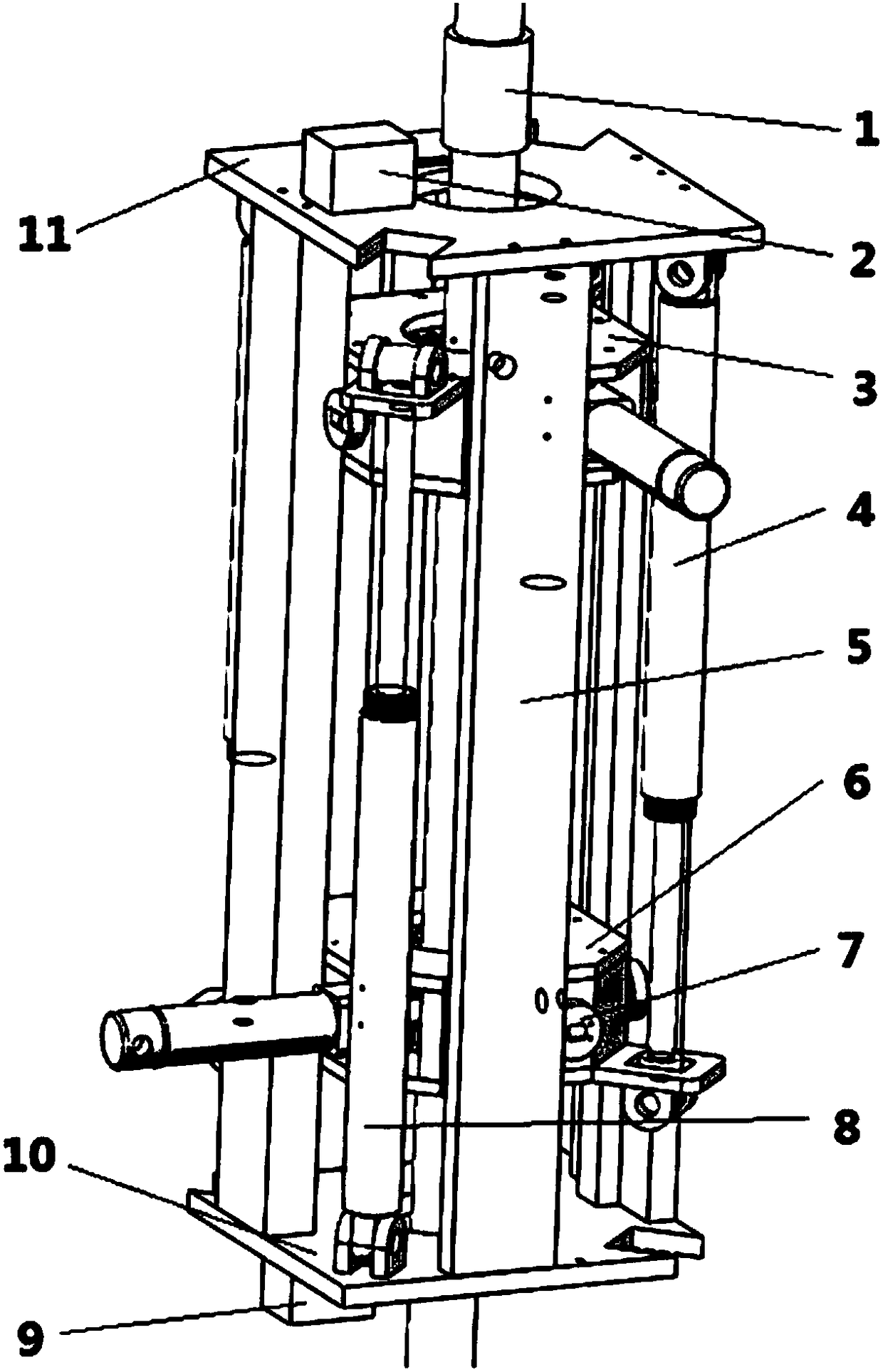

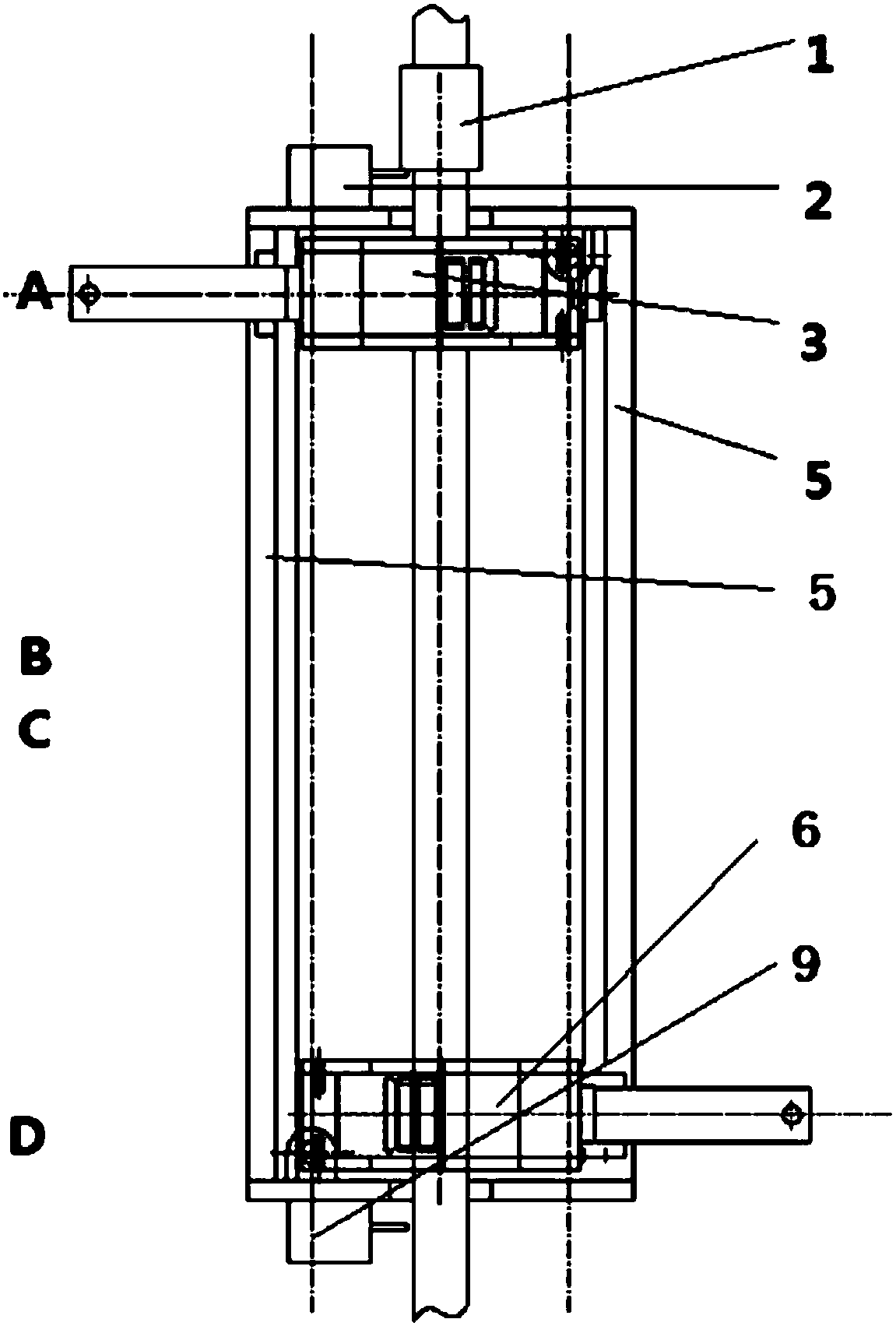

[0039] An auxiliary pipe tripping device suitable for workover operations under pressure. The auxiliary tripping pipe device is installed on the blowout blowout group under pressure through the wellhead installation flange, including oil pipe 1, upper and lower pipe string collar detectors 2, 9. Upper and lower end plates 11, 10, upper and lower pipe string clamping devices 3, 6, upper and lower pipe string oil cylinders 4, 8, lifting mechanism 7, support column 5.

[0040] The upper and lower end plates 11 and 10 have the same structure and are square plates with a through hole in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com