Early-warning method for gear case bearing fault of wind turbine generator system

A fault warning and wind turbine technology, applied in mechanical bearing testing, etc., can solve problems such as poor timeliness, high hoisting and maintenance costs, and aggravated economic losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0067] The present invention provides a wind turbine gearbox bearing failure early warning method, the method comprising the following steps:

[0068] Step 1: collection of SCADA operation data;

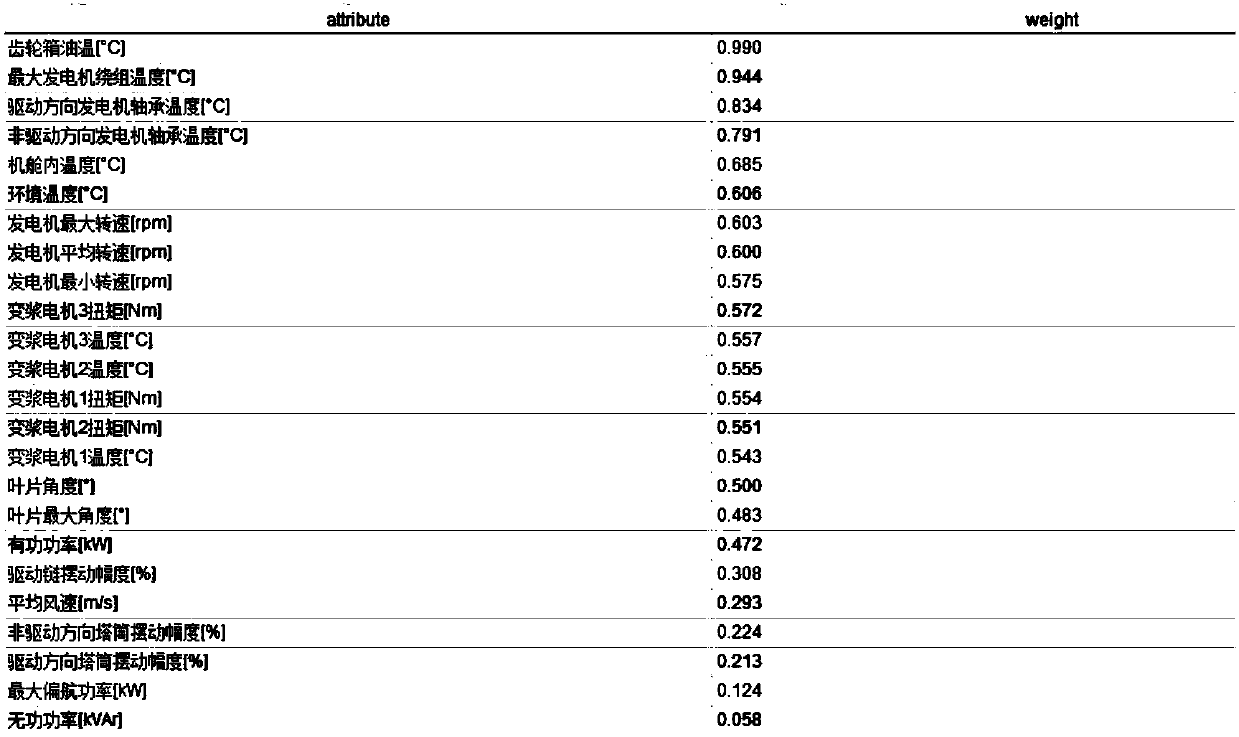

[0069] Step 2: parameter selection;

[0070] Step 3: parameter correlation analysis;

[0071] Step 4: Determine the target variable and analysis variable, and perform interval analysis of the target variable;

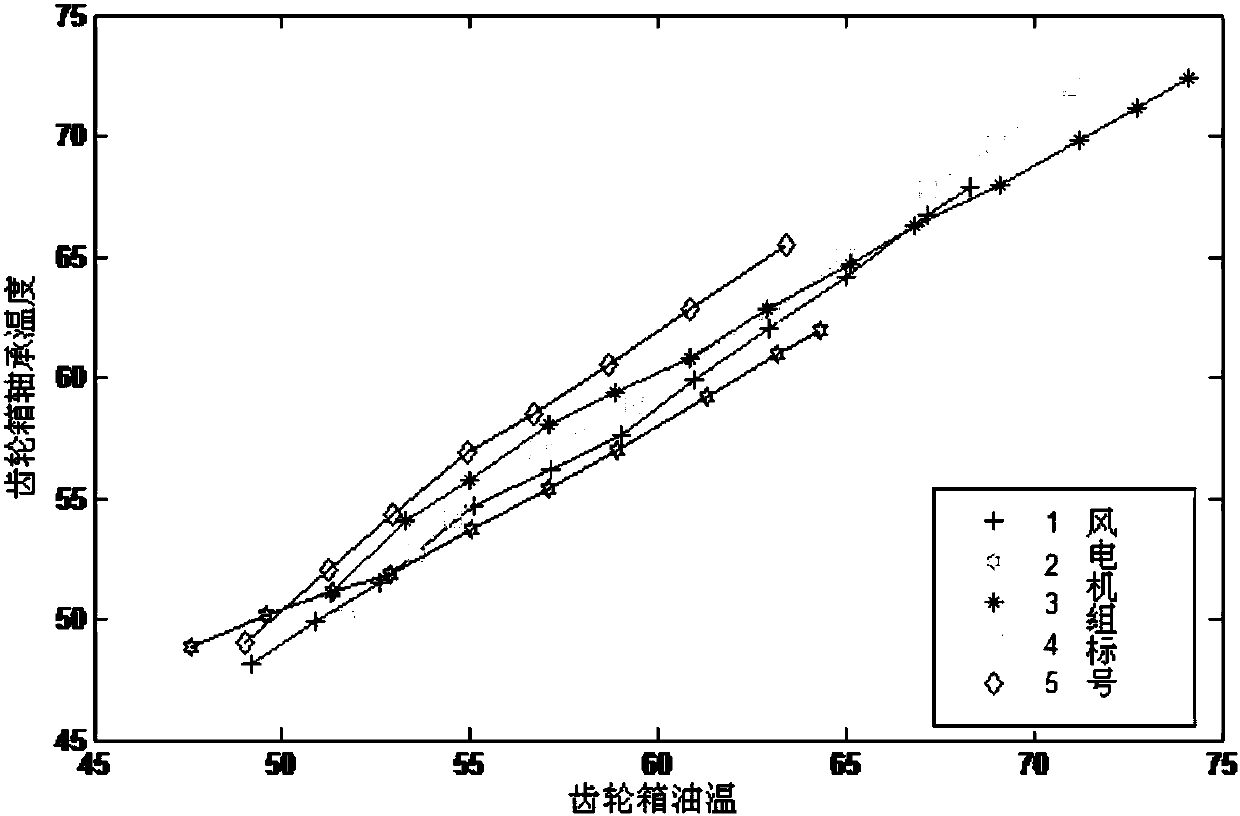

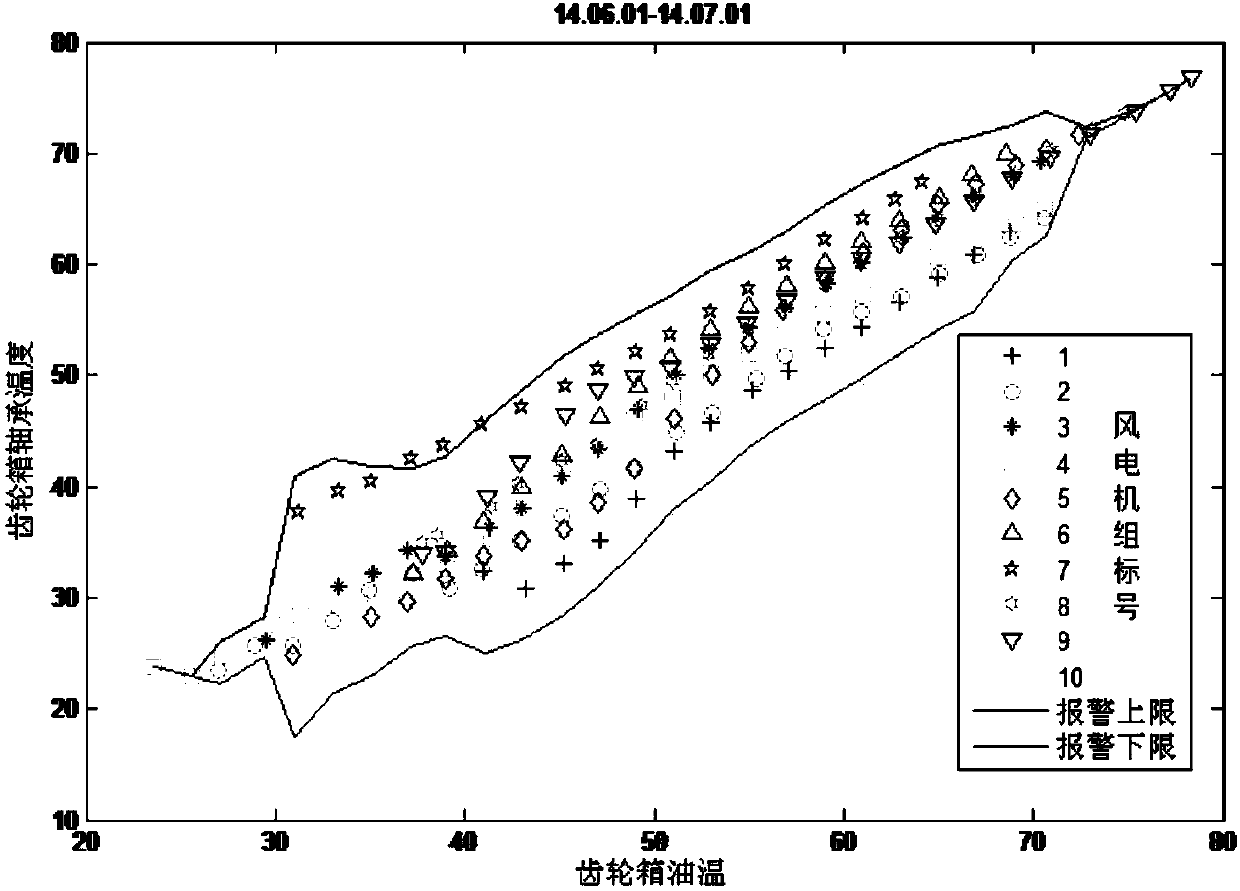

[0072] Step 5: cluster statistical analysis of target variable;

[0073] Step 6: Judgment of the state of the wind turbine.

[0074] The collection of described step 1SCADA operation data comprises:

[0075] Collect the data of at least 10 wind turbines of the same model in the same wind farm with a single calculation data period of not less than 1 day, and the data uses a 10-minute average value;

[0076] Verify the collected SCADA operation data to ensure the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com