Yarn deflection roller for mechanical yarn energy accumulator

A technology of deflection rollers and accumulators, which is applied in the field of yarn deflection rollers, and can solve problems such as component damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

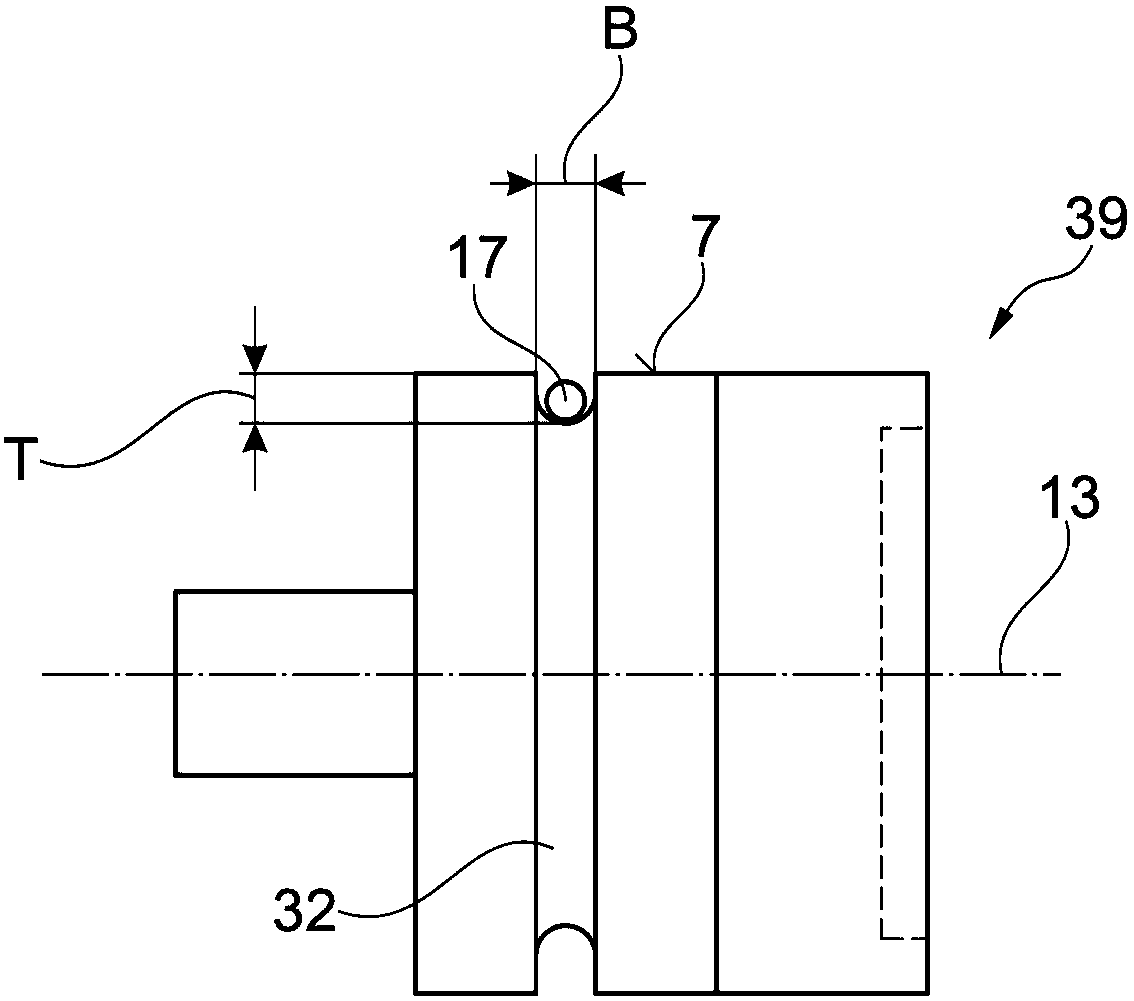

[0038] figure 1 A perspective elevational view of a highly schematic type is provided showing a workstation 10 of a textile machine (in the present example an open-end rotor spinning machine) producing cross-wound bobbins. As already disclosed, such an open-end rotor spinning machine has a large number of identically configured workstations 10 of this type, which are arranged next to each other in a row. At the workstation 10, a yarn 17 is spun in each case by means of an open-end rotor spinning device 12 from a so-called sliver held in a spinning pot (not shown) and subsequently in a winding device 18. The yarn 17 is wound into a cross-wound bobbin 19.

[0039]The winding devices 18 of such workstations 10 each have: a creel 8 for holding cross-wound bobbins 19 in a rotating arrangement; a yarn traversing device 22 with a traversing yarn guide 1 which For example, it may be driven by a single motor for traversing the yarn 17 running onto the cross-wound bobbin 1; and a bobb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com