Light rail vehicle for ascending assembly

A light rail and bottom rail technology, applied in the field of light rail vehicles, can solve the problems of high cost, inability to meet multi-directional movement, difficult transfer, etc., and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

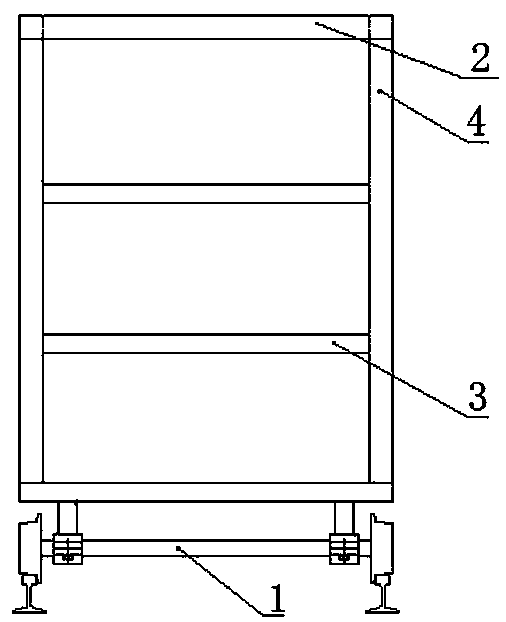

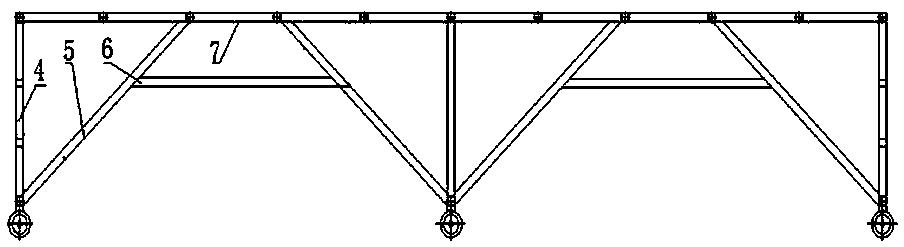

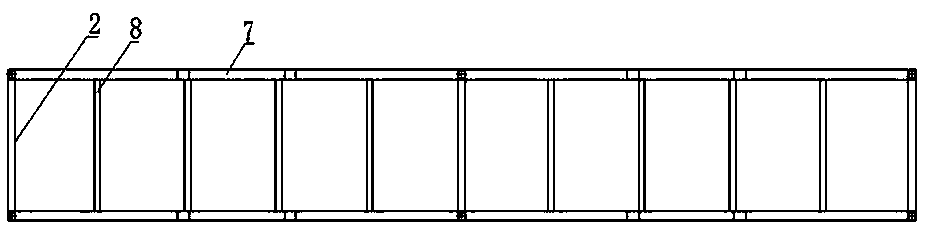

[0013] Such as Figure 1-3 Shown, a kind of light rail car that is used for ascending assembly comprises the upper frame that is made up of crossbeam 2 and longitudinal beam 7, and the support beam 4 that is used to support upper frame, and the bottom end of described support beam 4 is connected with The bottom rail 1, the longitudinal beam 7 and the supporting beam 4 are obliquely connected by the diagonal beam 5, the longitudinal beam 7 is connected by the connecting beam 8, and the upper end surface of the longitudinal beam 7 and the connecting beam 8 is laid with a support plate .

[0014] In a further solution, the support beams 4 at both ends are connected by pedals 3 .

[0015] In a further solution, adjacent diagonal brace beams 5 are connected by horizontally arranged reinforcement beams 6 .

[0016] The light rail vehicle of the present invention is a rectangular upper frame welded by rectangular tubes, and diagonal brace beams and reinforcing beams are welded in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com