Local adjusting method of bending machine deflection compensation workbench

A local adjustment and bending machine technology, applied in the field of bending machines, can solve the problems of poor consistency of the bending angle of the workpiece, poor straightness of the workpiece, etc., and achieve the effect of convenient operation and reduced manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

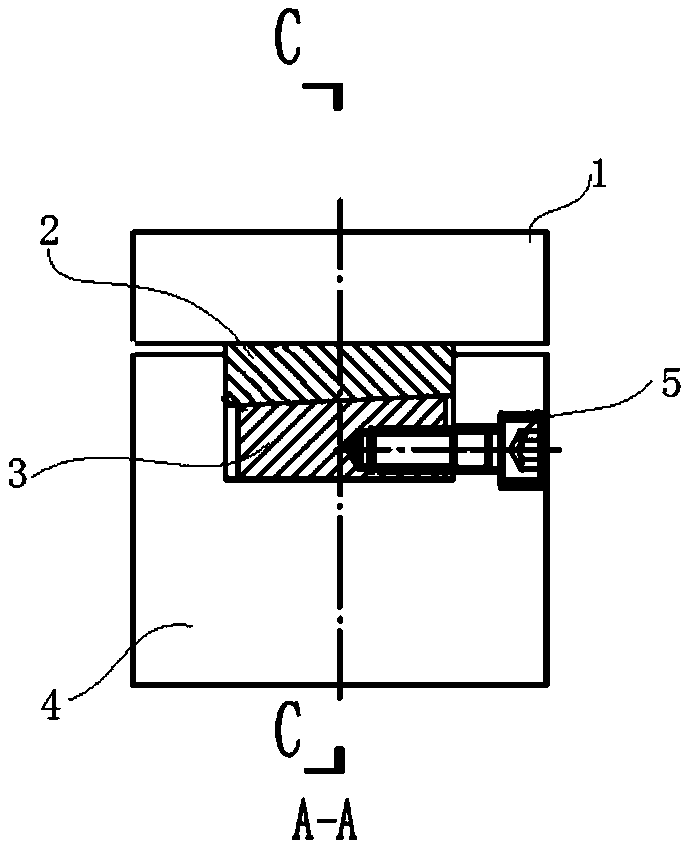

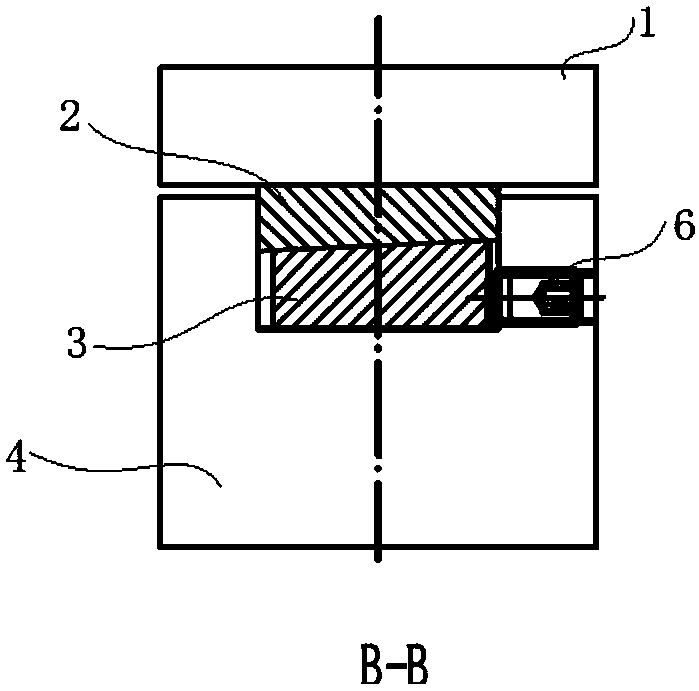

[0041] combine figure 1 , figure 2 , image 3 , Figure 4 and Figure 5The bending machine deflection compensation workbench that can be locally adjusted in this embodiment includes a cover plate 1, a base 4, a slide mechanism and an adjustment mechanism. The base 4 is provided with a rectangular groove along the longitudinal direction, and a slide mechanism is arranged in the rectangular groove. The cover plate 1 is placed above the slide plate mechanism. The slide plate mechanism includes an upper slide plate 2 and a lower slide plate 3, wherein: the upper slide plate 2 is an integral structure, and the lower slide plate 3 is an integral structure. The upper slide plate 2 is placed above the lower slide plate 3, and the lower surface of the upper slide plate 2 and the upper surface of the lower slide plate 3 are longitudinally provided with several pairs of slopes with correspondingly equal upper and lower slopes. decreasing at both ends. The lower surface of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com