Material blending device for hazel grouse rapid reproduction feed

A fast and feed technology, applied in the fields of feed, food science, application, etc., can solve the problems of small growth effect of flying dragon, inaccurate ingredients, slow breeding of flying dragon, etc., to improve weighing accuracy and batching efficiency, and ensure the quality of feed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

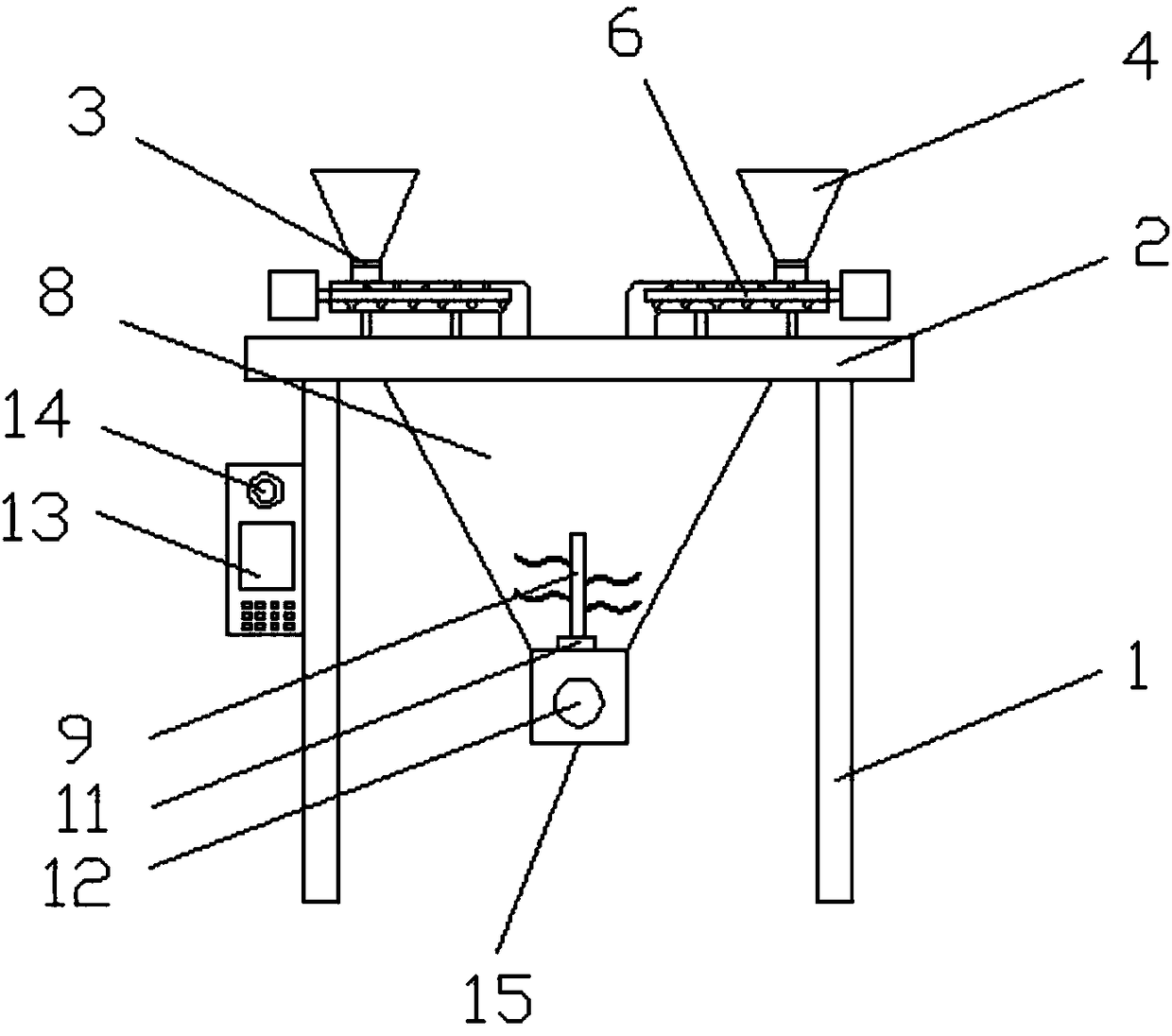

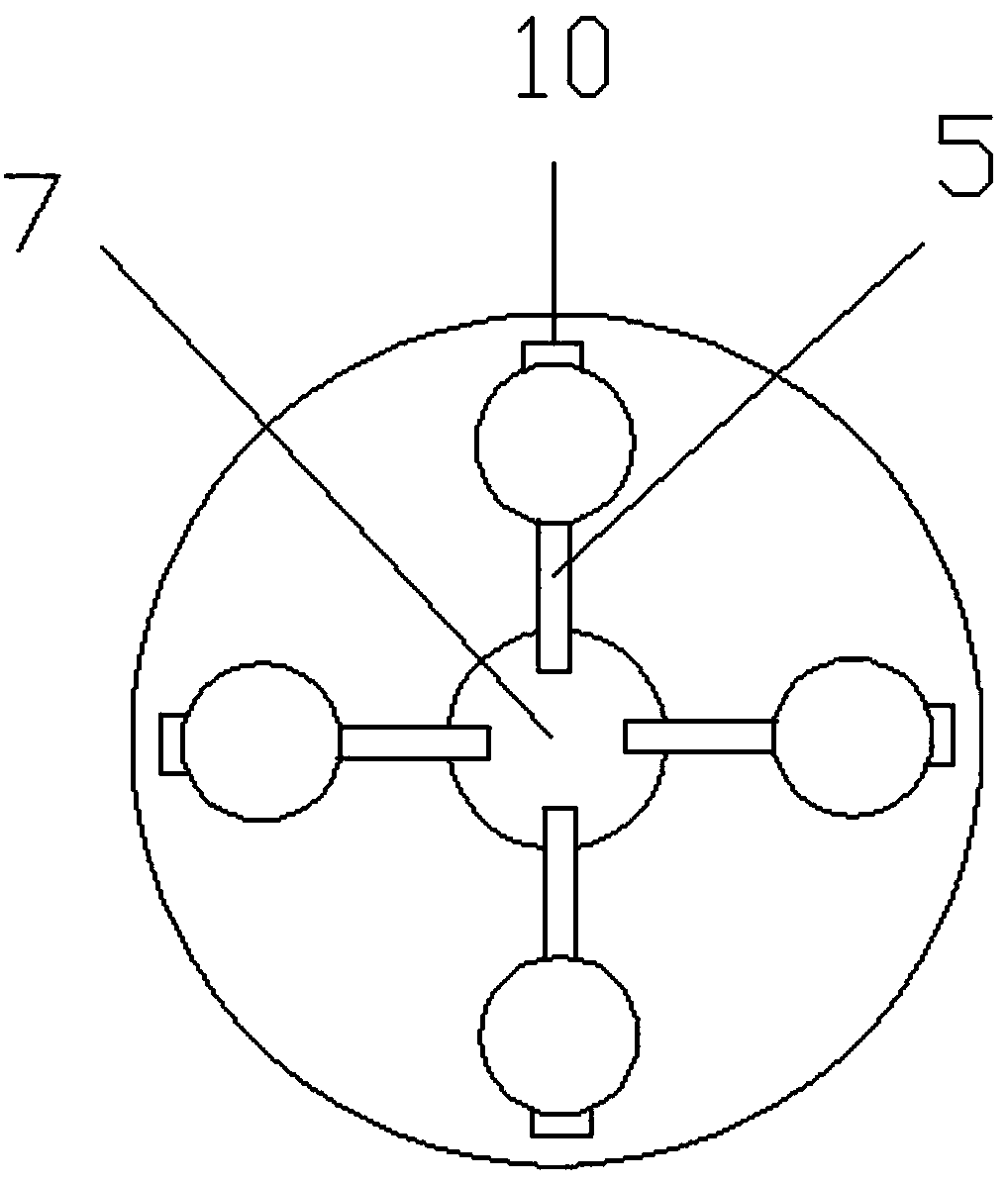

[0016] like Figure 1-2 As shown, a feed batching device for rapid breeding of flying dragons in this embodiment includes a load cell 3, a weighing hopper 4, a screw feeder 5 and a batching workbench 2, and is characterized in that: the batching workbench 2 is circular Structure, the bottom of the batching workbench 2 is provided with three supporting columns at equal intervals on the same circumference, the center of the batching workbench 2 is provided with a batching through hole 7, and the bottom of the batching through hole 7 is provided with a mixing hopper 8, and the mixing The hopper 8 is welded on the bottom of the batching workbench 2, and a screw feeder 5 is installed above the batching workbench 2, and a screw feeder 5 is provided inside the screw feeder 5, and the screw feeder 6 is connected to a drive motor 10 A weighing hopper 4 is installed on the screw feeder 5, and a weighing sensor 3 is arranged in the weighing hopper 4, and the weighing sensor 3 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com