Distributed residual current measuring system

A residual current and measuring system technology, applied in the direction of measuring devices, measuring only current, measuring electrical variables, etc., can solve the problems of long time, manual operation only, no data correlation, etc. good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

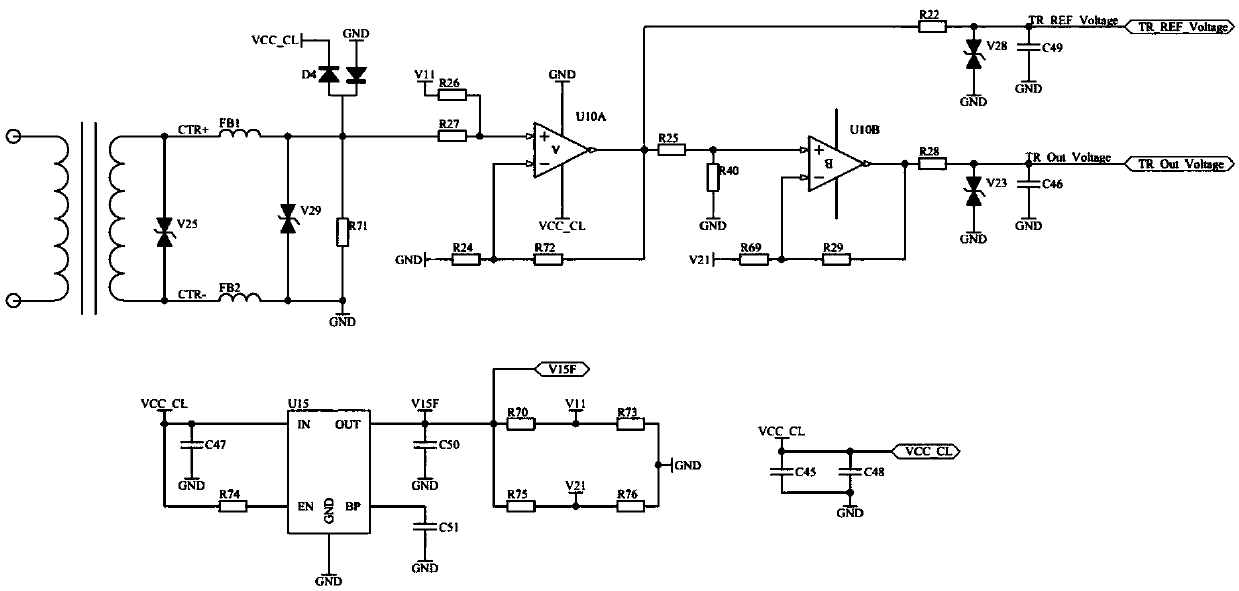

[0030] see Figure 1-7 , the present invention provides a technical solution:

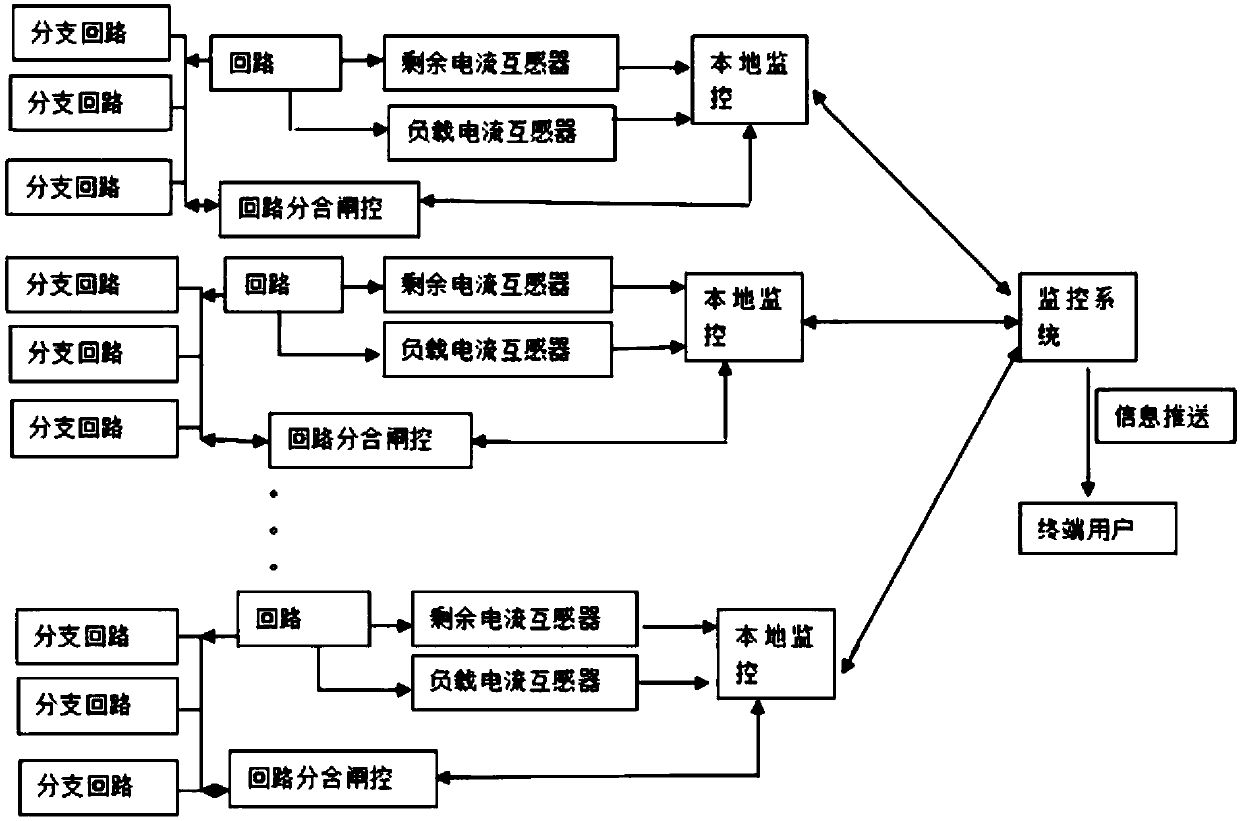

[0031] A distributed residual current measurement system, including several loops and a monitoring system, each loop is provided with several branch loops; each loop is equipped with

[0032] A residual current transformer, which is used to detect the residual current in the circuit;

[0033] a load current transformer, which is used to detect the load current in the loop;

[0034] Local monitoring, which interacts the real-time data of the residual current transformer and load current transformer with the background monitoring system, and controls the opening and closing of the circuit;

[0035] Opening and closing of the circuit, which controls the opening and clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com