Supporting seat for fixing and lifting digital camera

A technology of lifting support base and digital camera, which is applied in the direction of machine platform/bracket, supporting machine, mechanical equipment, etc. It can solve the problems of unable to meet the requirements of taking pictures, no connecting screw holes, and unable to realize connection support, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

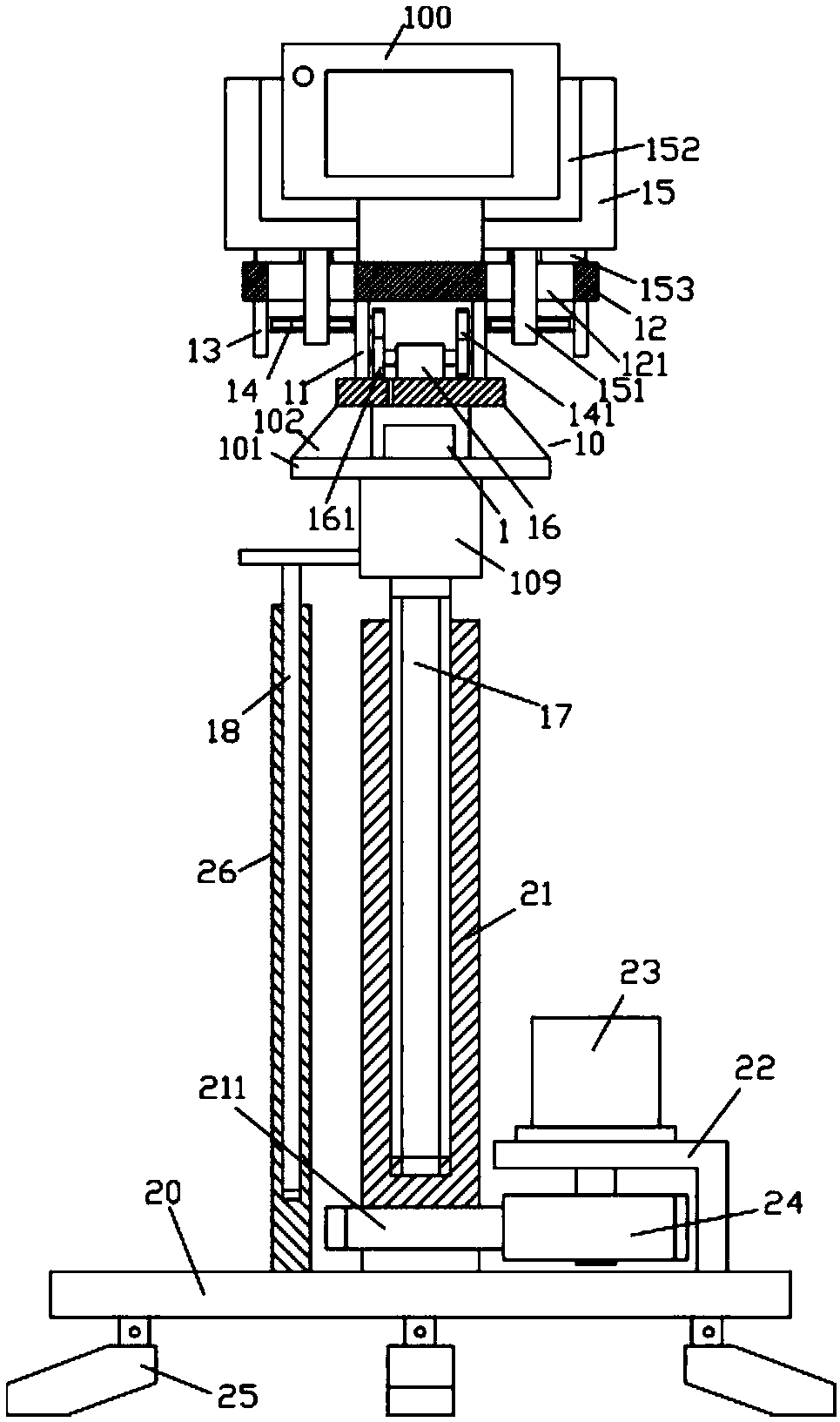

[0017] Examples, see e.g. figure 1 As shown, a digital camera fixed lifting support base includes a base 10, a connecting block 109 is fixed on the bottom surface of the middle part of the lower connecting plate 101 of the base 10, and a vertical screw rod 17 is fixed on the middle part of the bottom surface of the connecting block 109, and the mobile base plate 20 The top surface of the middle part is hinged with a vertical screw sleeve 21, and the vertical screw rod 17 is screwed in the vertical screw sleeve 21. The top surface of the mobile base plate 20 is fixed with a motor support frame 22, and the top plate of the motor support frame 22 is fixed with a lifting motor. 23. The output shaft of the lifting motor 23 passes through the bottom surface of the top plate of the motor support frame 22 and is fixed with a lifting gear 24. The lower part of the lifting gear 24 and the vertical screw sleeve 21 is fixed with a bottom transmission gear 211. The lifting gear 24 and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com