Compressor vibration reduction assembly, compressor assembly and air conditioner

A technology of vibration damping components and compressors, which is applied in the direction of machines/engines, pump components, mechanical equipment, etc., can solve problems such as inaccurate positioning, and achieve the effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

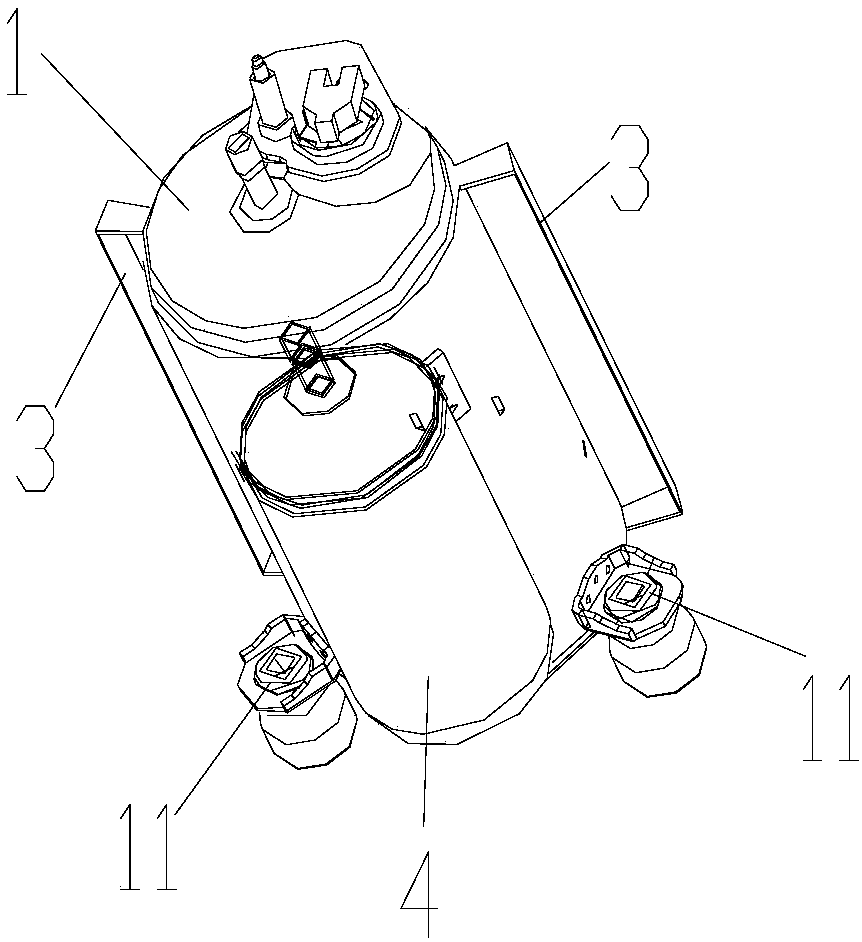

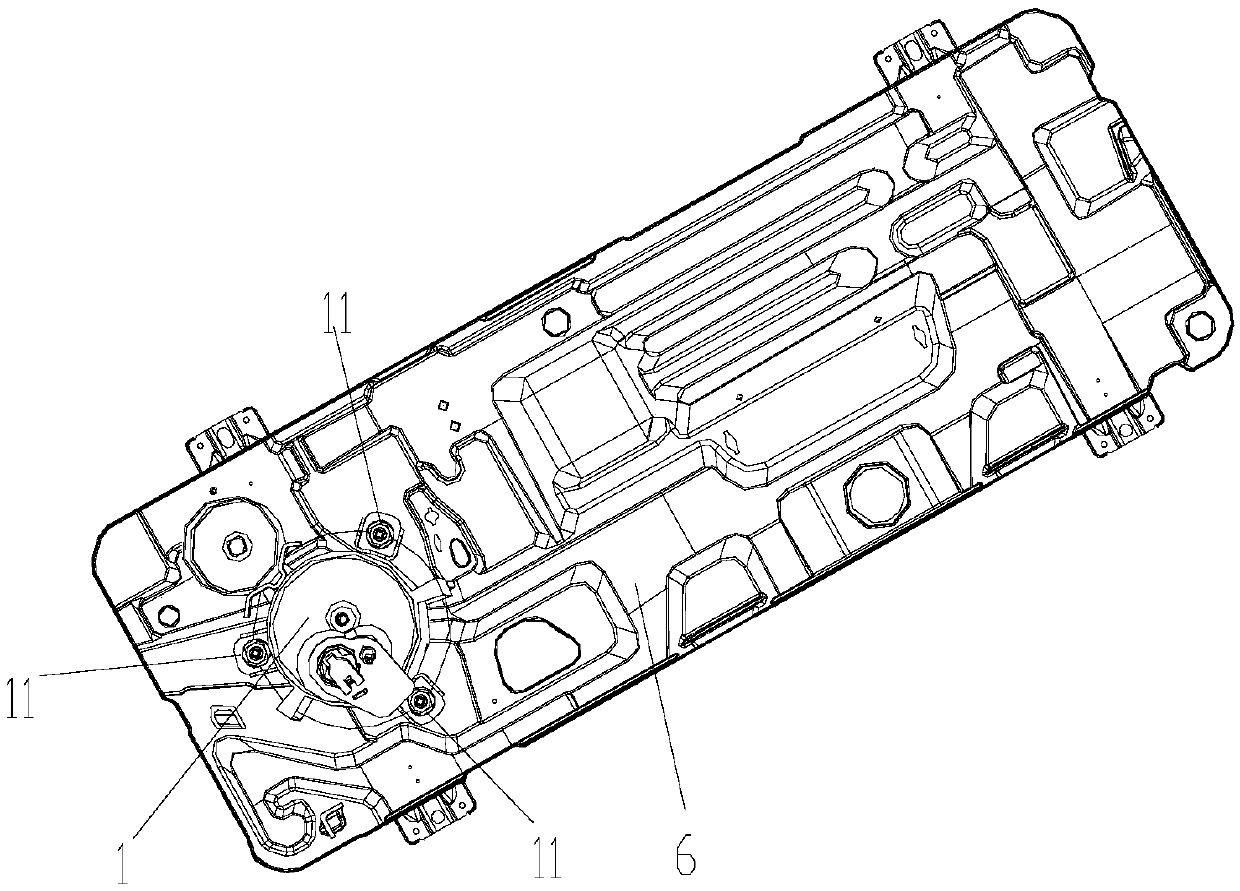

[0049] Such as Figure 1-8 As shown, the present invention provides a compressor damping assembly, which includes:

[0050] The damping component 2 is capable of wrapping the shell of the compressor 1;

[0051] The positioning component 3 is arranged on the casing of the compressor 1 and protrudes outwards, and can allow the vibration damping component 2 to pass therethrough so as to position the vibration damping component 2 in the axial direction of the compressor.

[0052] The compressor shell can be wrapped by the vibration damping component; the positioning component is arranged on the compressor shell and protrudes outward, and can allow the vibration damping component to pass therethrough, so as to fix the vibration damping component on the compressor Positioning in the axial direction enables the vibration-damping components to be accurately and effectively positioned during installation, which solves the problem of packaging difficulties caused by inaccurate position...

Embodiment 2

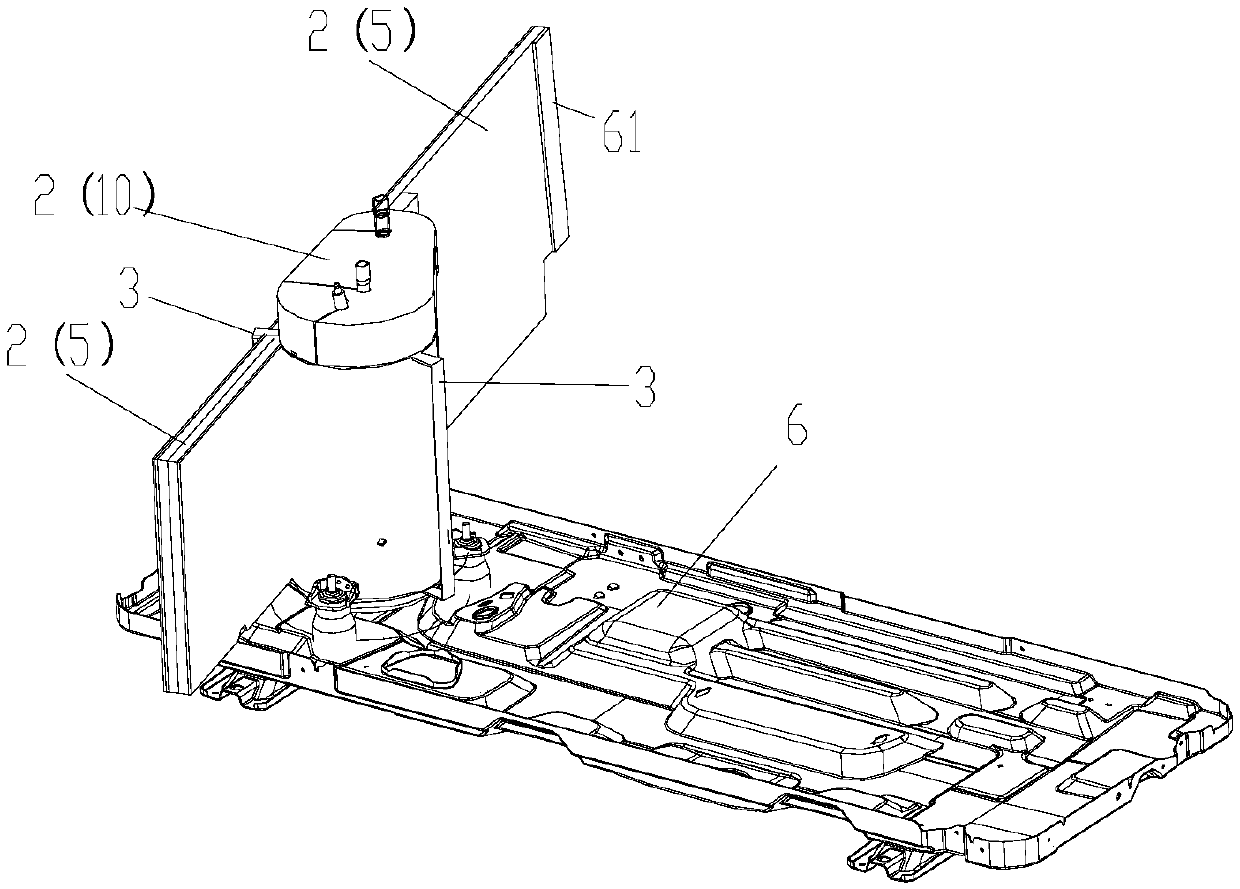

[0060] This embodiment is a further improvement on the basis of Embodiment 1, preferably,

[0061]The vibration damping member 2 includes a peripheral sound-insulating member 5 capable of wrapping the peripheral surface of the compressor 1 and the peripheral surface of the liquid storage tank 4 at the same time, and the peripheral sound-insulating member 5 can be separated from the The positioning part 3 passes through to be positioned and installed. This is a further preferred structural form of the vibration-damping component of the present invention, and the sound-insulating component can wrap the peripheral surfaces of the compressor and the liquid storage tank through the weekend to effectively reduce vibration.

[0062] Preferably,

[0063] The surrounding sound-insulating component 5 includes a high-frequency sound-absorbing layer structure 51 and a low-frequency sound-absorbing layer structure 52, and the low-frequency sound-absorbing layer structure 52 covers part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com