Thickness and tension decoupling control method and system for single stand cold rolling mill

A technology of decoupling control, cold rolling mill, applied in rolling mill control device, tension/pressure control, driving device for metal rolling mill, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described below in conjunction with specific examples and drawings.

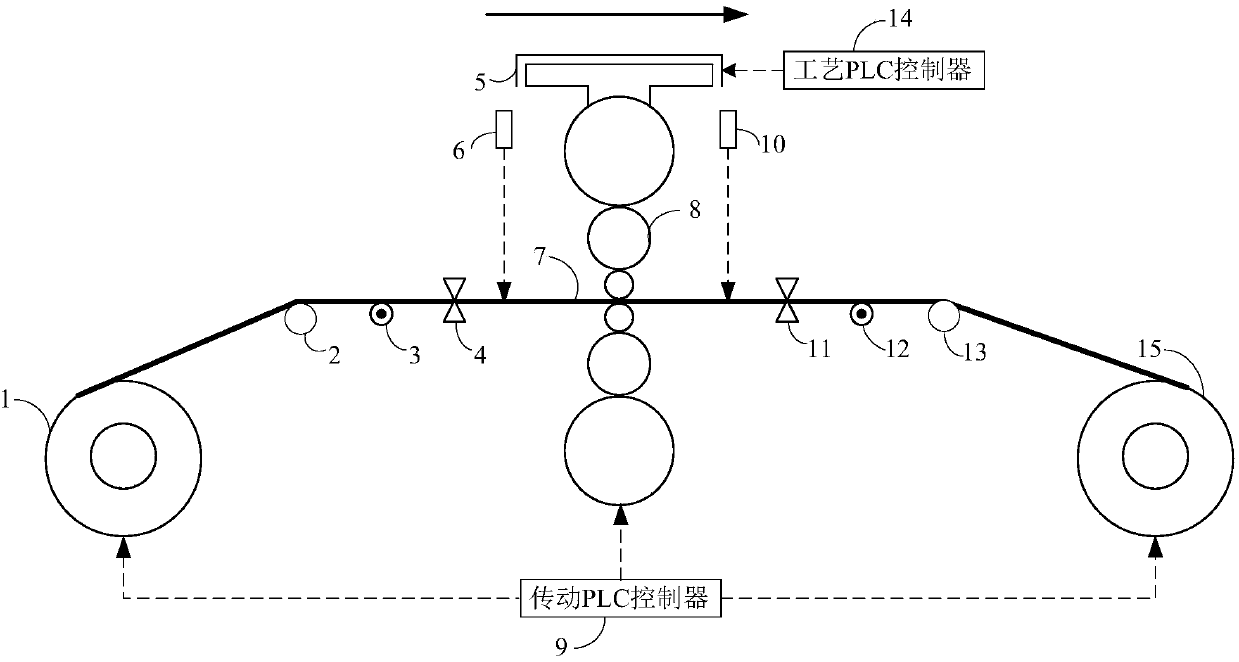

[0073] Such as figure 1 As shown, the strip steel 7 is uncoiled from the entrance coiler 1, passes through the entrance turning roll 2 and then enters the six-high rolling mill 8 for rolling. After rolling, it passes through the exit turning roll 13 and is coiled on the exit coiler 15. 7 Thickness control is programmed in the process PLC controller 14. The process PLC controller 14 controls the hydraulic cylinder 5 to provide rolling force to roll the strip steel 7 to the required thickness; the inlet and outlet are configured to measure the thickness of the strip steel 7 in and out The entrance and exit thickness gauges 4 and 11 are equipped with an entrance tension meter 3 and an exit tension meter 12 for measuring the tension of the strip steel 7 at the entrance and exit; the entrance and exit speeds of the strip 7 are determined by the entrance laser speed meter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com