Laser marking focusing device

A laser coding and focusing device technology, applied in the field of manual focusing, can solve the problems of large manpower consumption, low efficiency, inconvenient operation, etc., and achieve the effect of simple operation, high efficiency and high focusing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

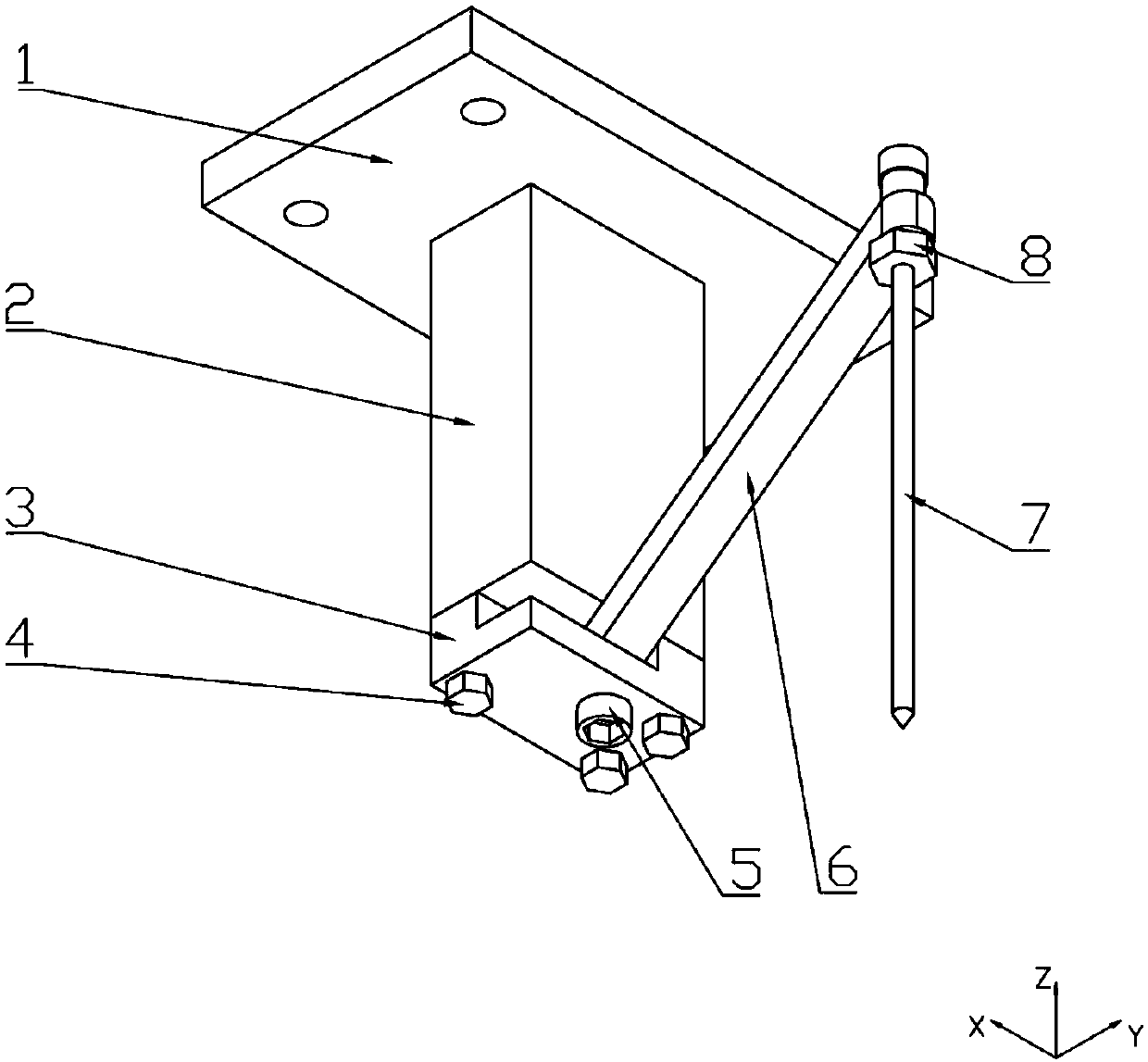

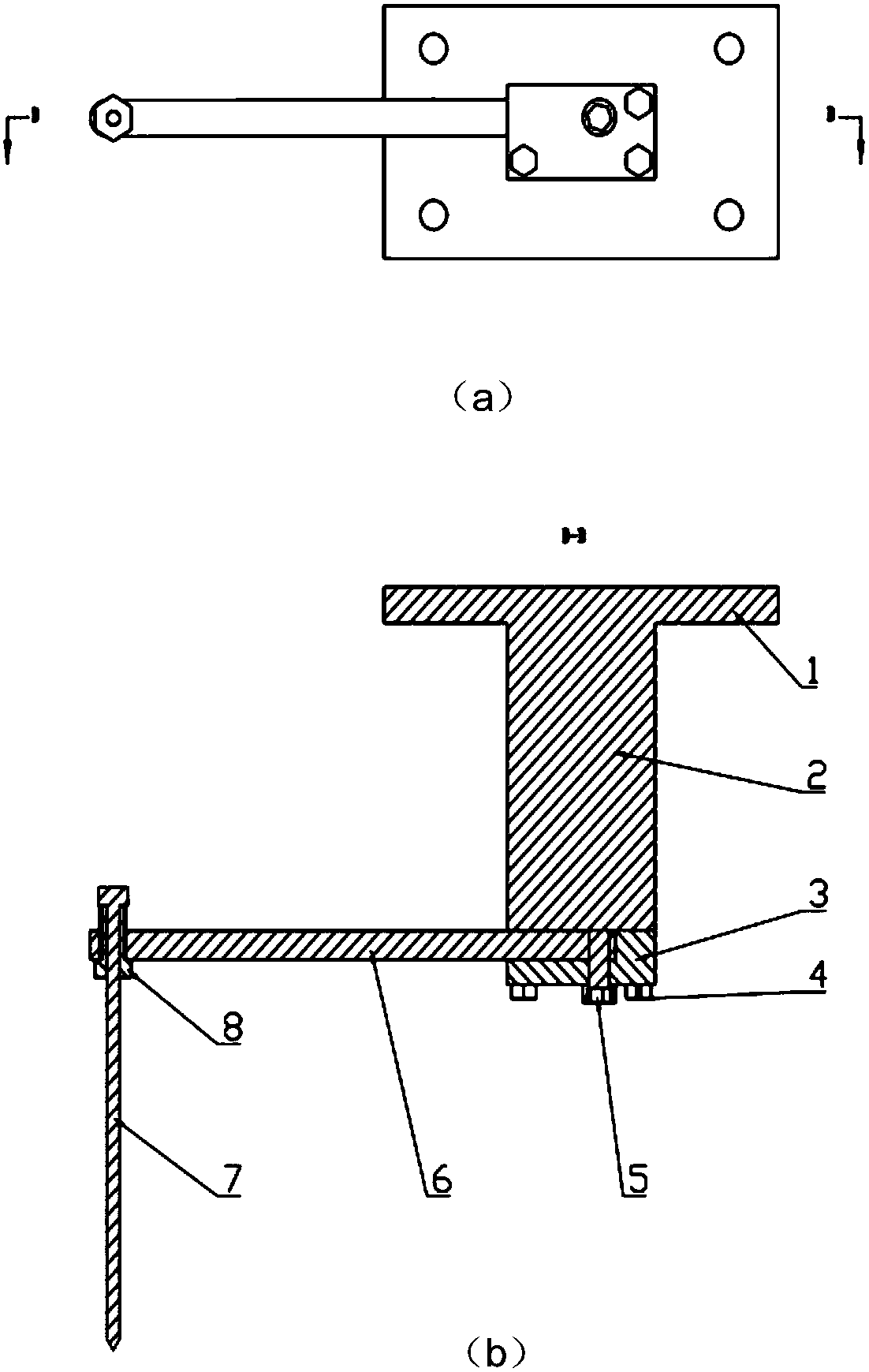

[0030] This embodiment provides a laser marking focusing device, including:

[0031] Connecting plate: Its function is mainly to fix the entire focusing device, and adjust the positions of the x and y planes through the positions of the four connecting through holes.

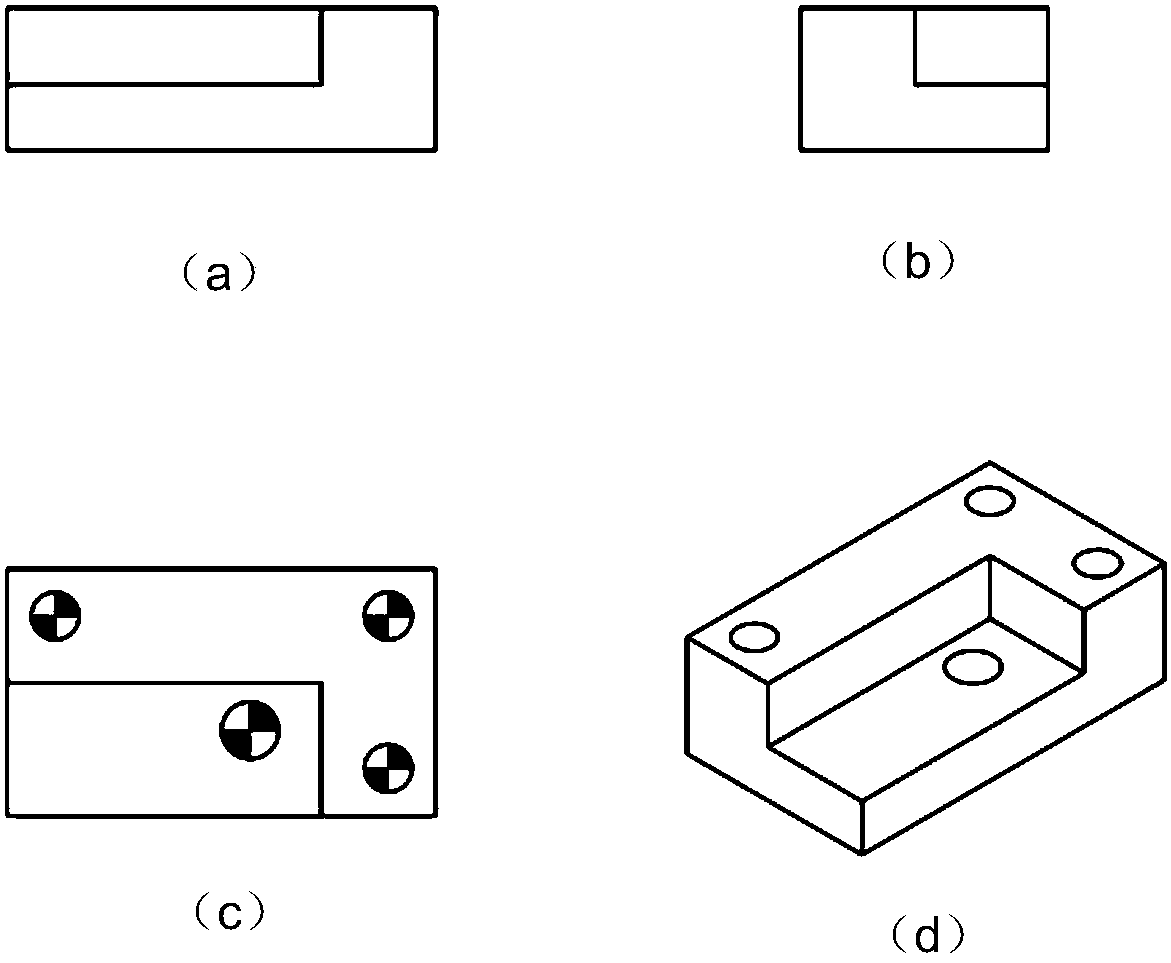

[0032] Cover plate: connected to the column by screws, with a rectangular groove for the installation of rotating pins and beams.

[0033] Beam: One end is fixed by a rotating pin, and the other end is a screw hole structure.

[0034] Guide sleeve: the external thread is connected to the beam, and there is a central through hole in the center.

[0035] Slider pointer: installed in the center through hole of the guide sleeve.

[0036] There is a pin hole in the middle of the cover plate, wherein a rotating pin is installed in the pin hole, and a crossbeam is installed on the rotating pin. Due to the limitation of the cover plate, the beam can be rotated at a certain angle. When the rotation angle is too large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com