Device allowing engine component to rotate to be assembled

An engine and component technology, applied in the field of aero-engine assembly, can solve the problems of discoloration of dishes, inability to rotate, and large diameter of the round table, and achieve the effect of reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings of the description, please refer to Figure 1~2 .

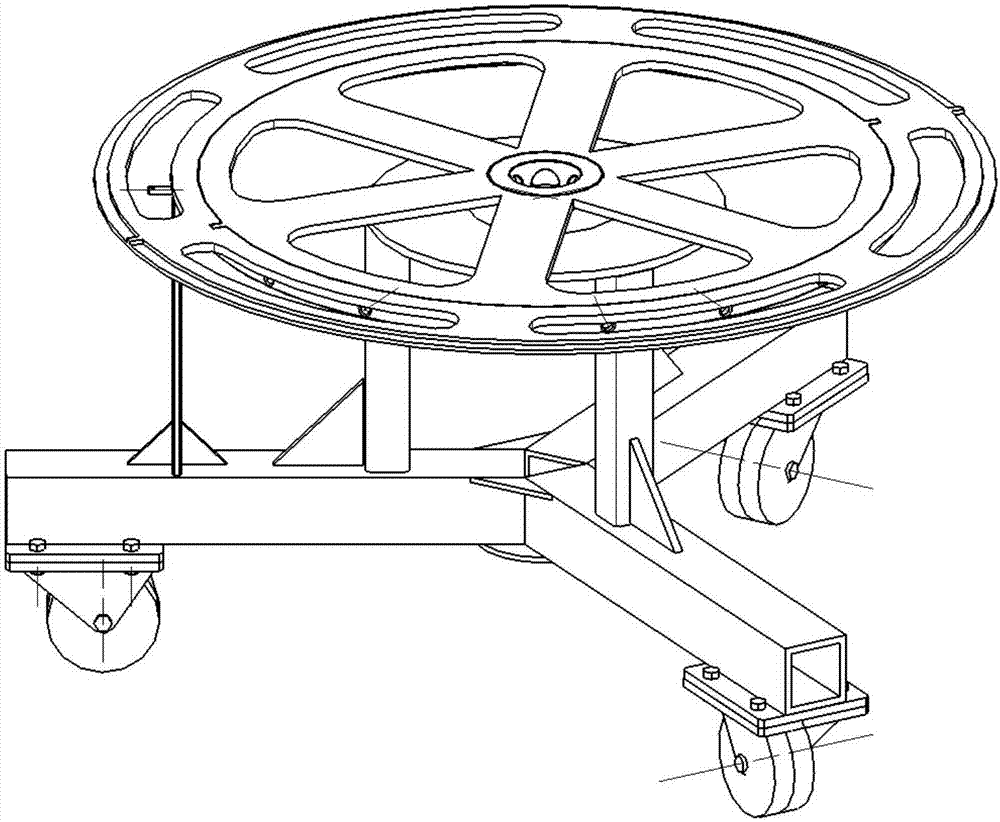

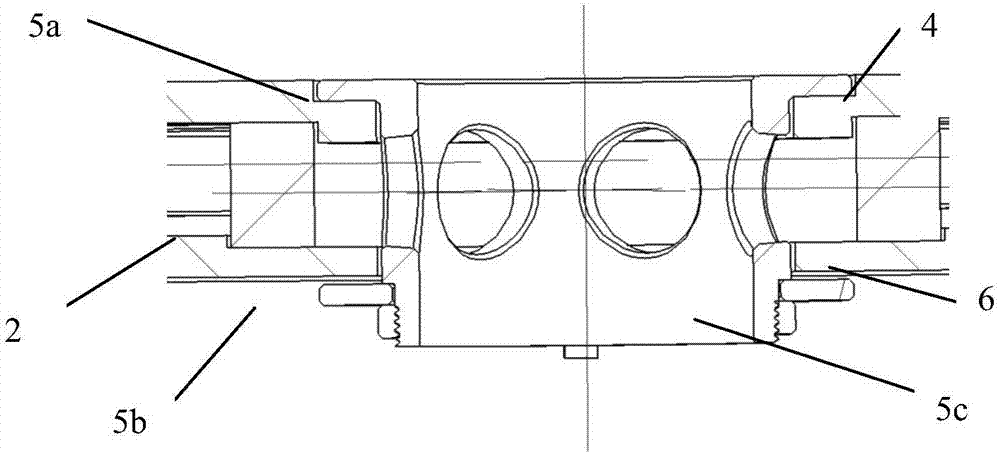

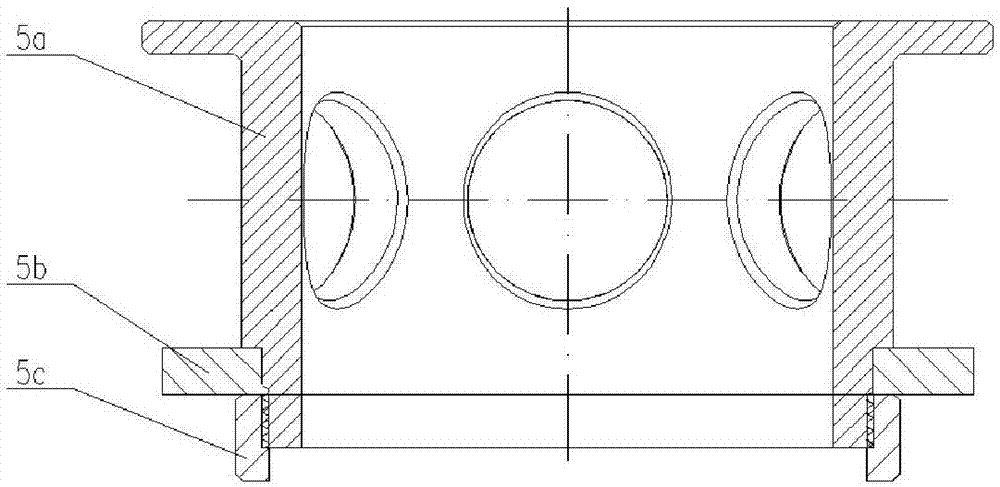

[0021] figure 1 Shown is a structural diagram of a device capable of rotatably assembling engine parts according to the present invention. The device includes an extension ring 1, a thrust bearing 2, a stop pin 3, a rotating disc 4, a pressing device 5, a platform main body 6, and casters 7. Wherein, the rotating disk 4 is connected through the pressing device 5 and the thrust bearing 2, and the workpiece to be assembled is placed on the upper surface of the rotating disk 4 to realize the rotating function. When the rotating disk 4 rotates to a certain angle and needs to stop reliably, the stop pin 3 is inserted into the pin hole to ensure that the rotating disk 4 does not rotate any more. The platform main body 6 bears the gravity of the workpiece. The extension ring 1 is used to meet the assembly requirem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com