Plug seedling plantation driving mechanism

A driving mechanism and a technology for plug seedlings, which are applied to the field of plug seedling planting mechanisms and plug seedling planting drive mechanisms, can solve the problems of duckbill peeling, returning seedlings, and too large hole punching holes, and can achieve hole punching. Small orifice, improve the uprightness of pot seedlings, and reduce the effect of tearing film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

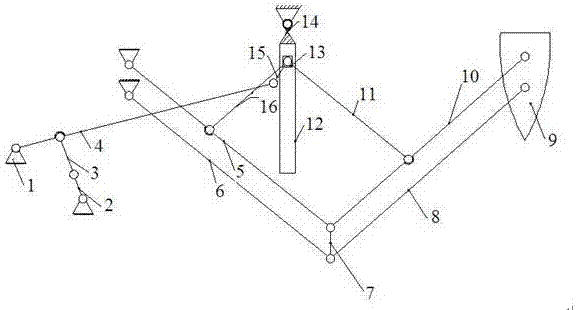

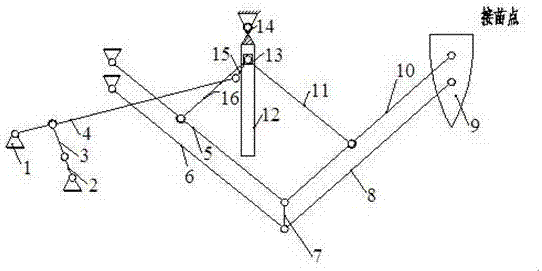

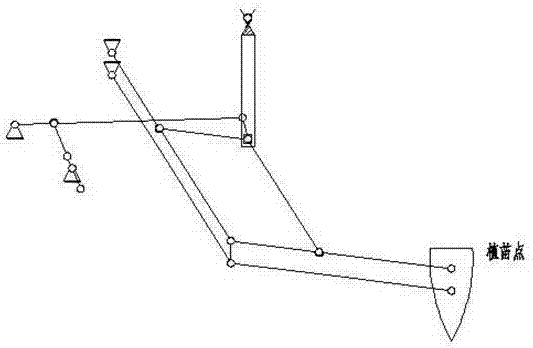

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] Such as Figures 1 to 3 Shown, a kind of hole tray seedling planting drive mechanism, it comprises frame 1 and crank 2, and one end of described crank 2 and first connecting rod 3 is connected to form revolving pair, the other end of first connecting rod 3 and rocking bar 4 Connected to form a revolving pair, one end of the rocking rod 4 is connected to the frame 1, and the other end is connected to the second connecting rod 15 to form a revolving pair, the second connecting rod 15 is connected to the slider 13 at the same time, and the rocking rod and the rocking rod are connected to each other through the second connecting rod. The sliders in the slideway are connected to convert the swing of the rocker into the linear motion of the slider.

[0020] The slide block 13 is placed in the slideway 12 to form a moving pair, and the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com