Locking and disengaging structure used for gun cartridge magazine and having two-way operation function

A two-way operation and magazine technology, applied in the field of firearms, can solve the problems of reducing the speed of changing magazines for users, operating comfort, and unsmooth operation, and achieve the effect of improving speed and operating comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

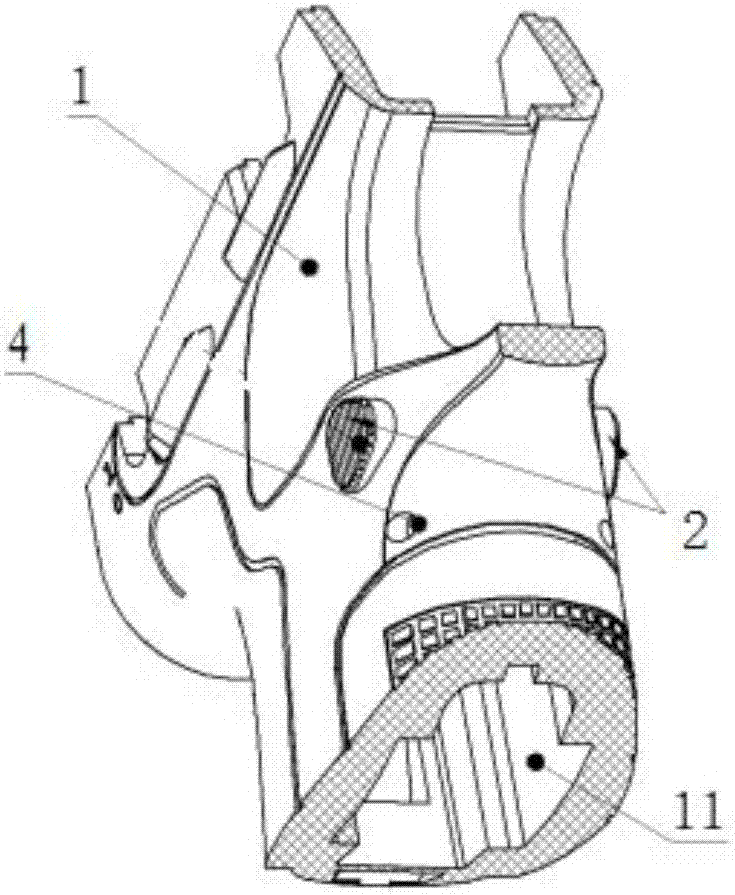

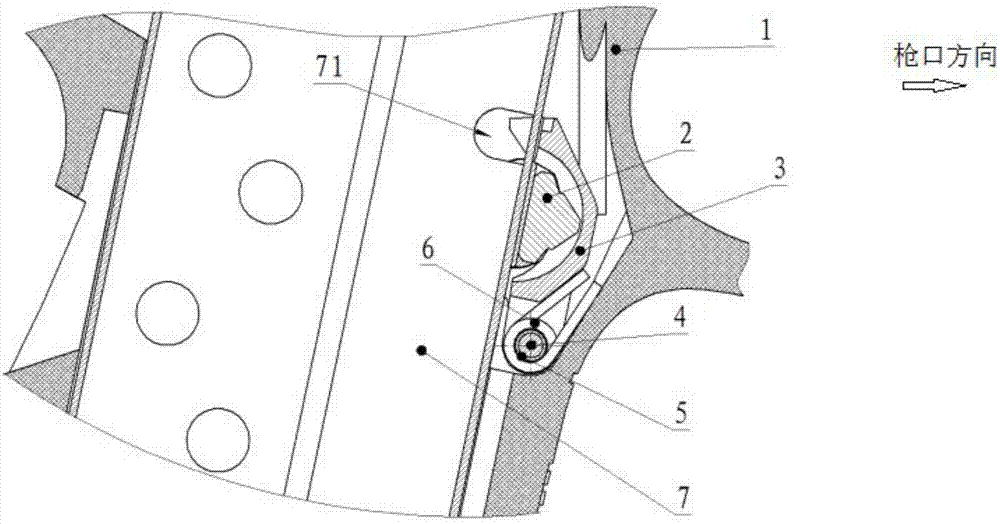

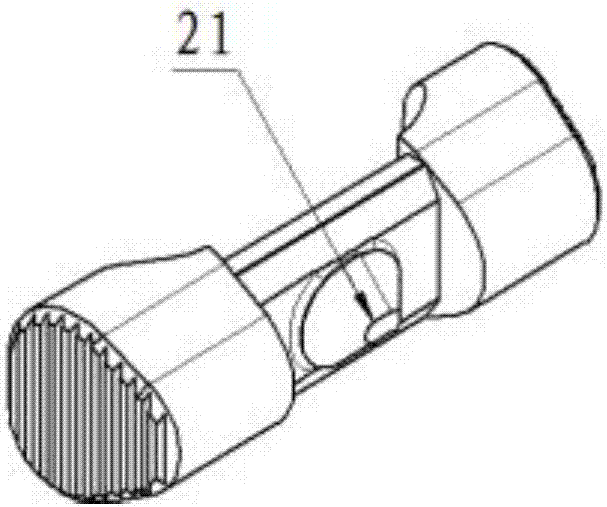

[0031] see Figure 1-Figure 13 , an embodiment of the two-way locking and releasing structure of the pistol magazine, an embodiment of the two-way locking and releasing structure of the pistol magazine, including a handle 1, and the front wall of the magazine slot 11 of the handle 1 is provided with There is a groove 14 (pointing to the front in the direction of the muzzle), the left and right side walls of the groove 14 are pierced with a magazine tenon pin 4, a magazine buckle 2 that can move left and right, and the magazine tenon pin 4 is worn on the top. A torsion spring 6 and a magazine tenon 3 that can be turned back and forth are provided. One spring foot of the torsion spring 6 is in contact with the magazine tenon 3, and the other spring foot of the torsion spring 6 is in contact with the groove bottom of the groove 14. Then, the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com