olive oil making equipment

A technology of olive oil and equipment, which is applied in the field of olive oil production equipment, can solve the problems affecting the quality of olive oil and the quality of branches, and achieve the effects of reducing residual sundries, good effect and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further detailed explanation through specific implementation mode below:

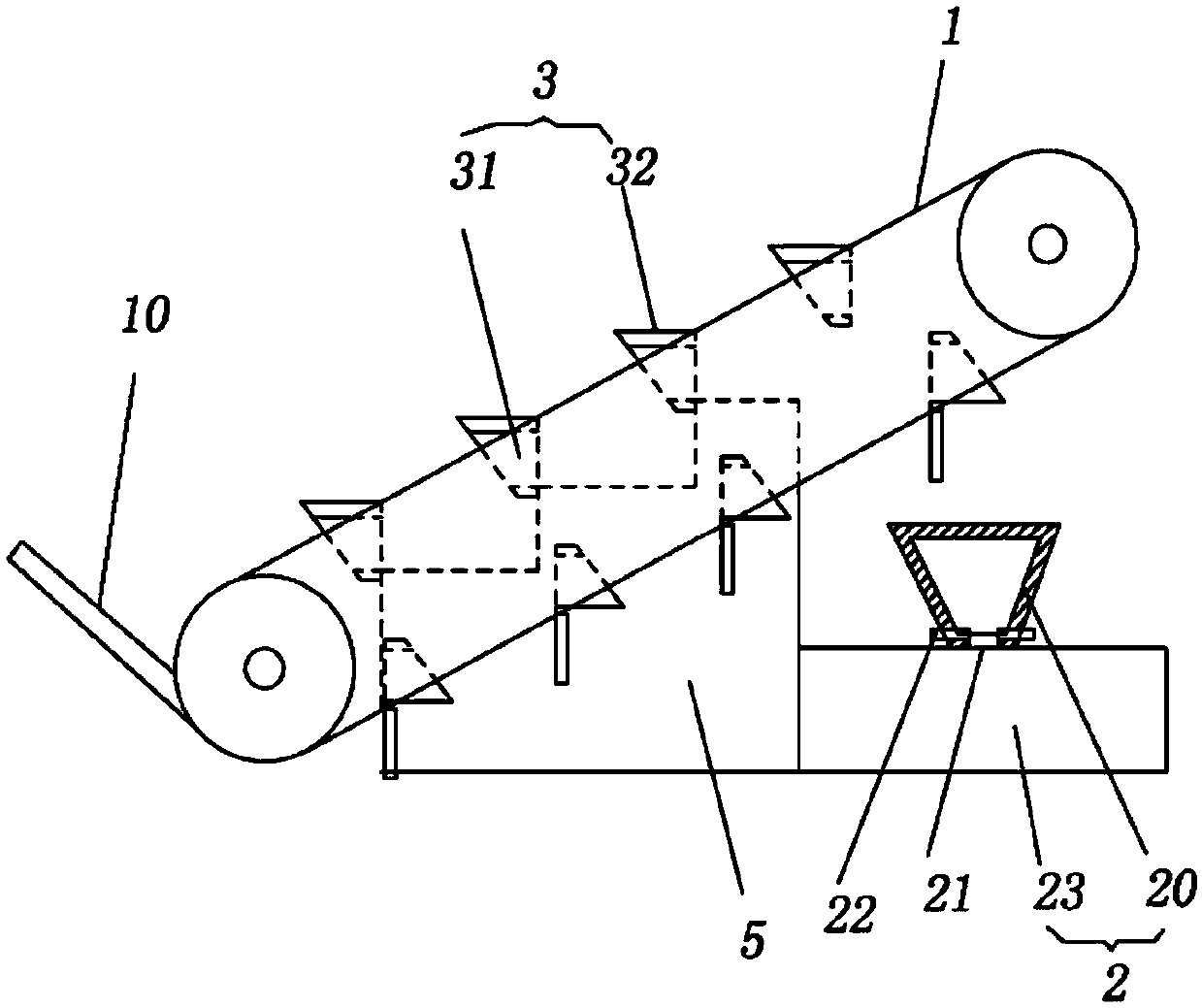

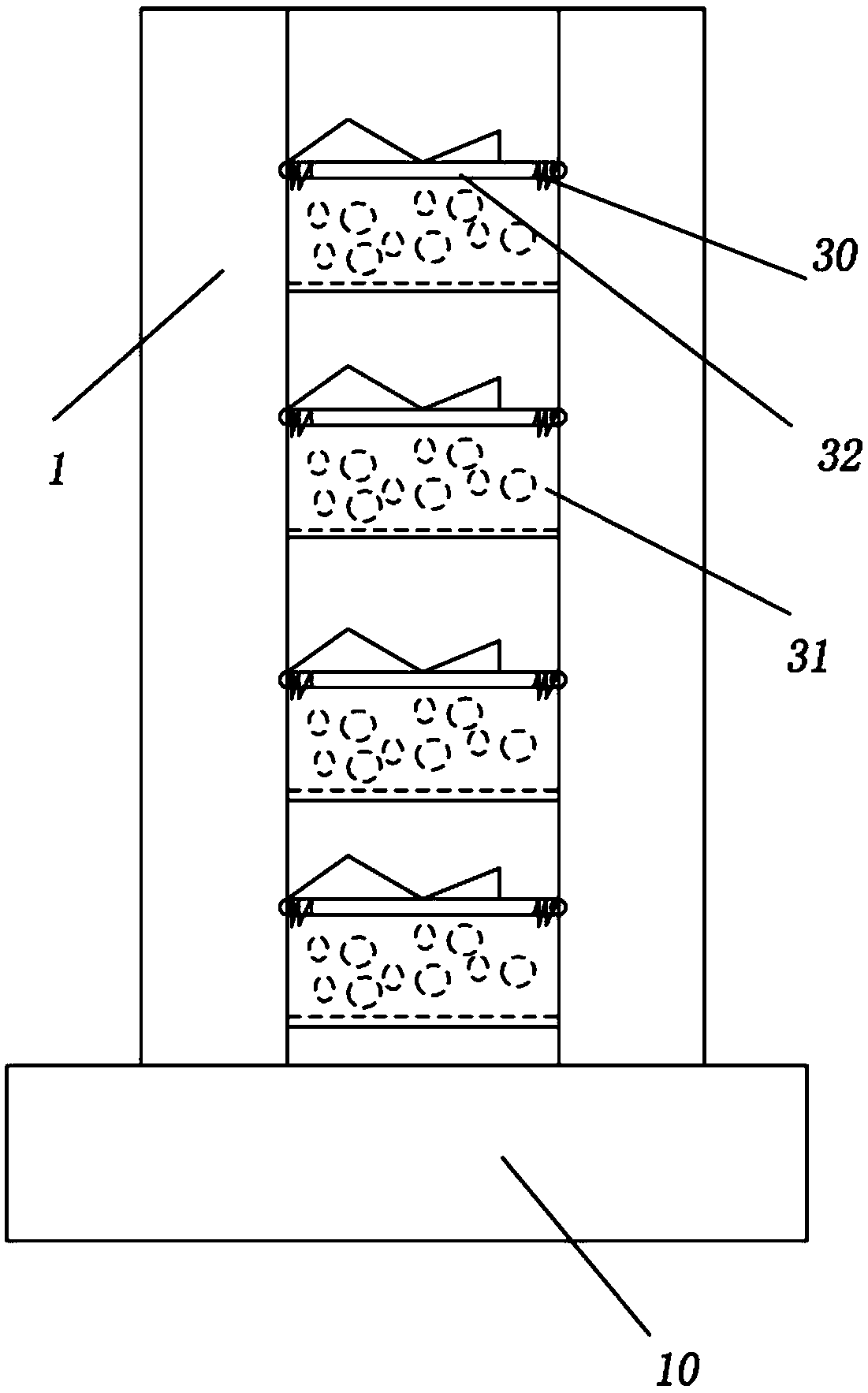

[0020] The reference signs in the drawings of the description include: conveyor belt 1, feeding plate 10, pruning box 2, pruning chamber 20, through hole 21, blade 22, fruit chamber 23, carrying box 3, torsion spring 30, fruit chamber 31 , cover plate 32, glove box 5.

[0021] The embodiment is basically as attached figure 1 And attached figure 2 Shown: olive oil production equipment, including a conveyor belt 1, pruning boxes 2 and several carrying boxes 3; the conveyor belt 1 is arranged obliquely from bottom to top. A torsion spring 30 is connected between the two ends of the carrier box 3 and the conveyor belt 1, and several carrier boxes 3 are evenly distributed on the conveyor belt 1; the carrier box 3 includes a fruit chamber 31 and a cover plate 32 hinged on the top of the fruit chamber 31 , Cover plate 32 is provided with the sieve hole that is used to separate fruit and leaf, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com