Folding and stacking device for packaging carton box

A technology for stacking devices and cartons, applied in the field of production auxiliary folding and stacking devices, which can solve problems such as downtime, equipment failure, waste of artificial paths, etc., and achieve the effects of simple overall structure, strong practicability, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

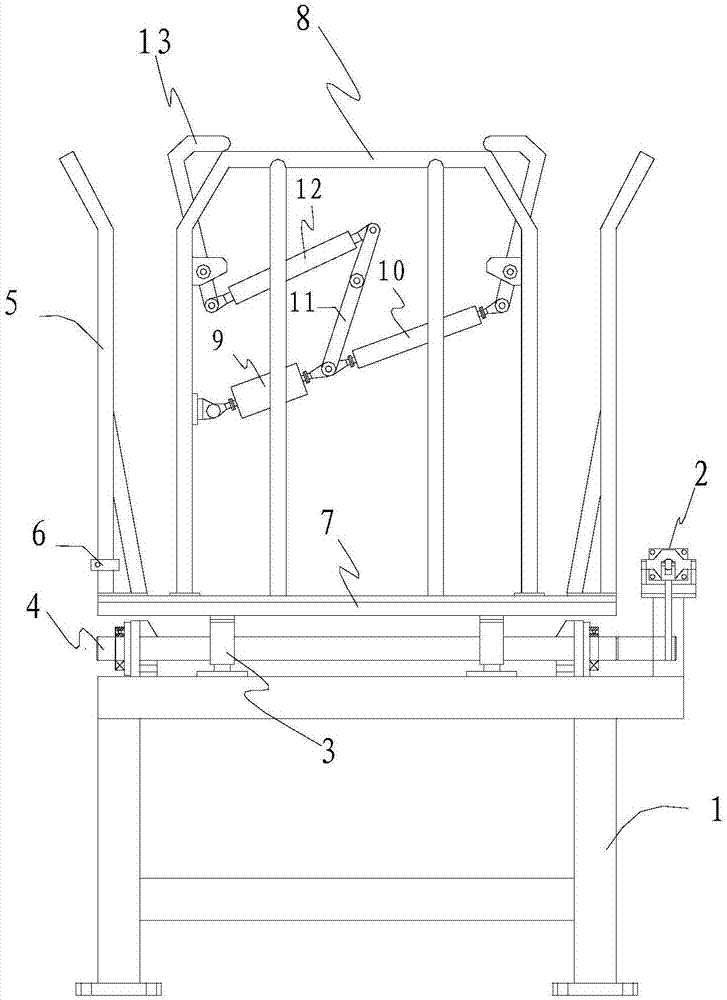

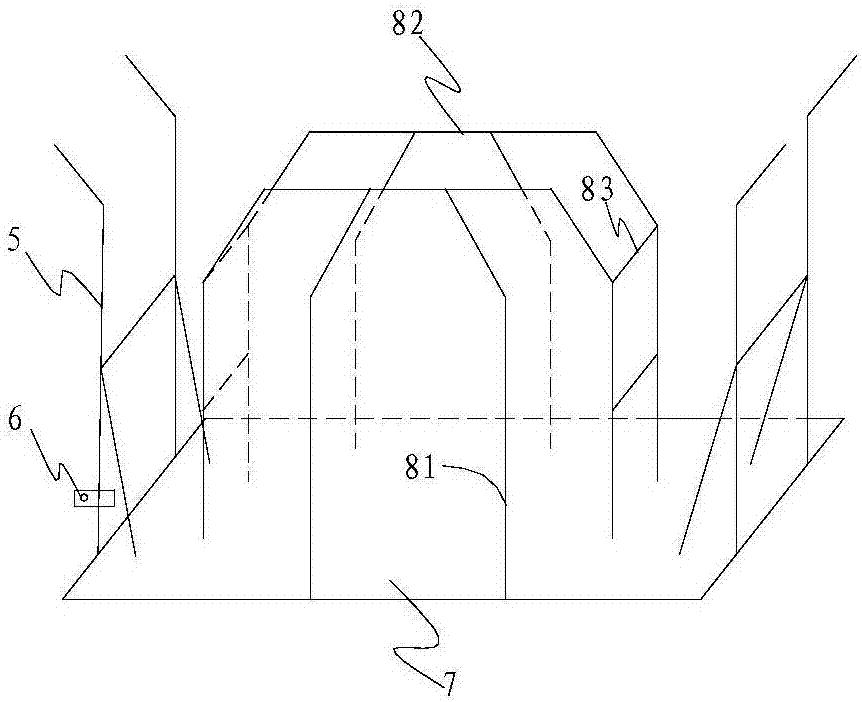

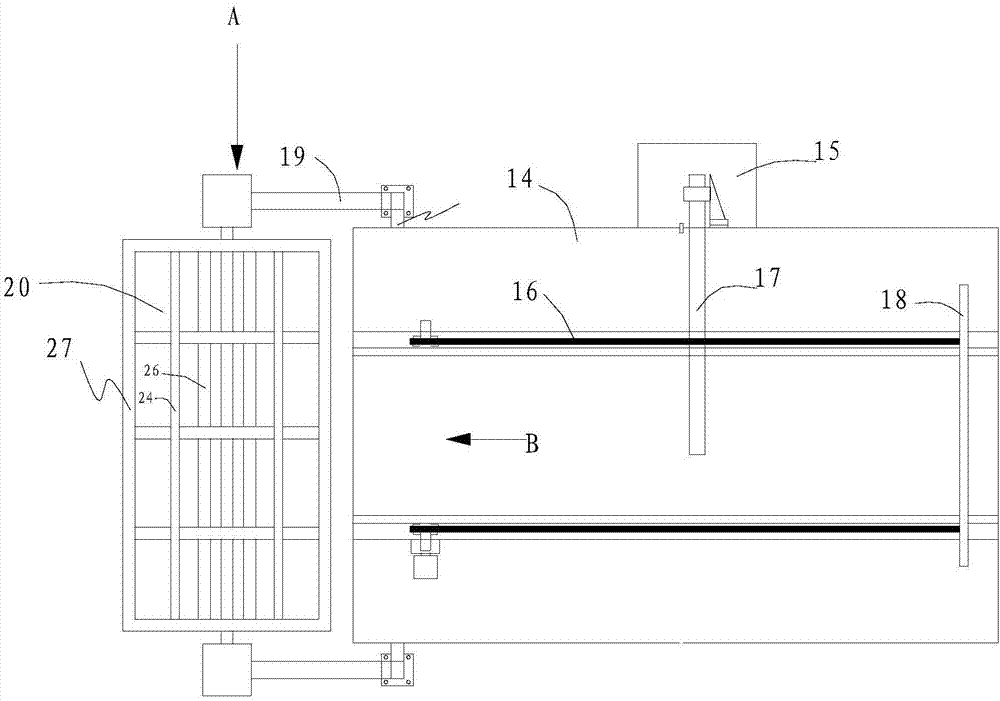

[0069] Such as Figure 1 to Figure 5 As shown, a packaging carton folding and stacking device includes a receiving device, a stacking device and a folding transmission device connecting the receiving device and the stacking device.

[0070] receiving device such as figure 1 and figure 2 As shown, it includes the bottom frame 1, the bottom plate 7 installed above the bottom frame and the support mechanism. The bottom plate and the support mechanism are driven by the turning mechanism to turn over 90° in the vertical plane above the bottom frame. The turning mechanism includes the first rotating shaft 4. The motor 2 and the fixing seat 3, the first rotating shaft is installed on the chassis 1 through the bearing, the fixing seats are arranged as a pair of symmetry, the bottom surface of the bottom plate is fixedly connected with the fixing seat, the first rotating shaft passes through the fixing seat and is connected with the fixed seat The seat is fixedly connected, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com