Propylene, ethylene/1-butene graft copolymer and its reactive extrusion preparation method

A technology of graft copolymer and butene binary copolymer, which is applied in the preparation of ethylene/1-butene graft copolymer and its reaction extrusion, and in the field of propylene, which can solve the problem of inconsistency in the test value of fracture nominal strain impact brittleness temperature Advanced problems, to achieve the effect of performance improvement, high fracture nominal strain, low impact embrittlement temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

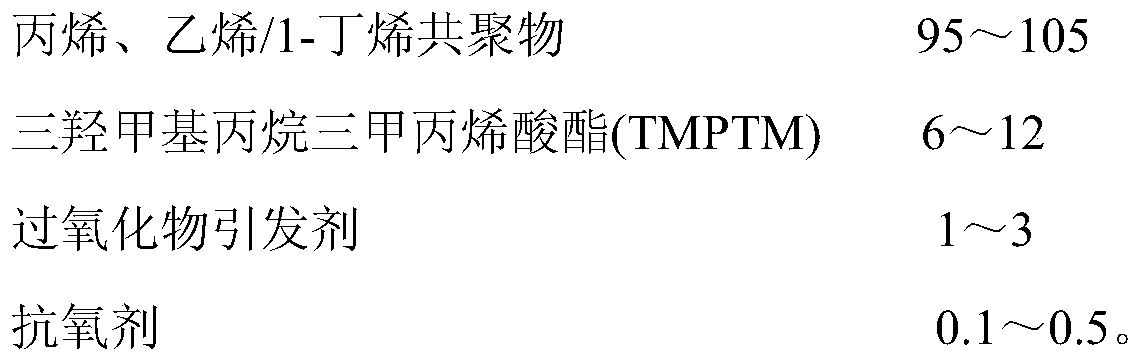

[0022] A kind of propylene, ethylene / 1-butene graft copolymer, it is prepared by the component of following parts by weight:

[0023]

[0024] Reactive extrusion prepares the method for propylene, ethylene / 1-butene graft copolymer, comprises the following steps:

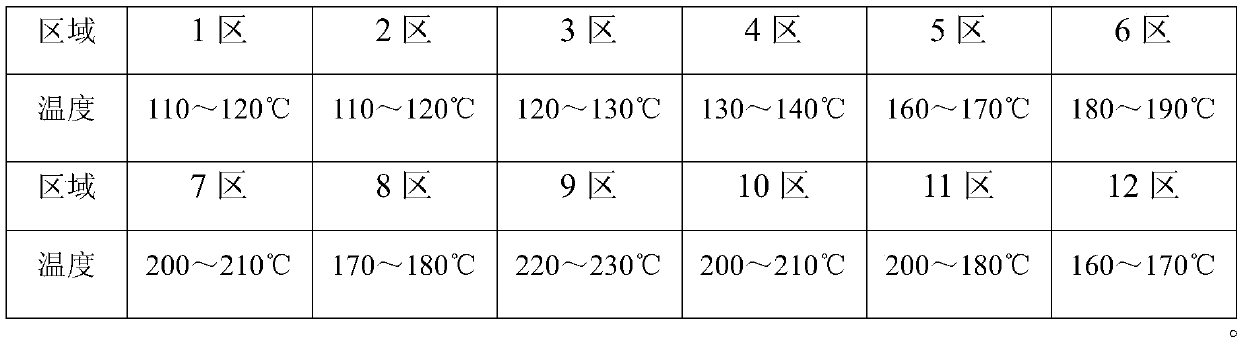

[0025] Add propylene, ethylene / 1-butene into the first hopper of a twin-screw extruder with an aspect ratio (the ratio of the working length of the screw to the diameter of the screw) of 48:1, and add TMPTM, DCP, and antioxidant 1010 into the twin-screw extruder In the second hopper of the extruder, the ratio of the distance between the second hopper and the first hopper to the total length of the screw is 20:48, and the screw speed is 80 rpm, extruding and granulating in the twin-screw extruder; The outlet temperature settings are shown in Table 2.

[0026] Table 2

[0027]

[0028] The properties of propylene, ethylene / 1-butene graft copolymer and ungrafted copolymer prepared in this embodiment are shown in...

Embodiment 2

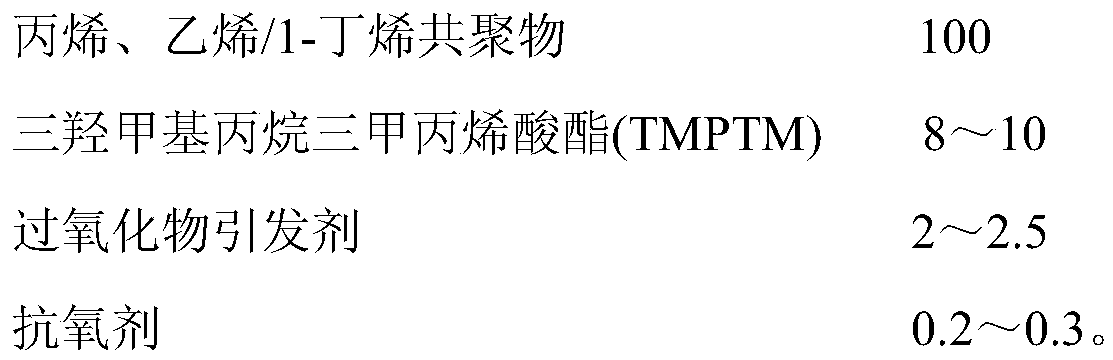

[0032] A kind of propylene, ethylene / 1-butene graft copolymer, it is prepared by the component of following parts by weight:

[0033]

[0034] According to the production method of Example 1, propylene and ethylene / 1-butene graft copolymer were obtained, and the properties are shown in Table 4.

[0035] Table 4

[0036] Test items Detection method graft copolymer Nominal Strain at Break% GB / T1040.2-2006 525 Impact embrittlement temperature ℃ GB / T5470-2008 -98

Embodiment 3

[0038] A kind of propylene, ethylene / 1-butene graft copolymer, it is prepared by the component of following parts by weight:

[0039]

[0040] According to the production method of Example 1, propylene and ethylene / 1-butene graft copolymer were obtained, and the properties are shown in Table 5.

[0041] table 5

[0042] Test items Detection method graft copolymer Nominal Strain at Break% GB / T1040.2-2006 516 Impact embrittlement temperature ℃ GB / T5470-2008 -96

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com