Mountain tunnel construction risk assessment method based on computer aided engineering (CAE) finite element model

A technology for risk assessment and tunnel construction, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as difficult tunnel accurate and effective risk assessment, unable to meet the overall requirements of mountain tunnel risk assessment, etc., to achieve The effect of saving recording work, overcoming fuzzy judgment, and facilitating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] A finite element model-based risk assessment method for mountain tunnel construction mainly includes the following steps:

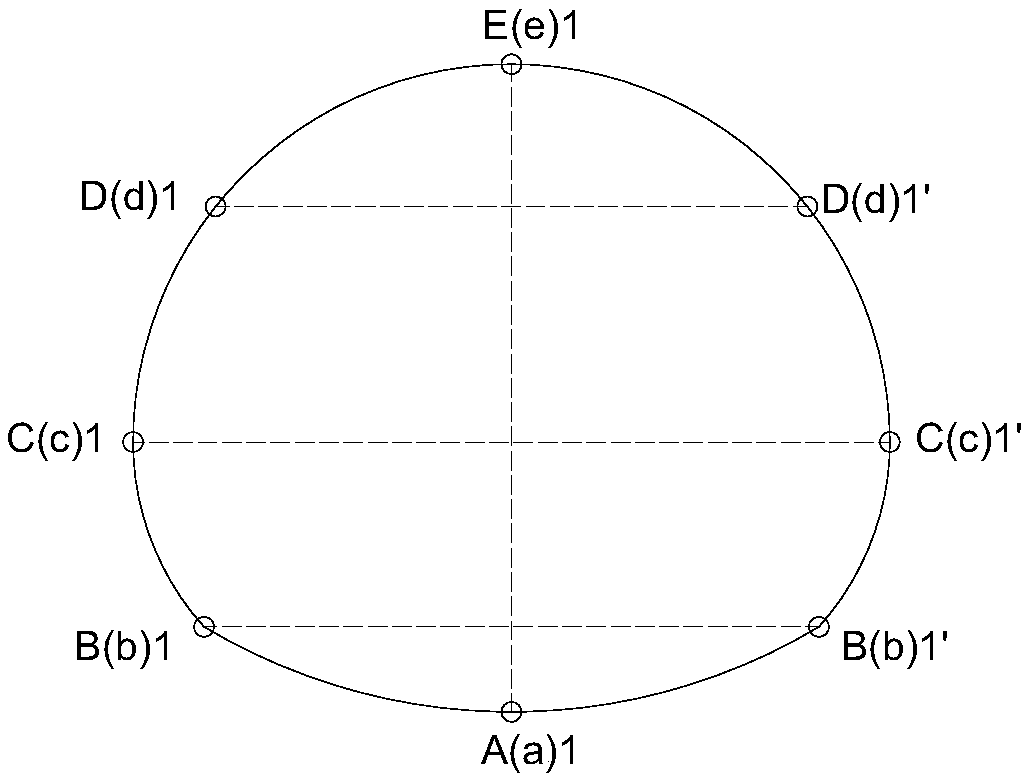

[0027] Step 1: With the help of CAE finite element software, establish a finite element model of the mountain tunnel, which can reflect its three-dimensional characteristics, and draw a three-dimensional model diagram (such as image 3 shown), where the initial parameters included in the model are: tunnel section form and size x, surrounding rock grade y, lining type z; x can be edited directly, while y and z need to be edited by changing material properties; building After the model is completed, by inputting the above-mentioned initial parameters, the force change during the tunnel construction process can be simulated;

[0028] Step 2: Use the mesh division finite element method to calculate the stress and deformation characteristics of the tunnel, and obtain the displacement and stress of the tunnel vault, side wall, inverted arch and other par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com