Leather cutting equipment for bag manufacturing

A leather cutting technology, which is applied in the field of leather cutting equipment for luggage manufacturing, can solve the problems of easy folding, low thickness, and the quality of finished luggage does not meet the national standard.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

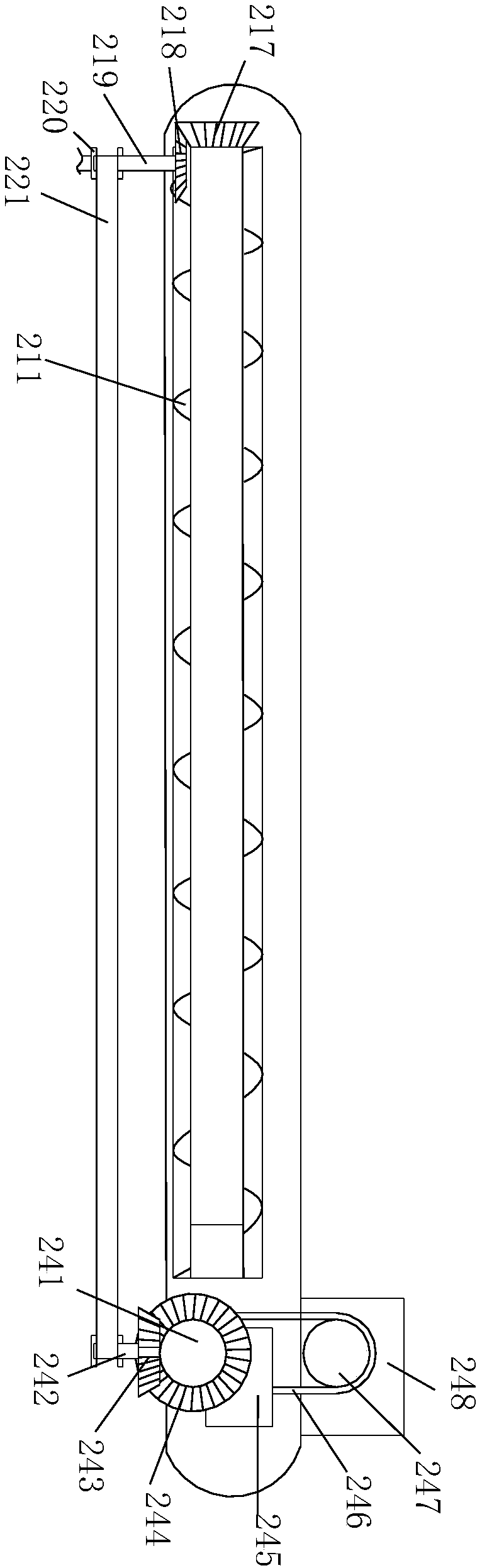

[0022] see Figure 1-Figure 5 , the present invention provides a kind of leather cutting equipment for bag manufacturing, its structure includes supporting column 1, paving and stretching mechanism 2, operating platform 3, first limit rod 4, knife rest 5, second limit rod 6, Paving inlet 7, operation button 8, cooling outlet 9, body 10, operation panel 11, the top of the body 10 is fixed with an operation platform 3, and the two sides of the operation platform 3 are equipped with a paving stretching mechanism 2. One side of the paving stretching mechanism 2 is provided with a paving inlet 7, and a heat dissipation port 9 is opened on the body 10 below the paving inlet 7, and an operating Panel 11, the operation panel 11 is equipped with more than two operation buttons 8, the first limit rod 4 and the second limit rod 6 are installed on both sides of the paving inlet 7, the described The first stop bar 4 and the second stop bar 6 are vertically welded on the operating platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com