Horizontal bagging machine

A bagging machine, horizontal technology, used in packaging and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0122] The present invention will be further described below in conjunction with accompanying drawing.

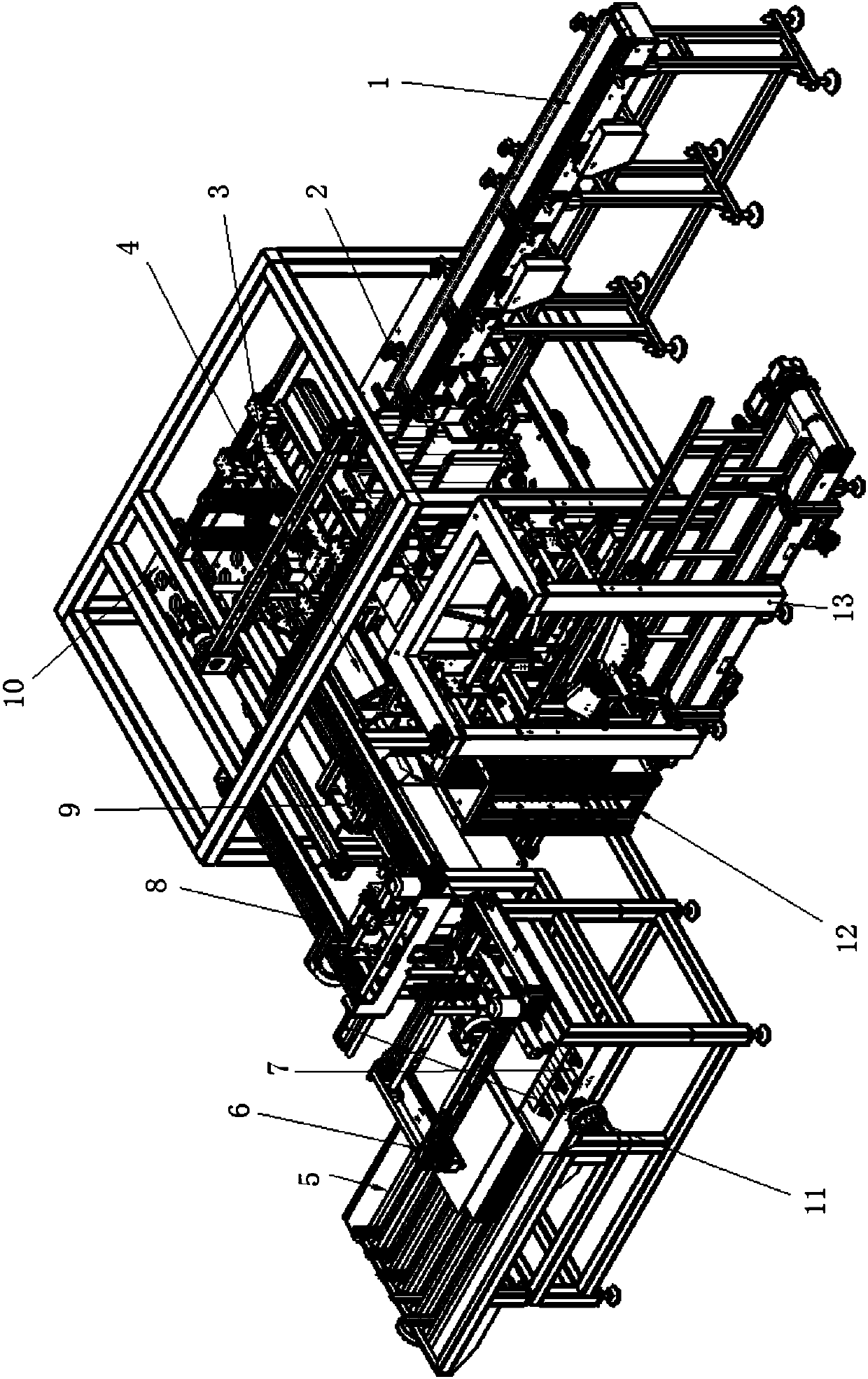

[0123] see figure 1 , the horizontal bagging machine of the present invention comprises a feeding device 1, an alignment device 2, an upper transfer device 3, a side pressure turning device 4, a bag bin device 5, a horizontal bag taking device 6, a bag feeding device 7, Bag taking and bagging device 8 , bag mouth guiding and control device 9 , material pushing and bagging device 10 , whole bag transfer device 11 , whole bag turning device 12 and bag mouth sorting and controlling device 13 .

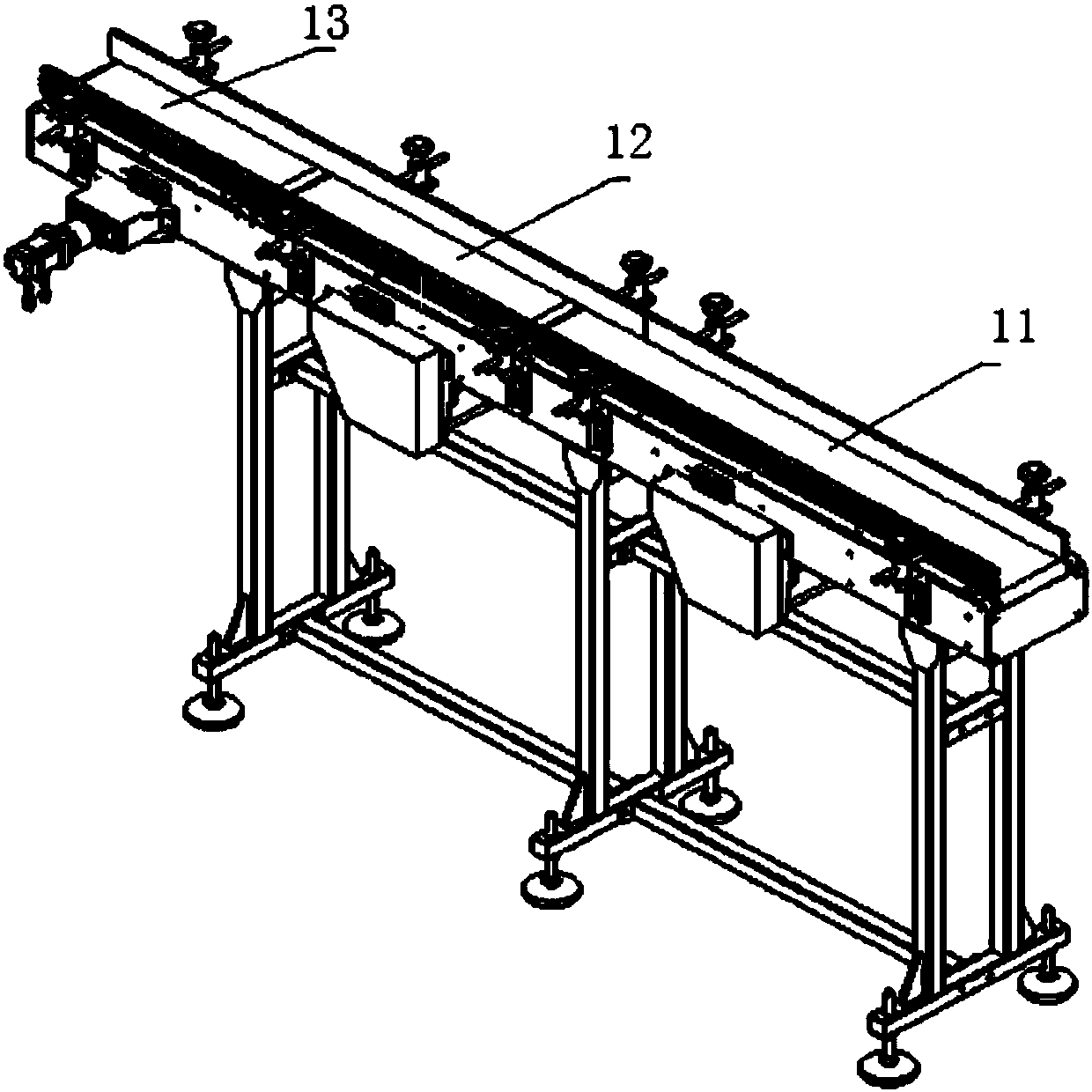

[0124] The feeding device 1 is used for stacking unit bags and transporting them backwards. Specifically, see figure 2 , The feeding device 1 includes: a feed line 11 that receives and transmits unit bags from the front-end conveying line; receives the unit bags from the feed line 11, and stacks each unit bag; stacking line 12; The final unit bags are delivered to the servo feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com