Combined type car lifting auxiliary tool and car descending method based on tool

An auxiliary tooling and combined technology, which is applied in the direction of the lateral relative movement between the chassis and the bogie, etc., can solve the problems of affecting the docking, asynchronous docking, shaking instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be described in further detail below in conjunction with the accompanying drawings.

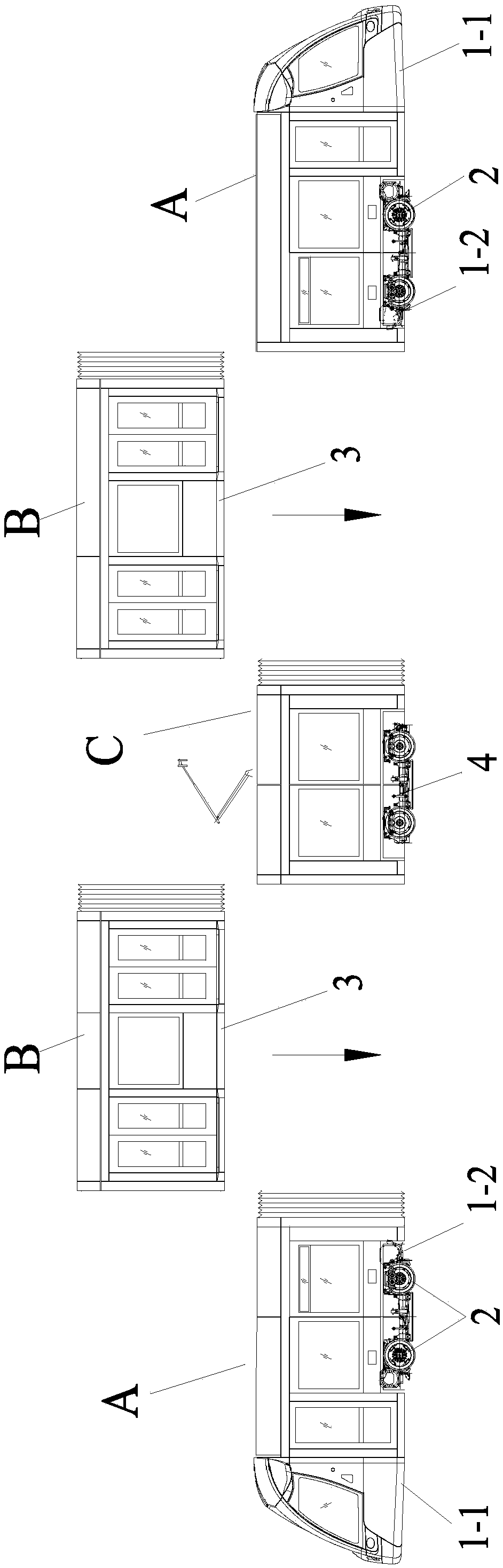

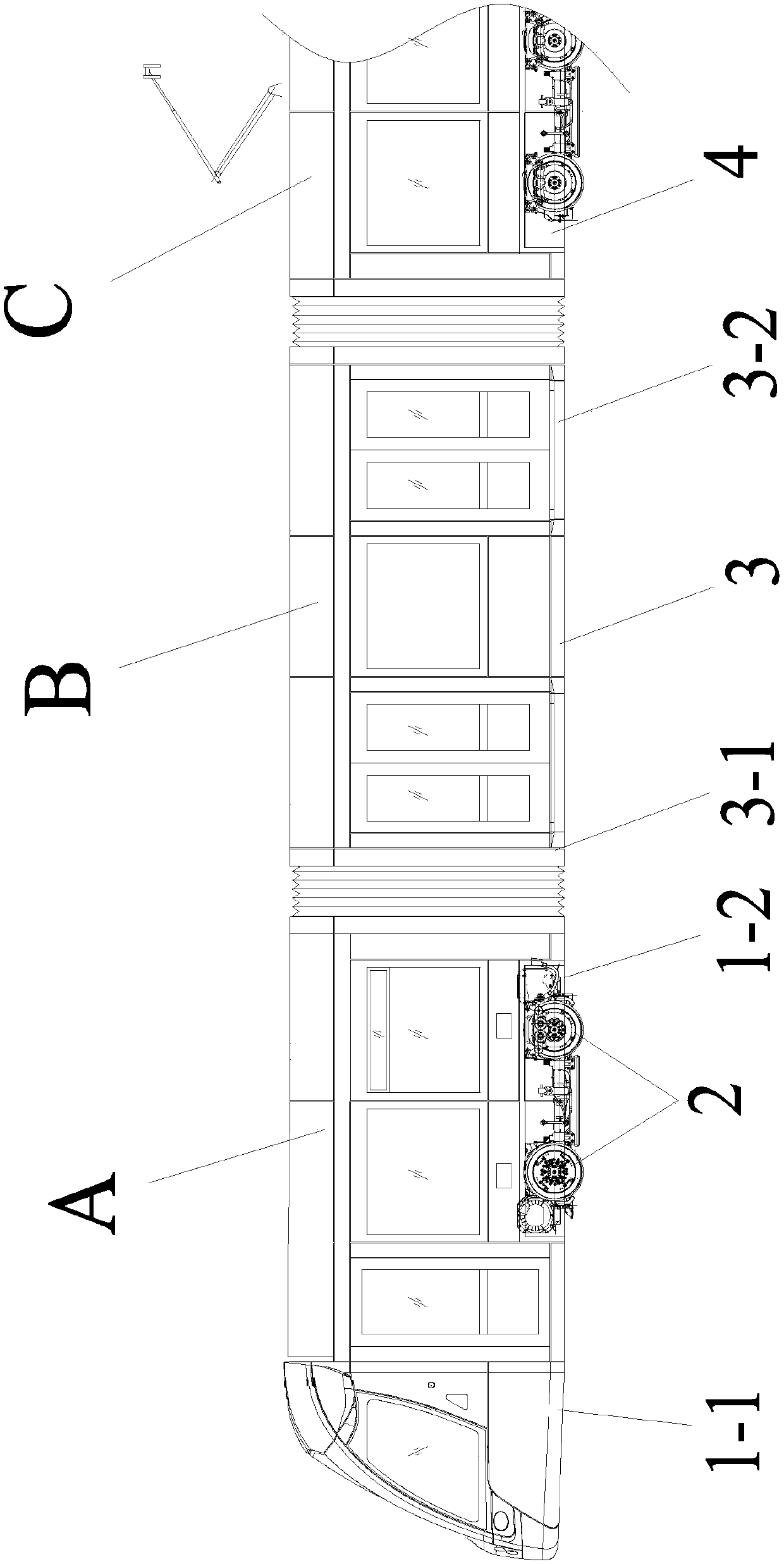

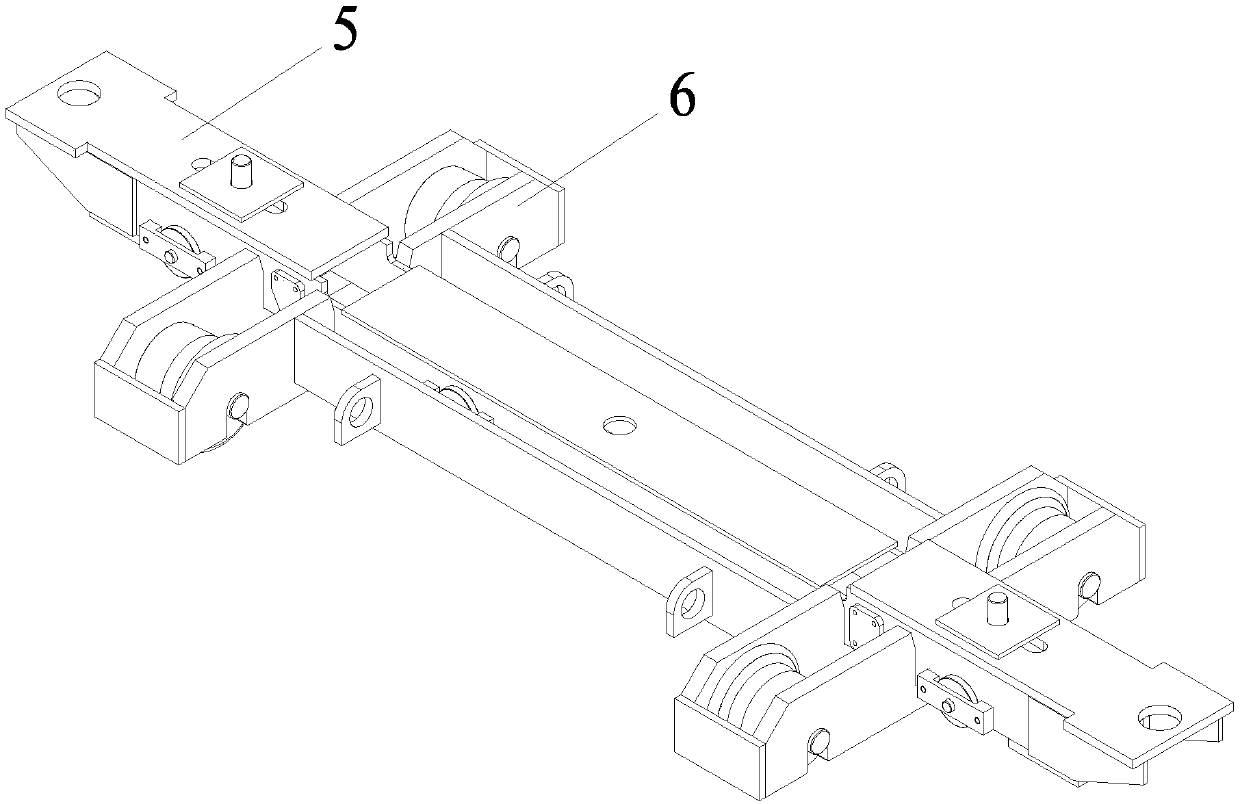

[0070] Such as Figure 3 to Figure 10 As shown, the combined vehicle auxiliary tooling of the present invention includes an auxiliary beam 5 for the underframe of the vehicle and an auxiliary lifting trolley 6 at one end of the driver's cab. One end of the driver's cab assists in lifting the trolley 6 and includes two lift trolley pairs of mechanisms and a channel steel crossbeam 6-1, and two lift trolleys pair of mechanisms are symmetrically fixed to the two ends of the channel steel crossbeam 6-1. Two lifting lugs 6-1-1 are respectively provided on the two outer sidewalls of the channel steel beam 6-1. Each lifting trolley wheel pair mechanism all comprises rectangular wheel pair mounting frame 6-2 and two transport track wheels 6-3, and two transport track wheels 6-3 are arranged symmetrically along the long side midline of rectangle, and respectively wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com