Tool for machining rocker arm fork entry

A rocker fork and tooling technology, which is applied to workpiece clamping devices, manufacturing tools, etc., can solve the problems of long time occupied by assembling fixtures, processing deviation from scribing, unstable quality, etc., and achieves convenient implementation, simple mechanism, and operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

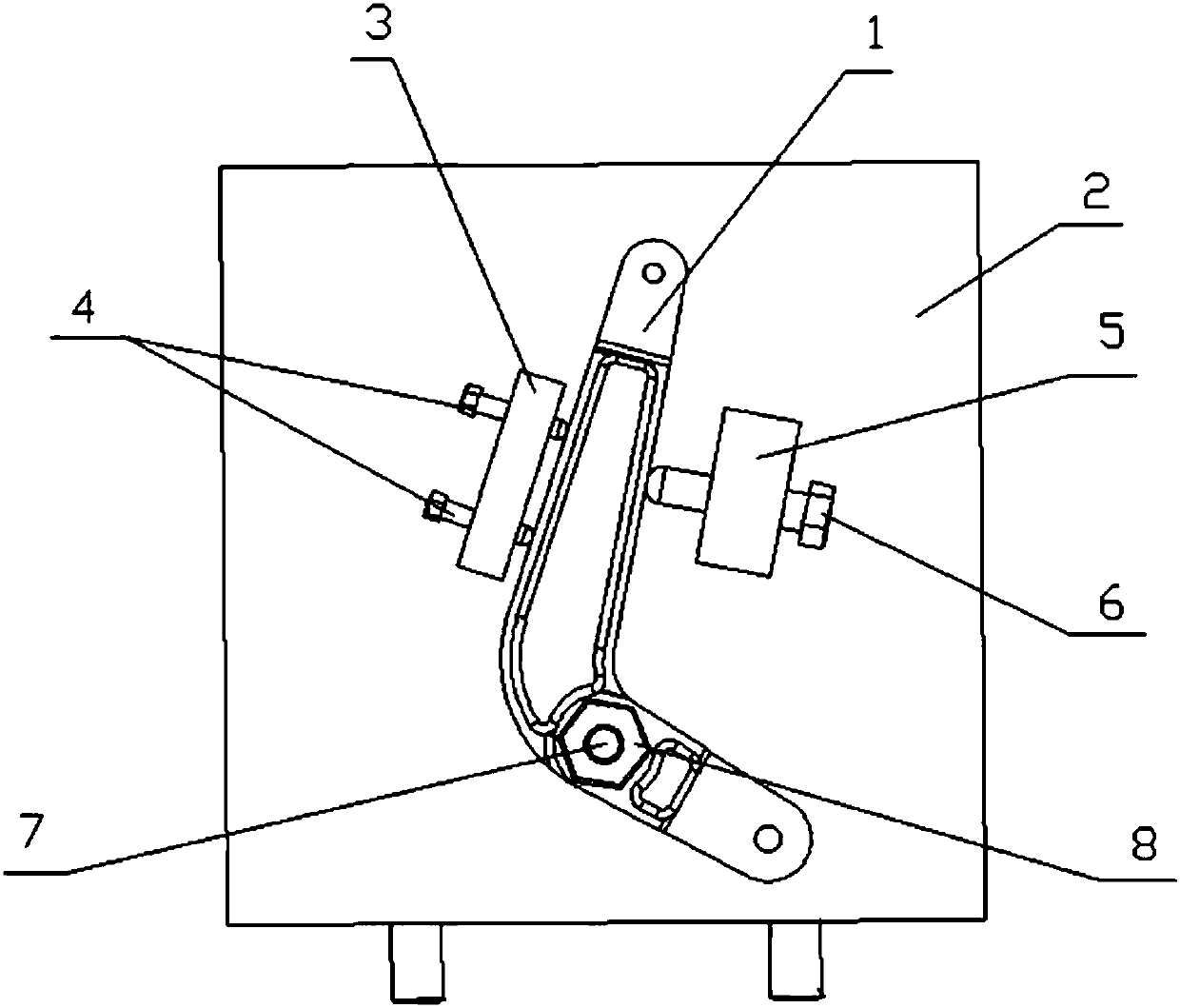

[0015] Provide a kind of tooling for processing the yoke of the rocker arm, the rocker arm part has a shaft hole; the tooling includes a mounting plate 2, a positioning block 3, a positioning adjustment screw 4, a fixing block 5, a fixing screw 6, and a positioning shaft 7 and fastening nut 8; the positioning block 3 has two threaded holes 10; the fixed block 5 has a threaded hole 13; the positioning adjustment screw 4 has two, and respectively with the positioning block The two threaded holes are matched; the fixing screw is matched with the threaded hole of the fixed block; the positioning shaft 7 is fixed on the mounting plate 2, and the positioning shaft 7 has an external thread 11 on the top, and the bottom is a polished rod, which is connected with the fastening nut 8 matches with the external thread of the positioning shaft. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com