An anti-drip high and low pressure combined nozzle and high pressure cleaning equipment

A technology of high-pressure nozzles and low-pressure nozzles, which is applied in the field of anti-drip high-low pressure combined nozzles and high-pressure cleaning equipment, which can solve problems such as insufficient outlet pressure and affect the normal use of equipment, and achieve the effect of avoiding dripping water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

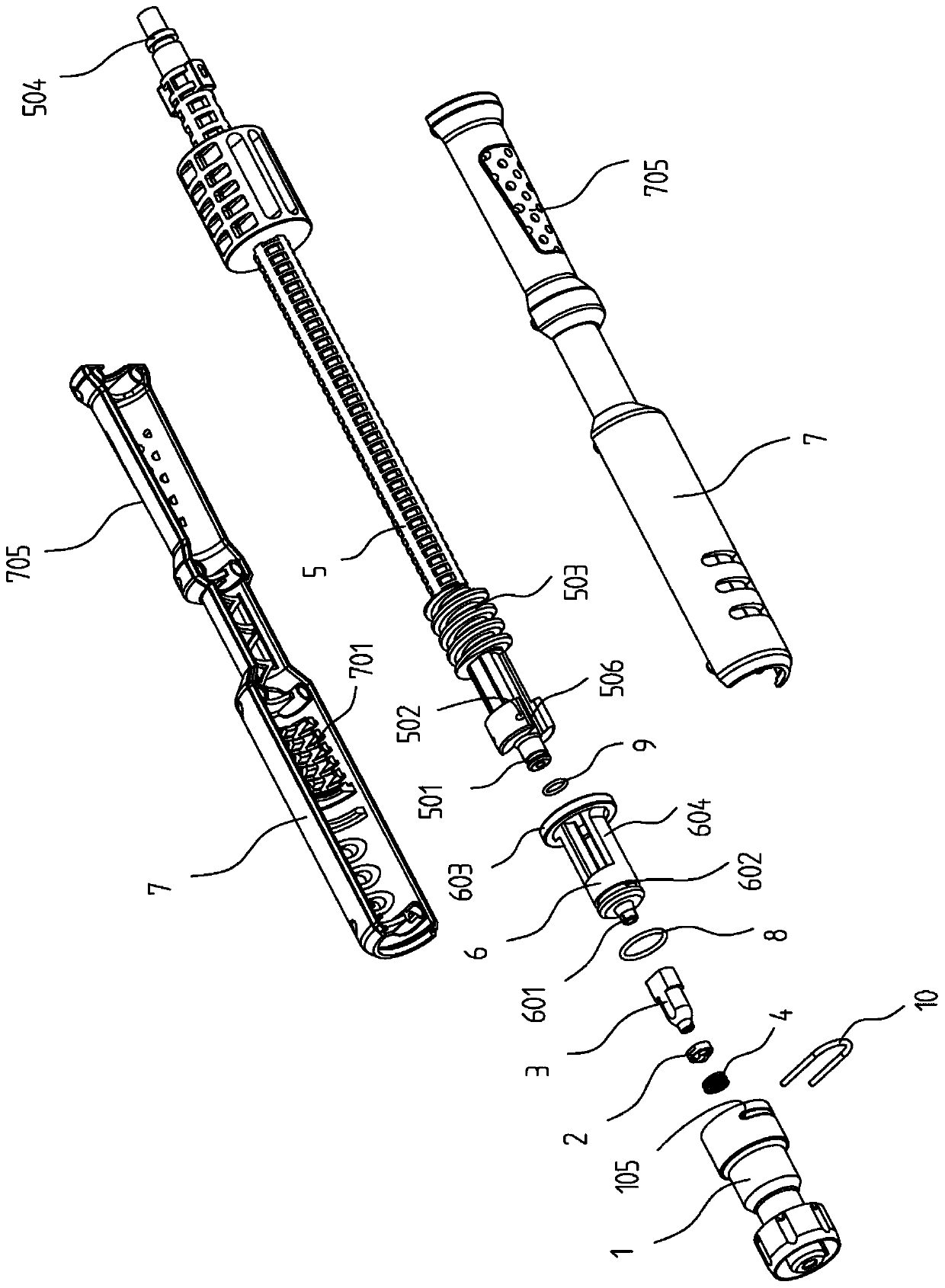

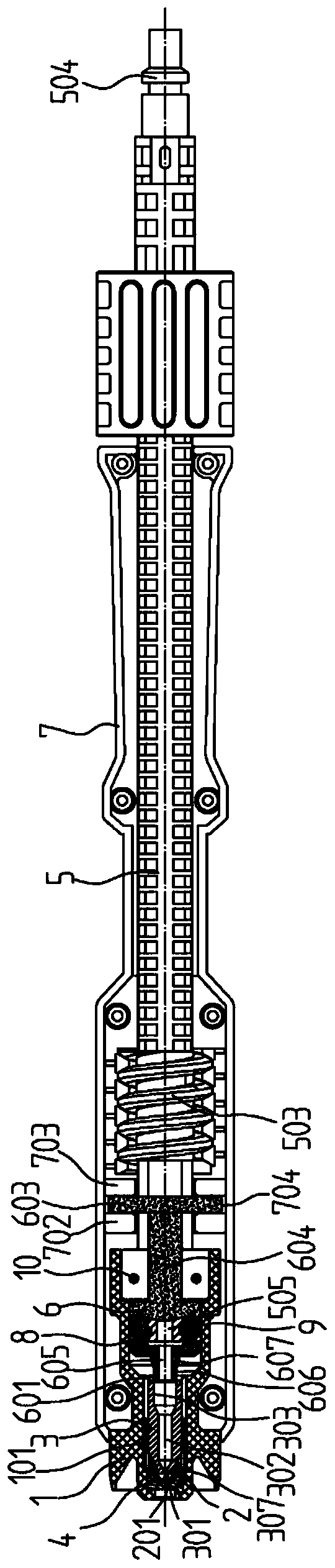

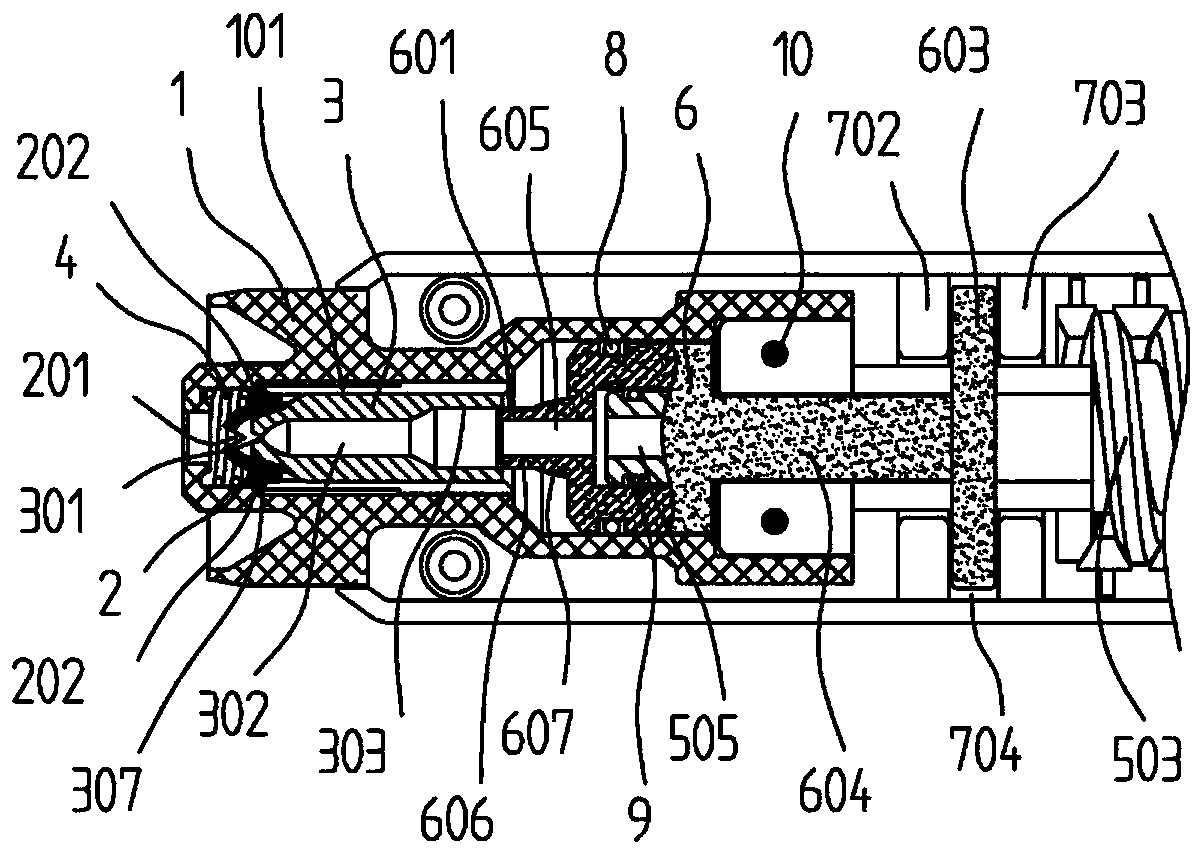

[0053] Such as Figures 1 to 7 As shown, a high-pressure cleaning device can prevent dripping at the outlet. The way to achieve this goal is to use an anti-drip high and low pressure combined nozzle. Valve 6, which has a water hole 605, head shell 1, which has a cavity through its front and rear ends to accommodate the high-pressure nozzle 3 and the slide valve 6; low-pressure nozzle 2, which has a center facing all The main water outlet 201 of the central spray channel 302 , at least one auxiliary water outlet 202 arranged around the main water outlet 201 , and the spring 4 . The slide valve 6 is slidably arranged behind the high-pressure nozzle 3; the outer wall of the slide valve 6 forms a sliding seal with the wall of the cavity, and the outer wall of the high-pressure nozzle 3 and the wall of the cavity A bypass path 101 is formed between the walls of the cavity, and the bypass path 101 can communicate with or be closed to the central nozzle 302 when the sliding valve 6 ...

Embodiment 2

[0068] Such as Figure 16 As shown, the difference from Embodiment 1 is that in this embodiment, as another typical linear adjustment structure, the discharge groove 601 extends along a helix, and the central axis of the helix is parallel to the outer cylindrical surface 606. central axis. In addition to Embodiment 1 and this embodiment, the discharge groove 601 can also adopt other structures, such as oblique, but due to the consideration of manufacturing cost and difficulty, the discharge in Embodiment 1 and this embodiment is given priority. Structure of groove 601.

[0069] The present invention discloses a high-pressure cleaning equipment using combined nozzles, but other working devices except the nozzles have been disclosed in the prior art. The present invention only improves the nozzles, so the disclosure of the technical solution is comprehensive ground and clearly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com