Multi-field real-time monitoring and servo pressurizing bottom friction testing system for large-size rock-soil body

A real-time monitoring and testing system technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., to achieve the effect of expanding the application range, overcoming insufficient lighting conditions, and enriching experimental data and information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

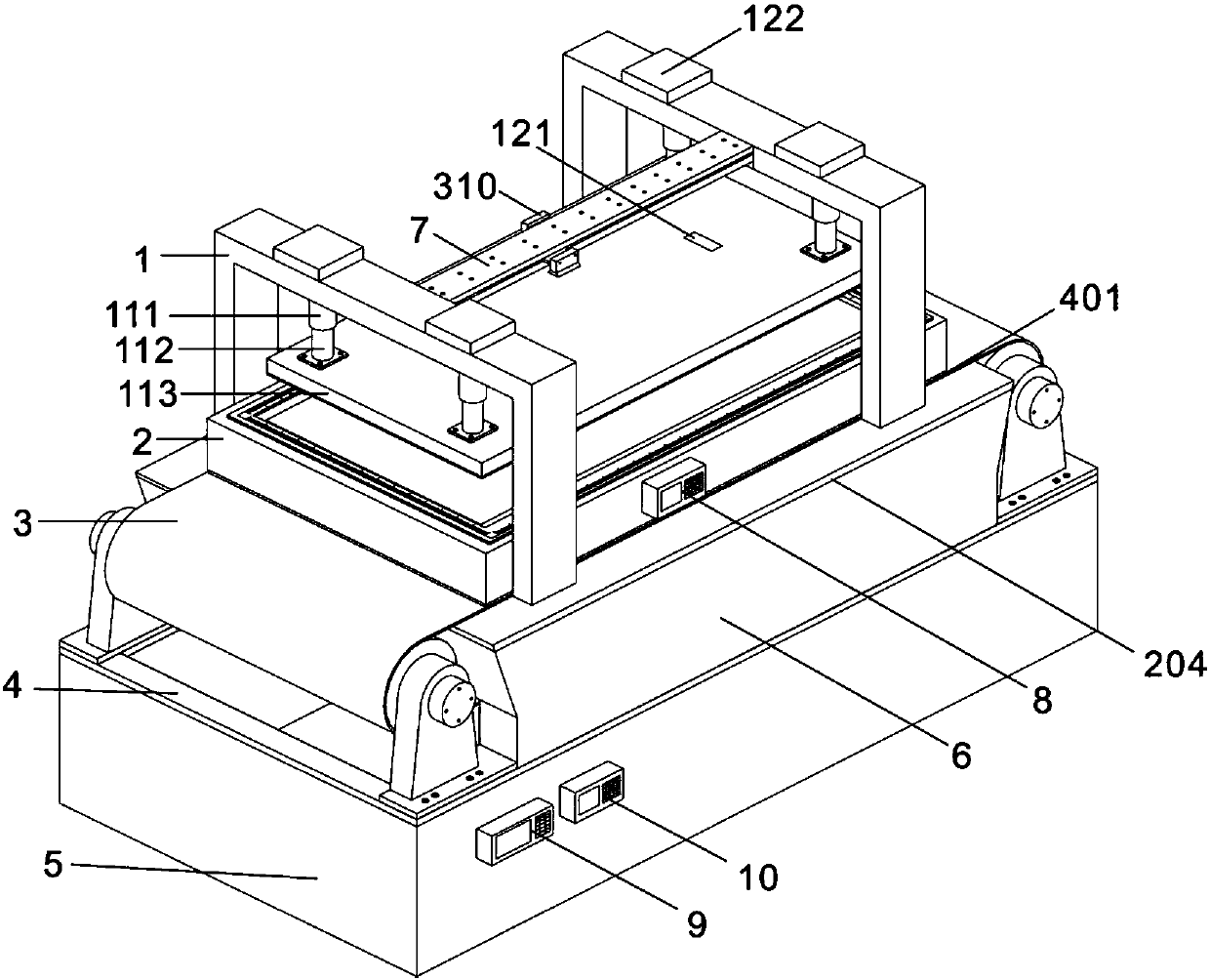

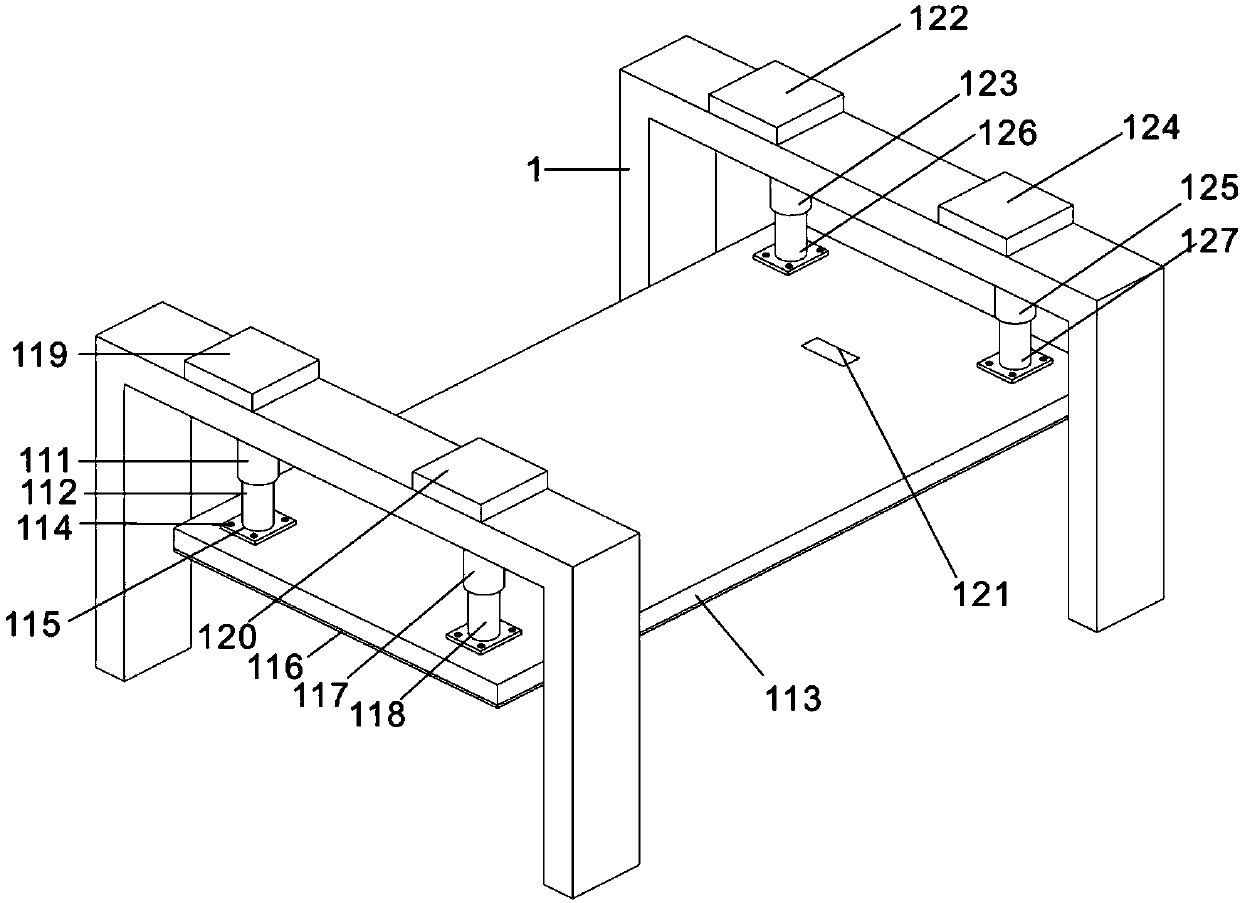

[0043] Example: such as figure 1 As shown, the multi-field real-time monitoring servo pressurized bottom friction test system for large-scale rock and soil mass in this embodiment includes a frequency conversion continuously variable speed conveyor belt drive system, a model vertical uniform force loading servo system, a model friction force measurement system, and a high-speed Camera image acquisition and resolution system.

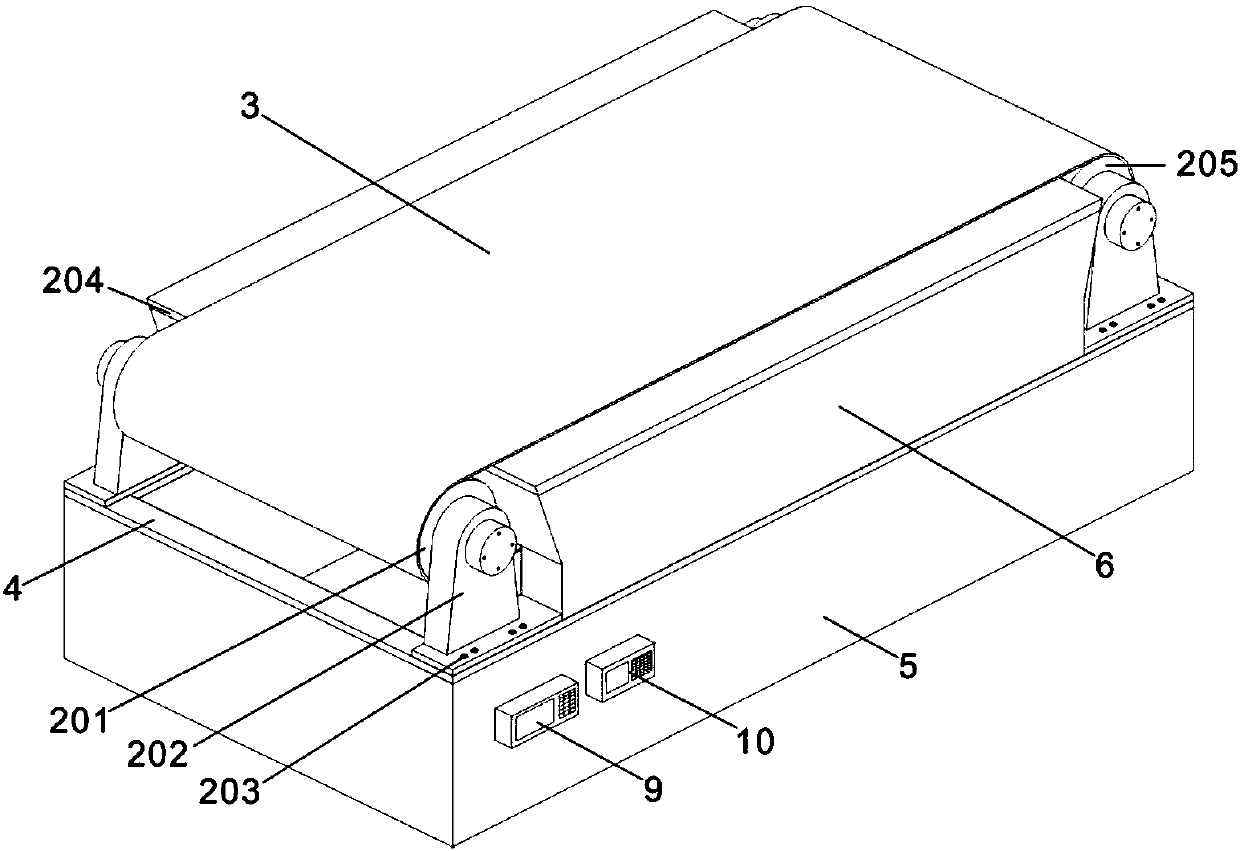

[0044] Such as figure 2 and 6 As shown, the above-mentioned variable frequency continuously variable speed conveyor belt drive system is arranged at the lower part of the model. The frequency variable continuously variable speed conveyor belt drive system has a conveyor belt speed monitor 10 for detecting and controlling the speed of the conveyor belt 3. The conveyor belt speed monitor 10 passes through the line Connected in series with the frequency converter 15 and the AC motor 14, the conveyor belt speed monitor 10 can control the speed of the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com