Scissors-fork type lifting stage

A stage and scissor technology, applied in the field of scissor lift stage, can solve the problems of unstable lift stage, low safety factor, and unstable motor speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order for those skilled in the art to better understand the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and the following embodiments.

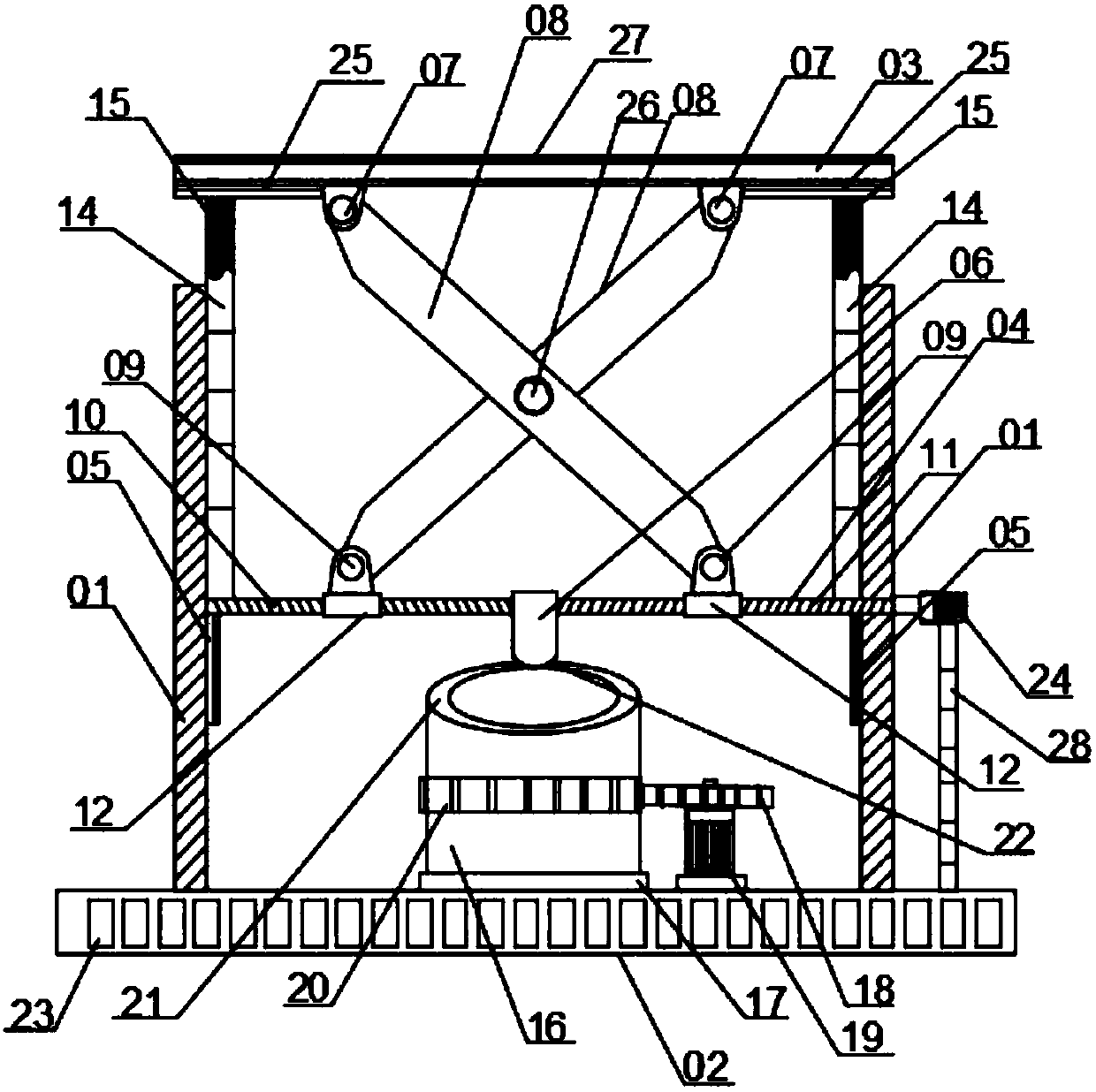

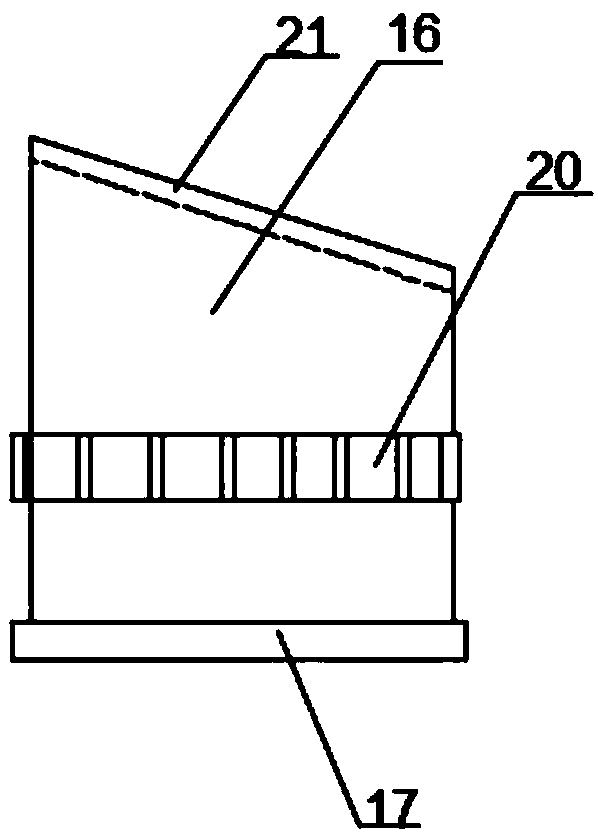

[0024] Please refer to Figure 1 to Figure 2 As shown, this embodiment provides a scissor lift stage, including a support frame 01, a base 02 for fixing the support frame 01, and a stage board 03 installed on the upper end of the support frame 01, and a stage board 03 is arranged between the support frames 01. The supporting screws 04 are parallel to each other, and the inner side of the supporting frame 01 is provided with a vertical guide rail 05. The left and right ends of the supporting screw 04 are embedded in the vertical guide rail 05 and are slidably connected with the vertical guide rail 05. A scissor lift mechanism that drives the stage board 03 to move vertically.

[0025]Specifically, the scissor-type lifting mechanism includes an upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com