Piston type multi-jaw robot end effector

An end effector and robot technology, applied in the field of robots, can solve problems such as insufficient grasping accuracy, low grasping strength, and poor synchronization of grasping actions, and achieve the effects of maintaining accuracy, large transmission torque, and small motion damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

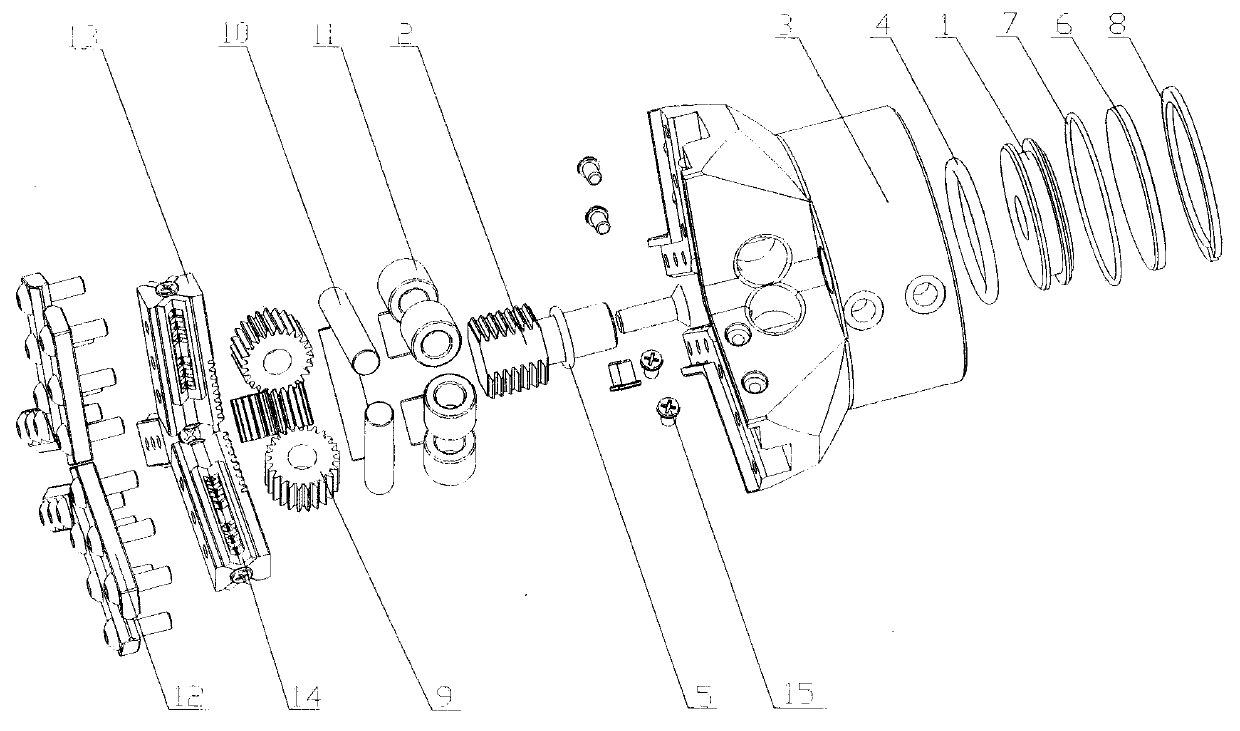

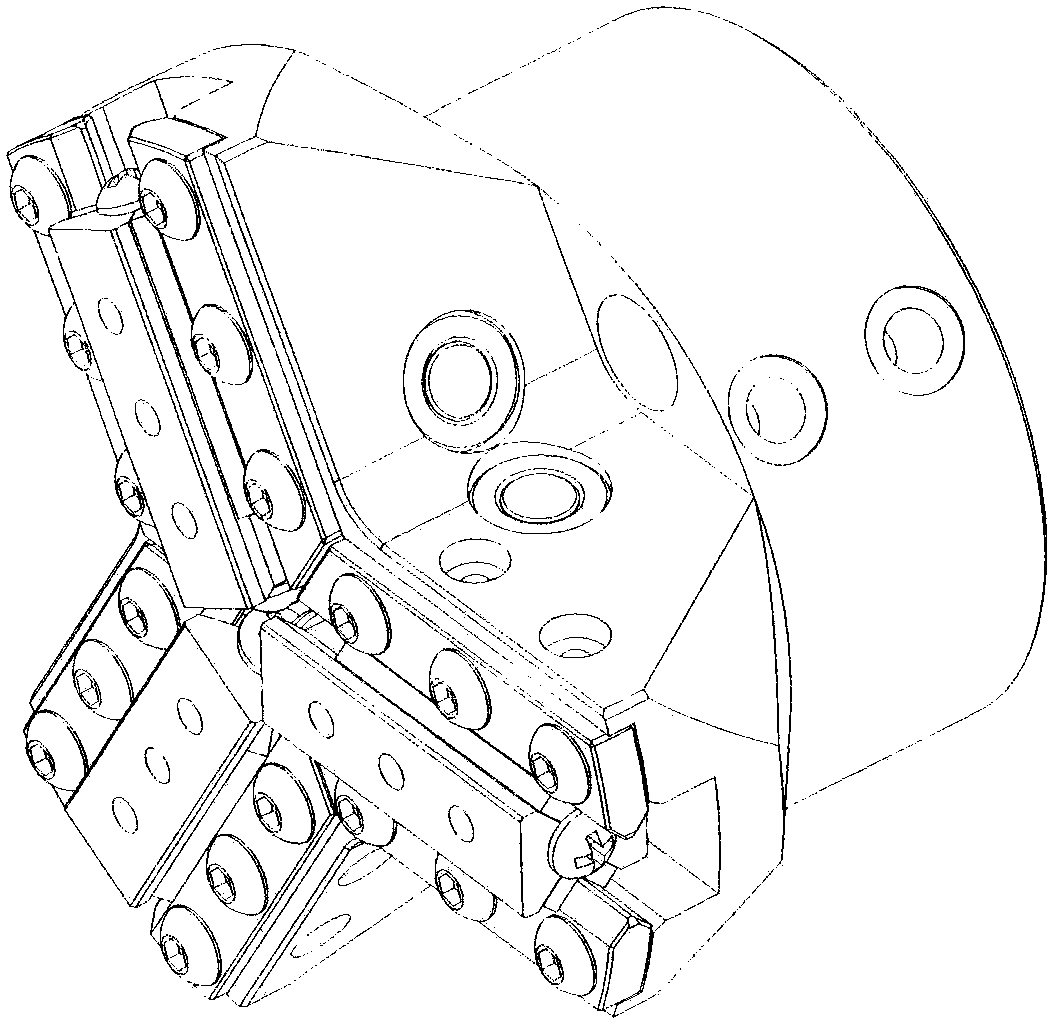

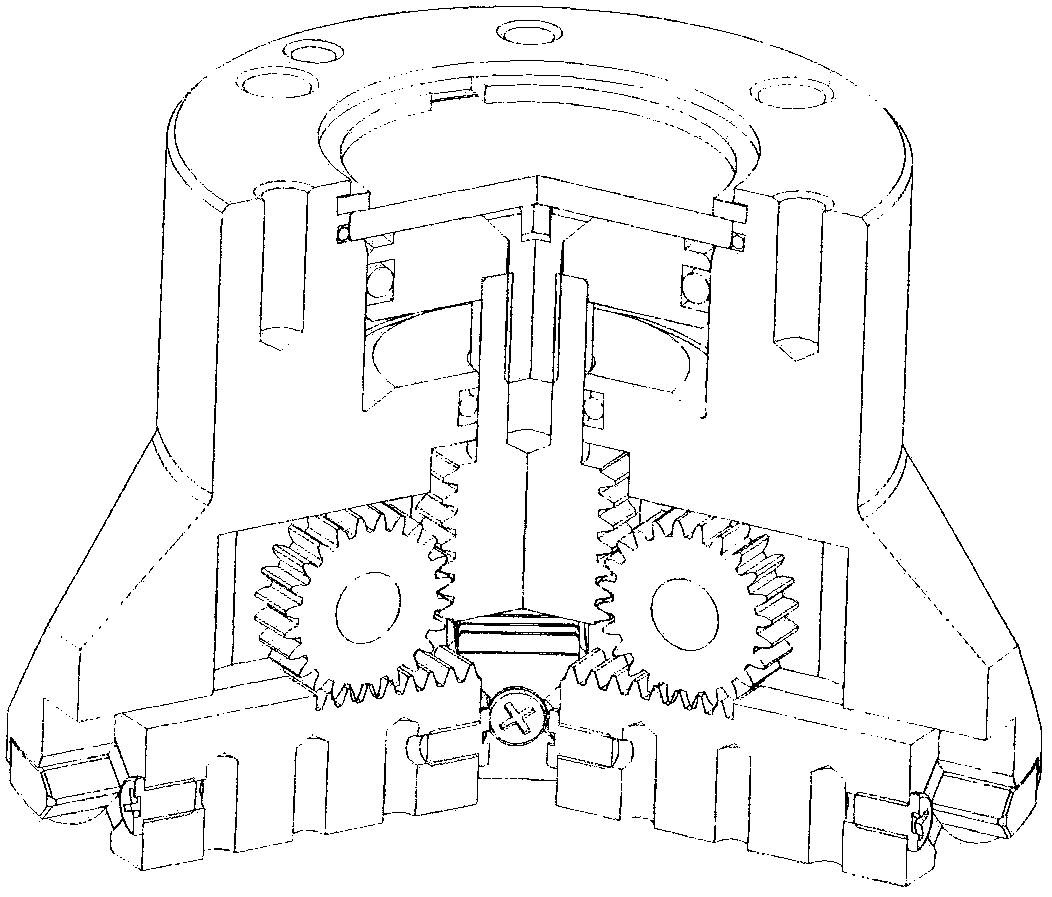

[0023] The number of faces of the gear rod 2 in the end effector of the piston-type multi-claw robot is 4, such as Figure 5-8 As shown, the number of gears 9 and gear shafts 10 is four, and the number of groups of slide rails 12 is four groups. The input and output fluid through the two holes on the housing 3 drives the piston 1 to move, and the piston 1 drives it to be fixed. The connected four-sided gear rod 2 moves linearly; the four gears 9 are respectively installed on the four gear shafts 10, and the four gear shafts 10 are supported inside the housing 3 by a pair of bearings 11, and four groups of gear shafts are installed on the end surface of the housing 3 Slide rails 12, each set of slide rails 12 is equipped with a rack-type slider module, the rack-type slider module is composed of a rack-type slider 13 and a pair of cylindrical roller moving guide rails 14, each gear 9 All mesh with the gear bar 2 and its corresponding rack-type slider 13; the linear motion of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com