High/low layered soil loosening process with uniform fertilization function

A functional and uniform technology, applied in the direction of agricultural machinery and tools, agriculture, shovel, etc., can solve the problems of easily damaged equipment, fertilization efficiency, insufficient process optimization, poor soil loosening effect, etc. Optimized, good soil loosening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

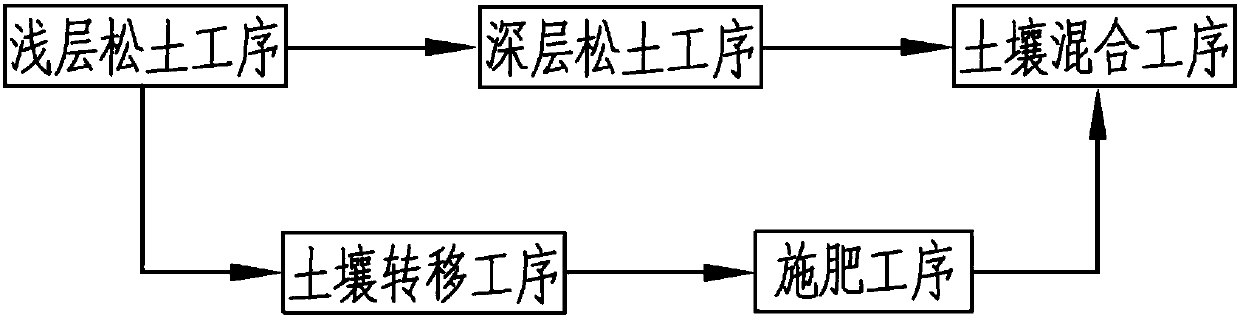

[0060] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 Shown, a kind of high and low stratified soil loosening process with uniform fertilization function, comprises the following production steps:

[0061] Step 1, the shallow soil loosening process, the first loose soil device 3 located at the shallow soil loosening station is driven by the tractor 1 to perform loose soil operation on the shallow soil;

[0062] Step 2, soil transfer process, the soil transfer device 4 located behind the shallow soil loosening station is driven by the tractor 1 to load the soil loosened by the first soil loosening device 3 and transport it back to the fertilization station;

[0063] Step 3, the fertilization process, the fertilization device 5 located at the fertilization station spreads the fast fertilizer into the loose shallow soil during the transmission process;

[0064] Step 4, the deep soil loosenin...

Embodiment 2

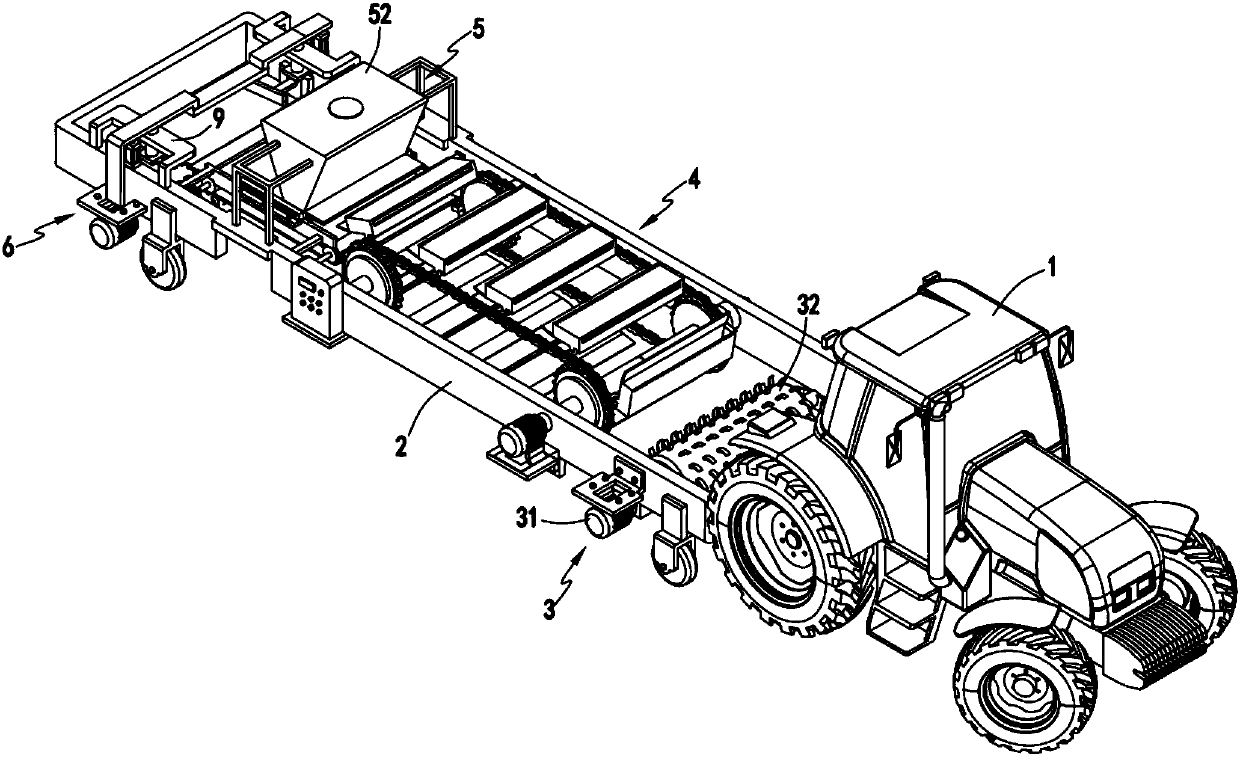

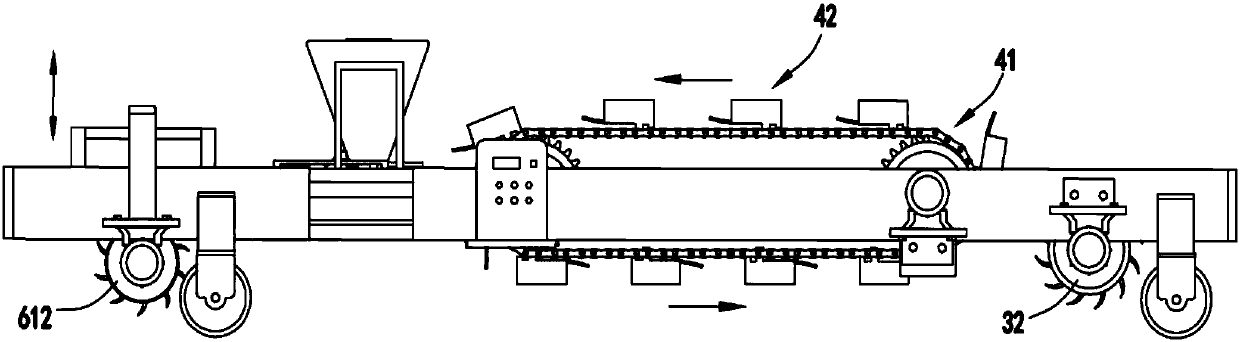

[0074] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, a kind of high and low stratified soil loosening equipment with uniform fertilization function includes a tractor 1 and a walking carrier 2 driven by the tractor 1, and the walking carrier 2 is sequentially provided with upper and lower parts for the land from front to back. The first soil loosening device 3 that loosens the surface soil, the soil transfer device 4 that is used to transfer the loose upper surface soil backward, the fertilizing device 5 that is used to fertilize the upper layer soil in the transfer process, and is used to fertilize the deep layer The second loosening device 6 for loosening the soil;

[0075] The soil transfer device 4 includes a turning mechanism 41, several soil moving units 42 driven by the turning mechanism 41 and a transmission mechanism 43 arranged at the rear end of the turning mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com