De-energized line-loss-free high-voltage injection molding module

A technology of de-powering and injection molding, which is applied in the field of LED modules for advertising signs, can solve problems such as poor contact, cumbersome wiring, and small number of cascades, and achieve the effects of small line loss, large number of cascades, and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the drawings and embodiments, but this should not limit the protection scope of the present invention.

[0017] For the convenience of description and understanding of the technical solution of the present invention, the orientation words used in the following description are all subject to the orientation shown in the drawings.

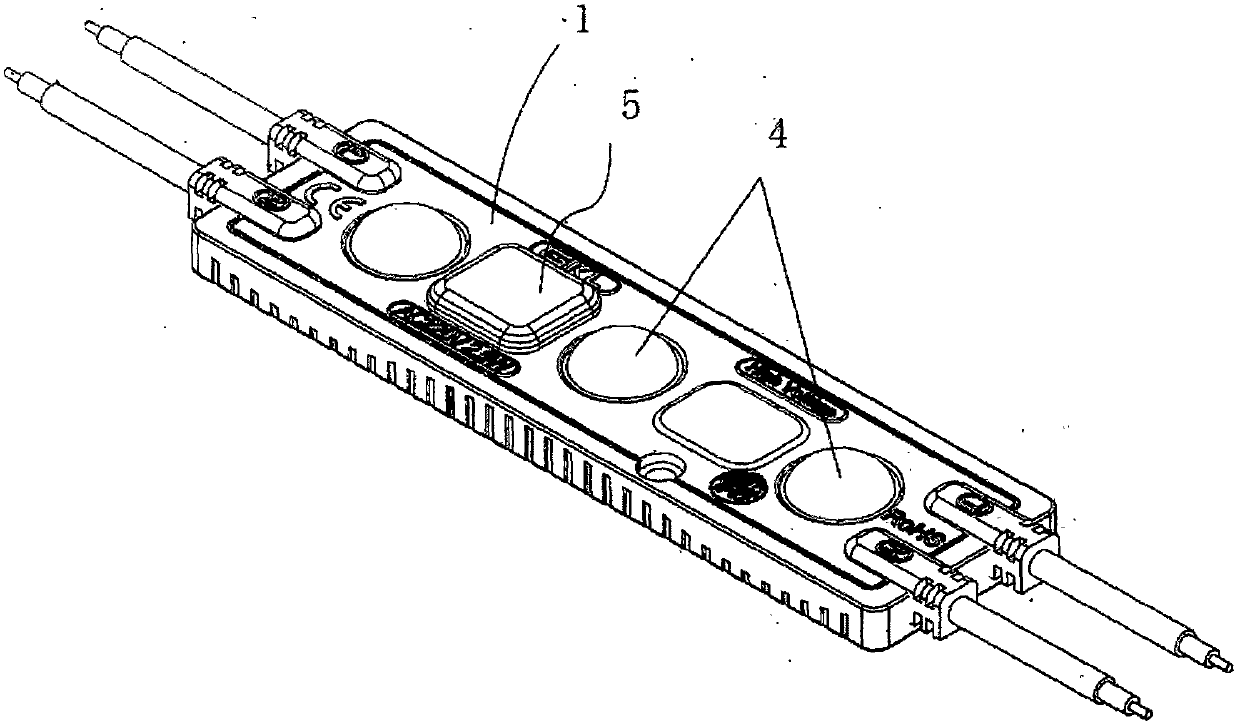

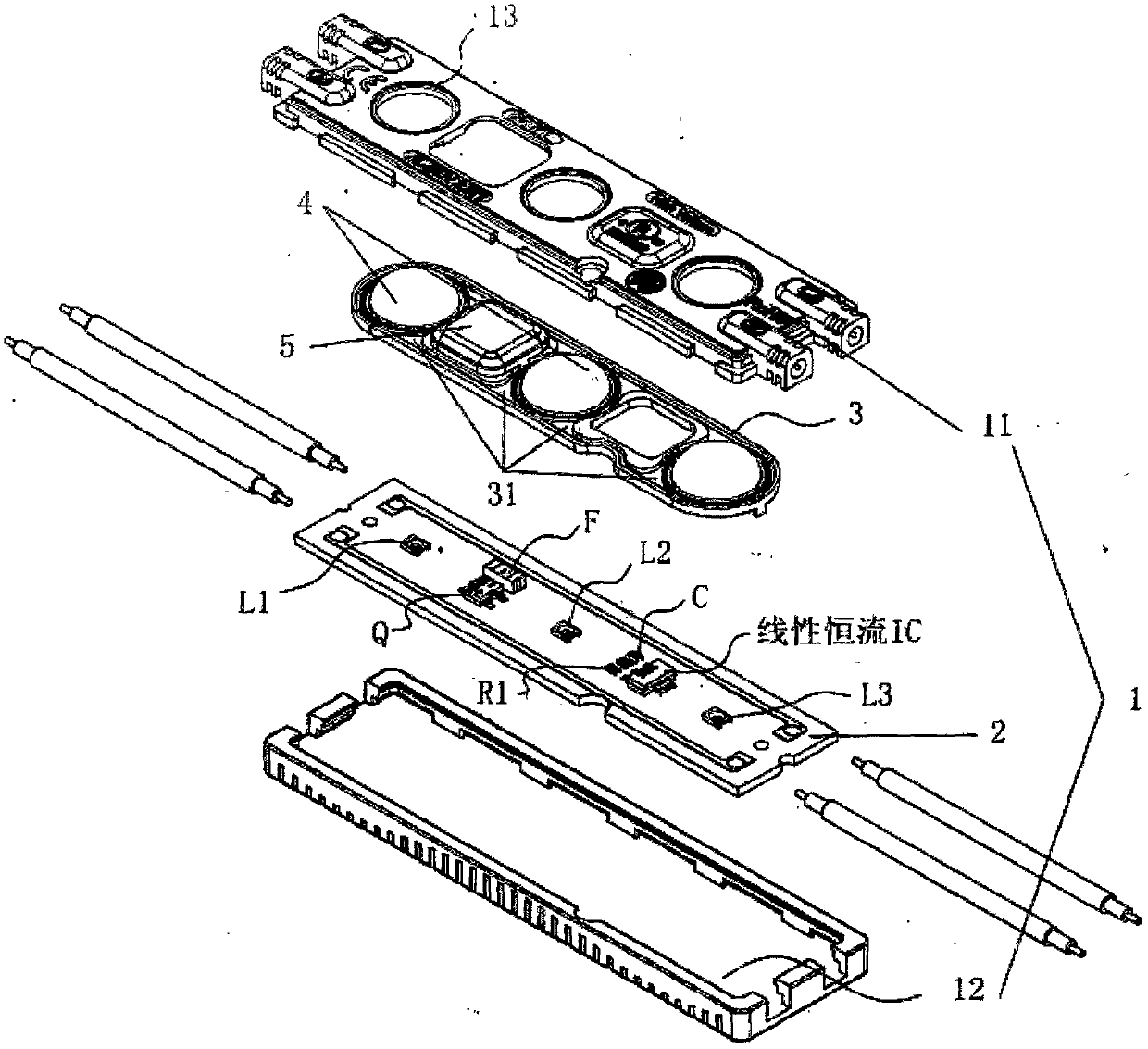

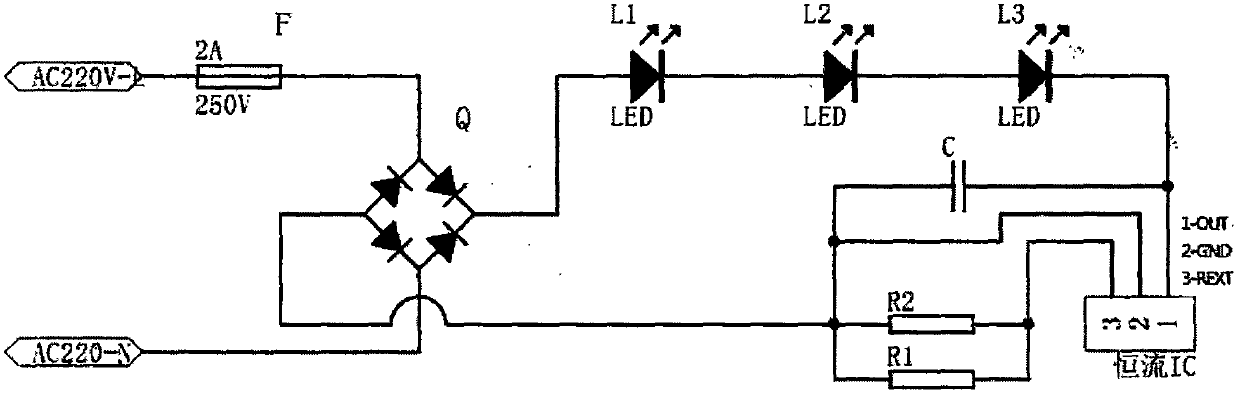

[0018] Such as Figure 1 to Figure 3 As shown, a de-power lossless high-pressure injection molding module of the present invention includes a housing 1, a PCB board 2 located in the housing 1, and a circuit located on the PCB board 2, and the circuit includes a fuse F. Rectifier bridge Q, LED lamp group, first resistor R1, second resistor R2 and linear constant current IC, the LED lamp group includes several high-voltage LED lamp beads connected in series, the AC end of the rectifier bridge Q is connected to the AC Power connection, one DC end of the rectifier bridge Q ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com