Anchored type arch bridge suspender system combining flexible inhaul cable with rigid pull rod

A technology of flexible cables and suspenders, which is applied in the field of arch bridge components, can solve problems such as horizontal stress, centering error, new suspenders, and limited conduit expansion, and achieve the effect of structural solution and convenient maintenance and inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

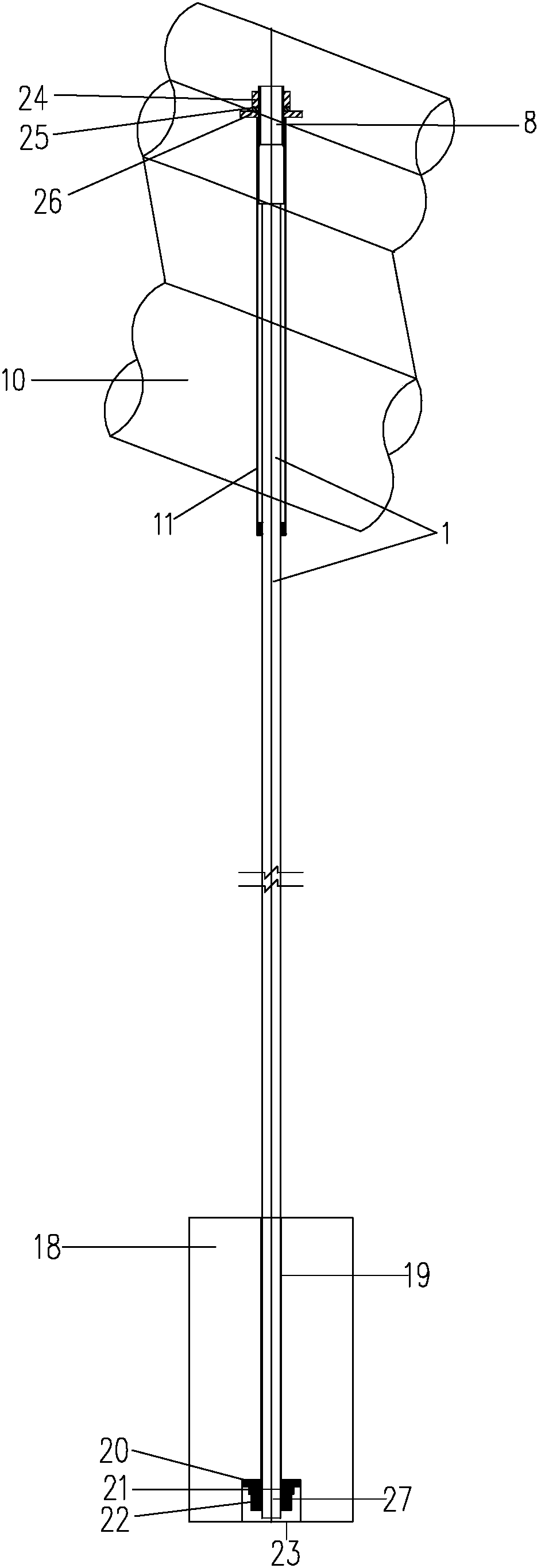

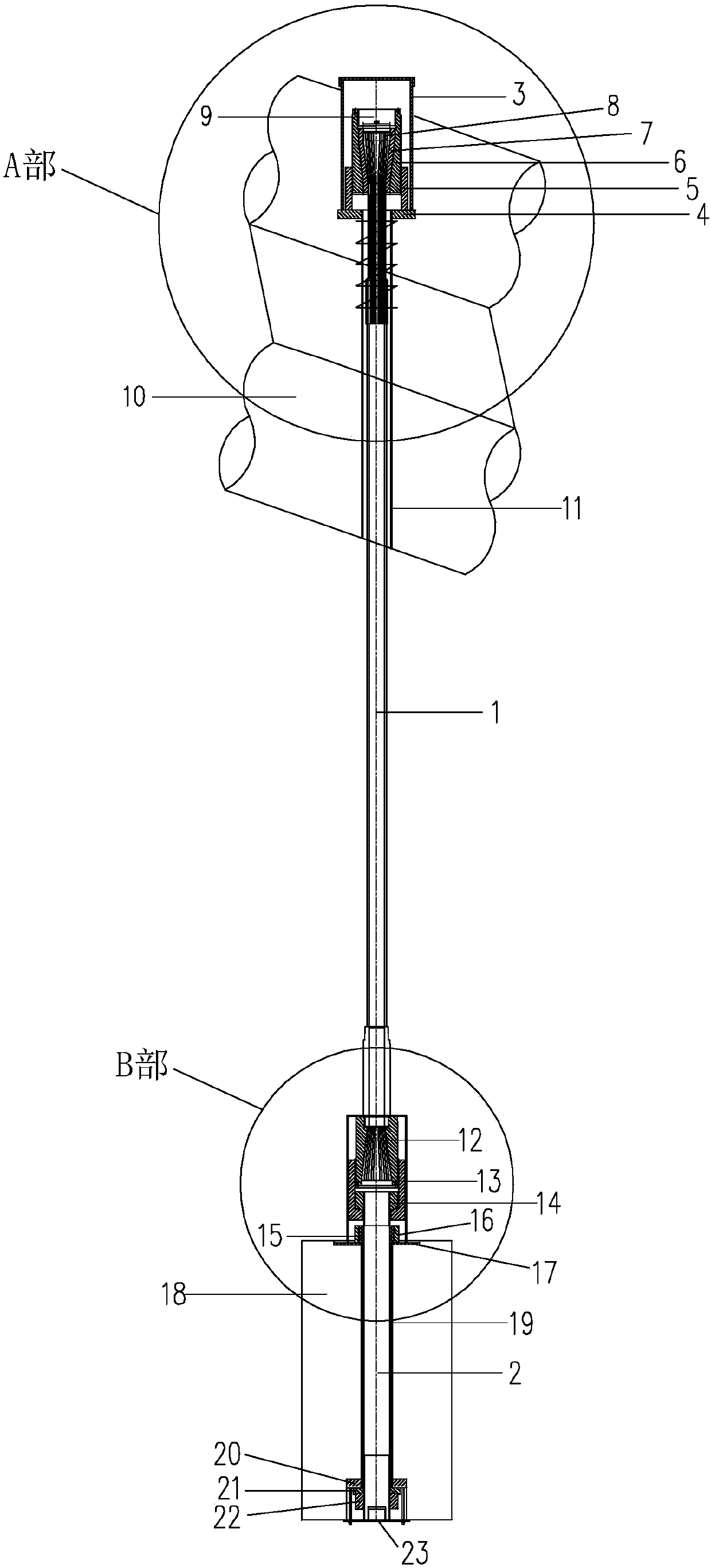

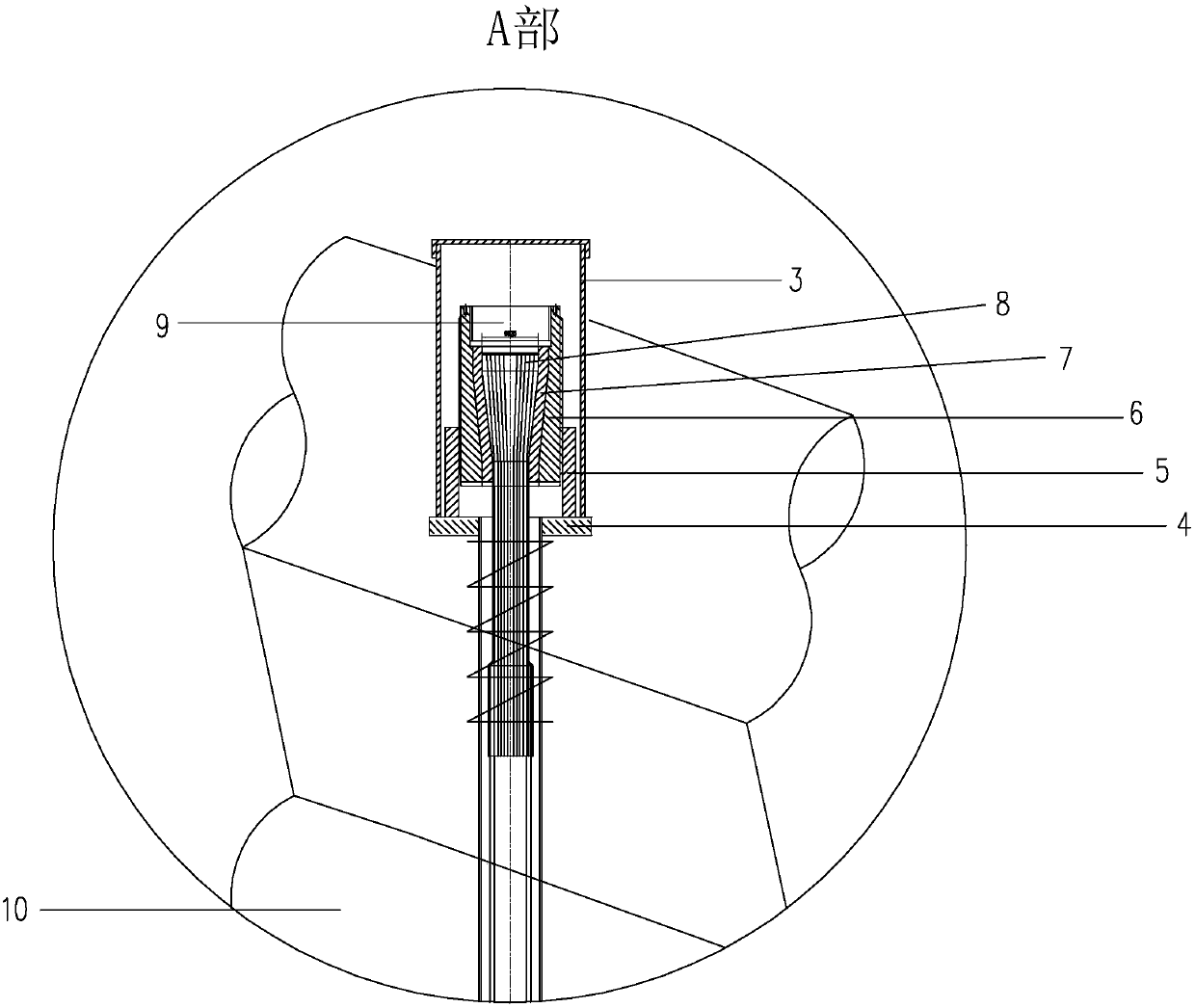

[0051] The anchored arch bridge suspender system of flexible stay cable of the present invention combined with rigid pull rod is as Figure 2 to Figure 8 As shown, it includes an upper anchor head, an upper anchor member, a suspender cable body 1, a steel tie rod 2, a lower anchor head and a lower anchor member. In the hole, an arch rib pre-embedded pipe 11 is pre-buried in the arch rib 10, and the upper end of the suspender cable body 1 is the upper anchor head. The suspender cable body 1 is anchored in the arch rib, and the steel tie rod 2 is a rigid tie rod. The lower end of the suspender cable body 1 and the upper end of the steel tie rod 2 are connected by a cable rod connecting member, and the lower anchor member is located in the anchor hole of the arch bridge beam 18 , the crossbeam 18 is pre-embedded with a crossbeam pre-embedded pipe 19, the lower end of the steel tie rod 2 is the lower anchor head, the lower anchor head passes through the crossbeam pre-embedded pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com