Tool for lifting big pieces for double travelling cranes and manufacturing method thereof

A technology of crane and tooling, applied in the field of machinery, can solve the problems that the lifting capacity of a single crane cannot meet the requirements, the lifting capacity of a single crane is insufficient, and the weight of a single crane is insufficient, and the structure is simple and easy to operate , the effect of meeting the needs of lifting large pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

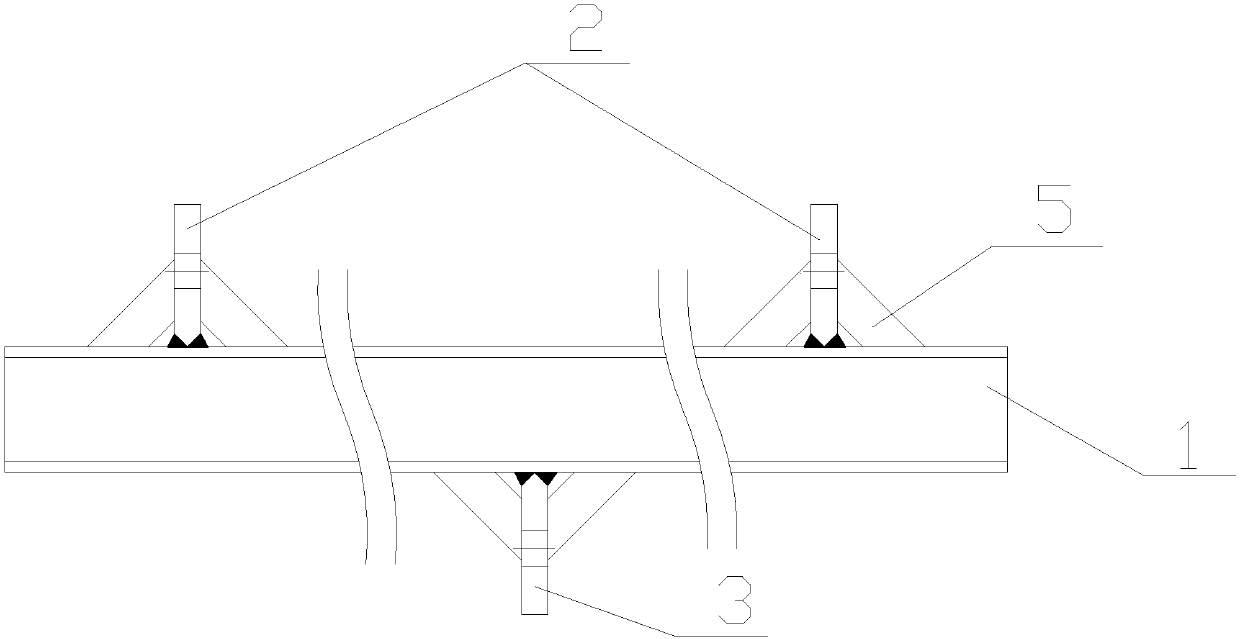

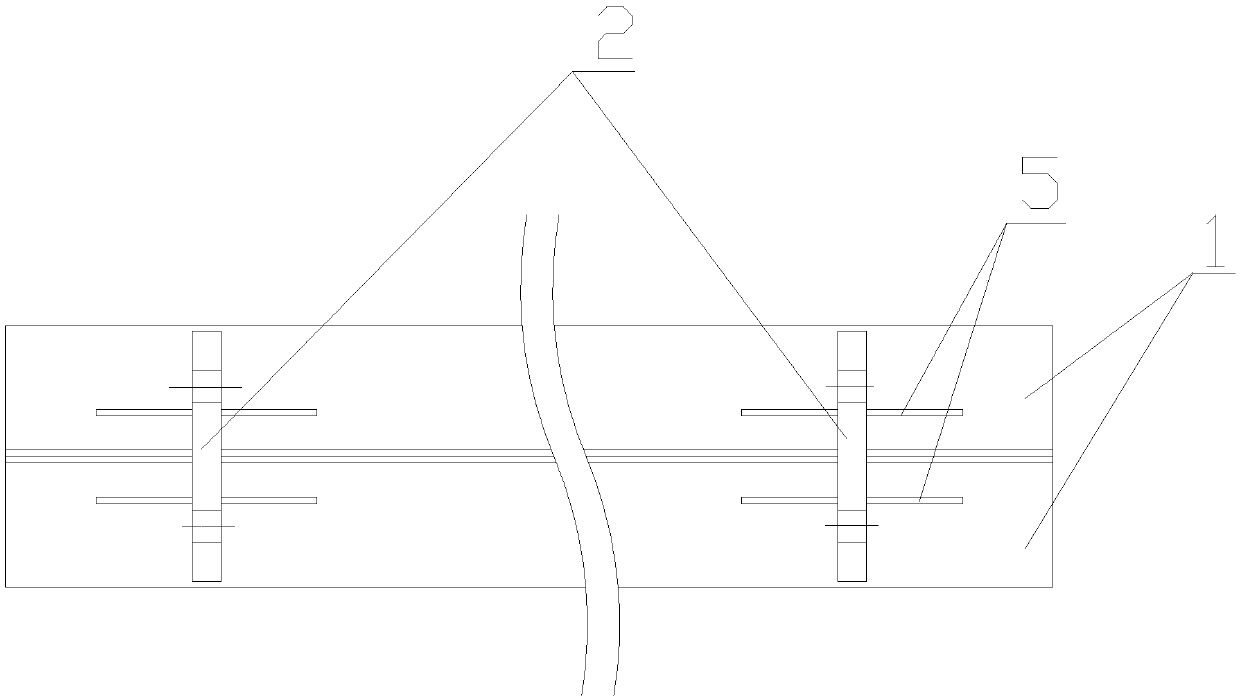

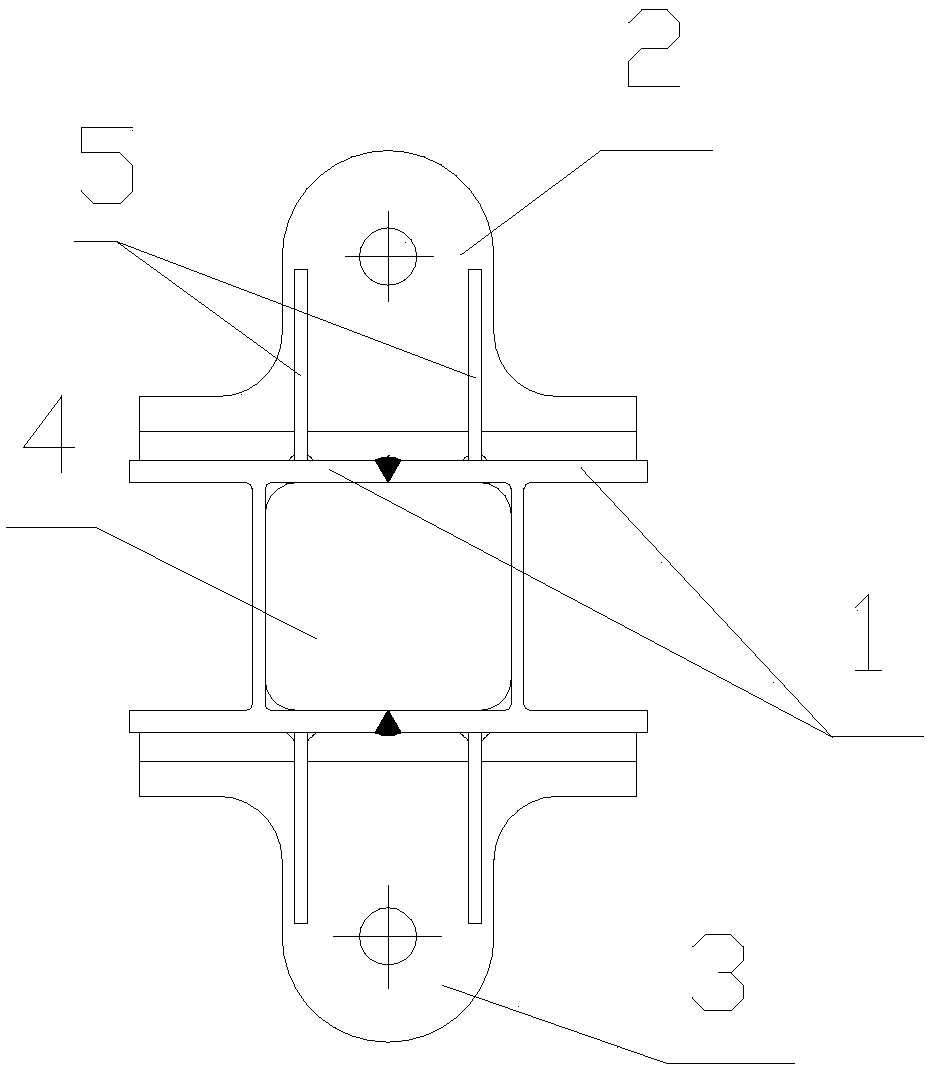

[0035] The present invention is a kind of tooling for hoisting and transporting large parts with double cranes, which includes a main beam formed by welding two side-by-side H-shaped steel 1 along the upper and lower flanges, and the side of the flange that is welded on each H-shaped steel 1 A number of lining plates 4 are welded on the "匚"-shaped part; two driving lugs 2 are welded symmetrically on the upper side of the main girder along the longitudinal centerline of the main girder, and a large lifting lug 3 is welded in the middle of the lower part; Both sides of the two driving lugs 2 and the large lifting lug 3 are respectively symmetrically welded with ribs 5, and the bottom of each rib 5 is welded and fixed to the upper surface of the flange of the H-shaped steel 1 of the main beam. The present invention uses H-shaped steel 1 as the material of the main girder, and fully utilizes its characteristics such as light weight, high strength, high stability, and ease of machin...

Embodiment 2

[0040] The present invention is a kind of method for making the tooling used in the above-mentioned embodiment for double-travel hoisting and transporting large pieces, comprising the following steps:

[0041] 1) Determine the length of the two H-shaped steels 1 constituting the main girder according to the safety distance when the two vehicles run parallel, and determine the height and width of the liner 4 according to the thickness and height of the flanges of the two H-shaped steels 1; at the same time, Prepare two driving lugs 2, large lifting lugs 3 and several ribs 5 with grooves on the bottom;

[0042] 2), remove oil stains and surface rust on the outer surfaces of the two flanges of the selected two H-shaped steels 1, and then correct the two H-shaped steels 1 and cut each H-shaped steel 1 by a semi-automatic flame cutting machine. One-sided V-shaped grooves are respectively made on the same side of the flange, and then straightened by flame and polished with an angle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com