Battery cell getting-into-shell separating and spacing device

A battery cell and separation technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of hidden dangers in stability, increase of unstable factors, uncontrollable free state, etc., and achieve simple and convenient separation process, mechanism streamlined effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

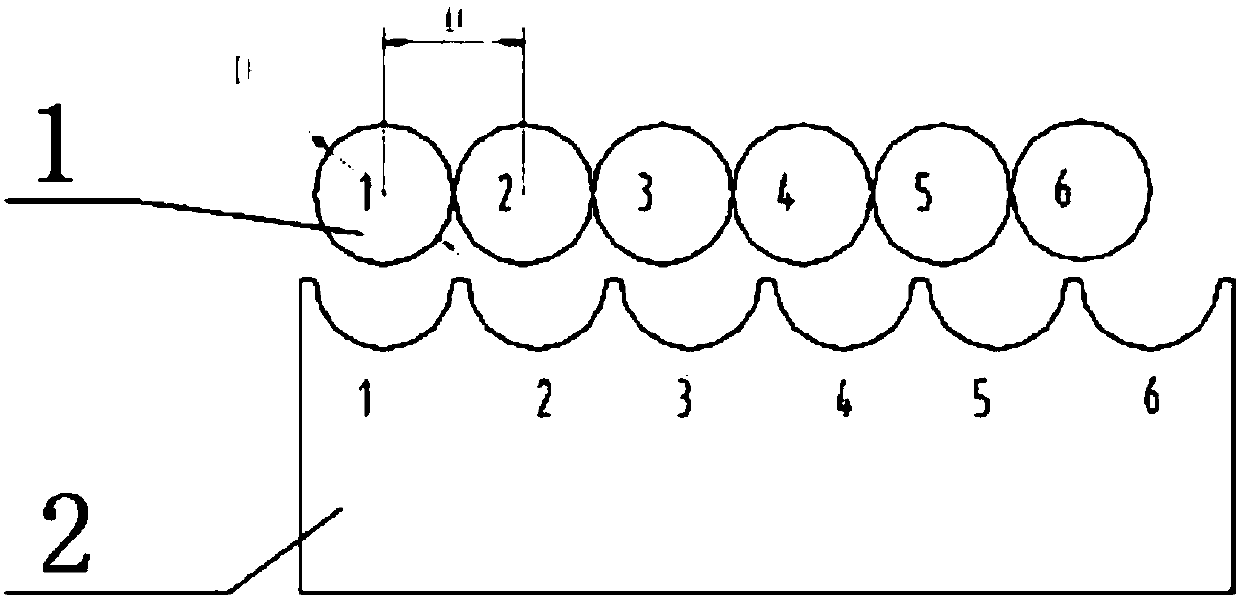

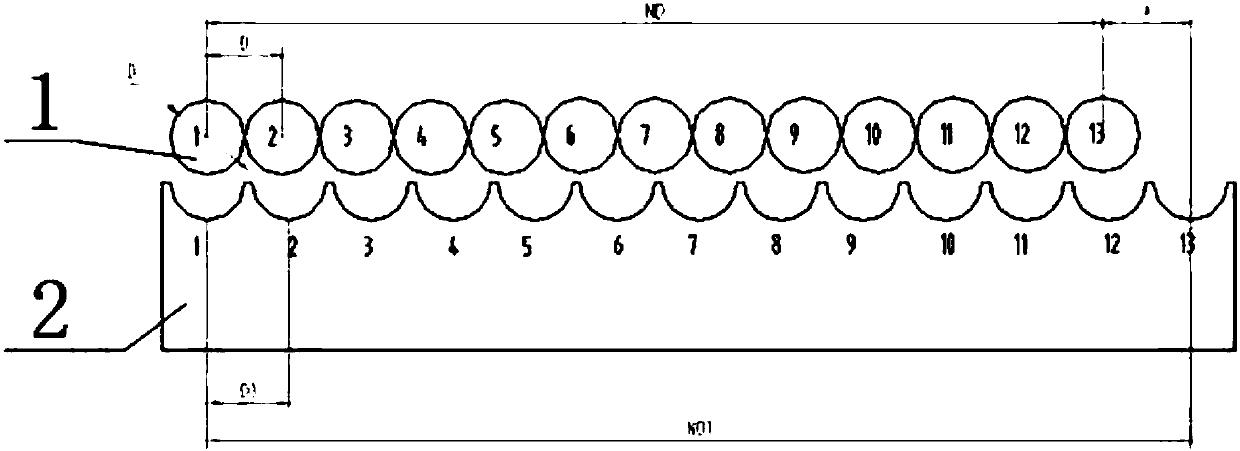

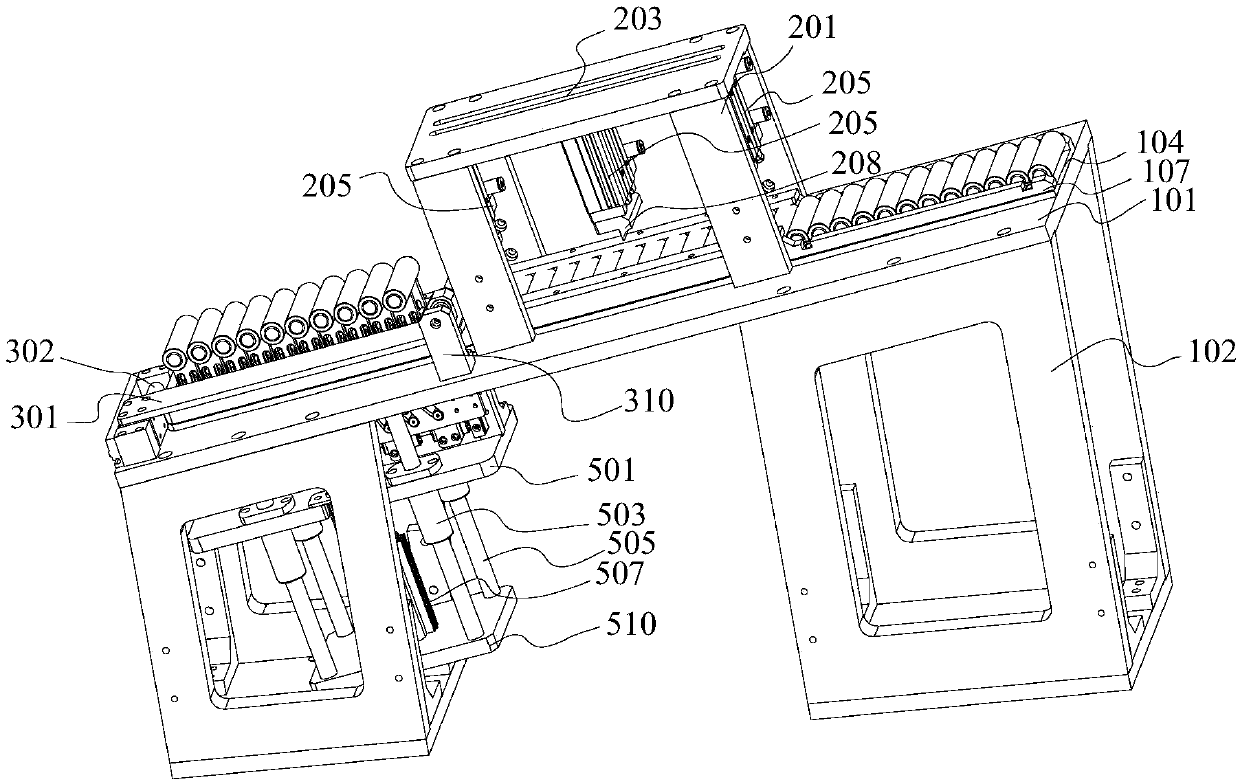

[0047] see image 3 As shown, the present invention provides a device for distributing and separating cells into the shell, including: a support frame body, a cell raceway 104 arranged on the support frame body, a material distribution mechanism, a material blocking mechanism, and a jacking and separation distance mechanism.

[0048] The support frame body includes an inclined slope 101 and support frames 102 respectively arranged at the bottom of the high end and the bottom of the low end of the slope 101 .

[0049] The cell raceway 104 is adapted to be assembled on the slope surface 101 of the supporting frame body, and a hollow groove 105 is provided on the part of the cell raceway 104 corresponding to the support frame 102 on the lower end surface.

[0050] Preferably, the battery raceway 104 is provided with a raceway baffle 107 adapted to change the width of the battery raceway 104 along one side edge of the battery raceway 104 in the length direction.

[0051]The mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com