Microminiature balance-force type sealed DC electromagnetic relay

A technology of electromagnetic relay and balancing force, applied in electromagnetic relay, detailed information of electromagnetic relay, relay, etc., can solve the problems such as difficult to remove the excess of yoke and armature, high requirements for precision assembly of parts, inconvenient adjustment and detection, etc. , to achieve the effect of mass production, easy assurance of assembly accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

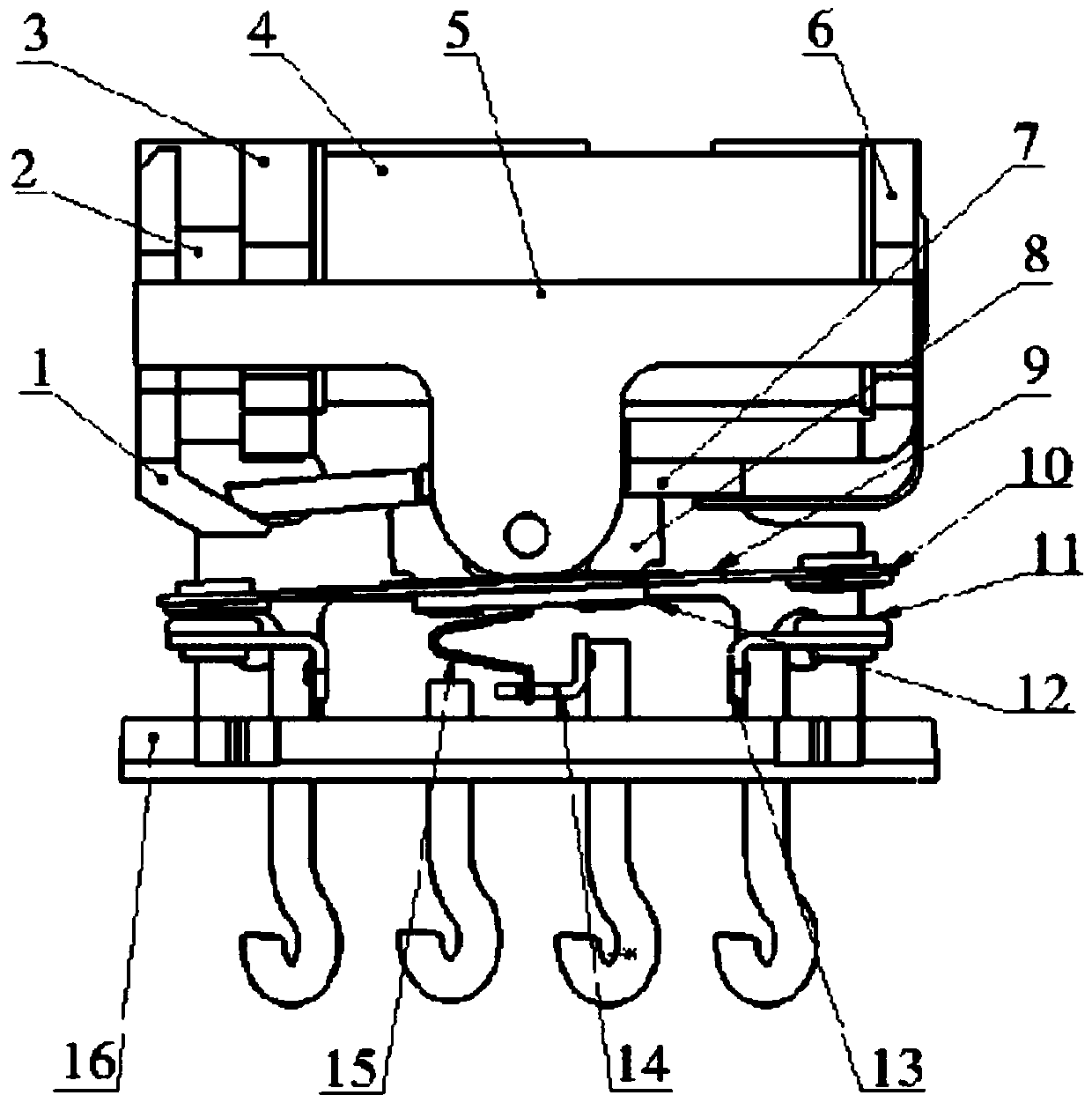

[0018] An ultra-small balanced force type sealed DC electromagnetic relay, which includes a first yoke 1, a magnetic steel 2, a second yoke 3, a coil 4, a shaft frame 5, a third yoke 6, an armature 7, and an insulating block 8 , moving reed 9, moving contact 10, static contact 11, pressure piece 12, transition piece 13, conductive piece 14, connection card 15 and base 16, described conductive piece 14 is fixedly installed on the base 16, and described The lower end of the connecting card 15 is installed in the mounting hole of the conductive sheet 14, the upper end of the connecting card 15 is installed on the bottom surface of the pressing sheet 12, and the moving reed 9 is installed in the mounting hole of the insulating block 8. The movable contact 10 is fixedly mounted on the right end of the movable reed 9, the transition piece 13 is mounted on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com