Pneumatic tire

A technology of pneumatic tires and tires, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., to improve wet performance and handling stability, improve rigidity, and prevent shear deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

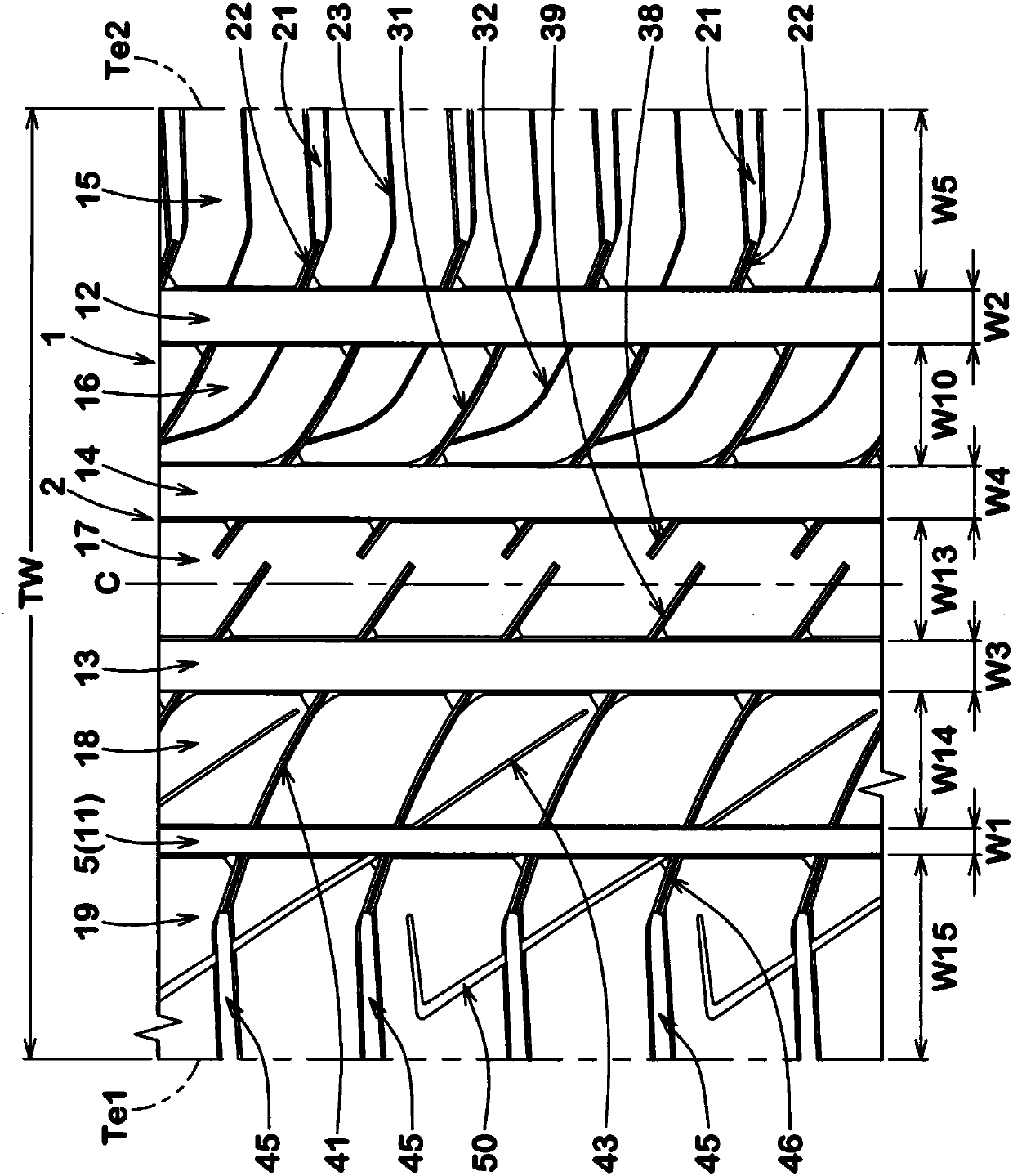

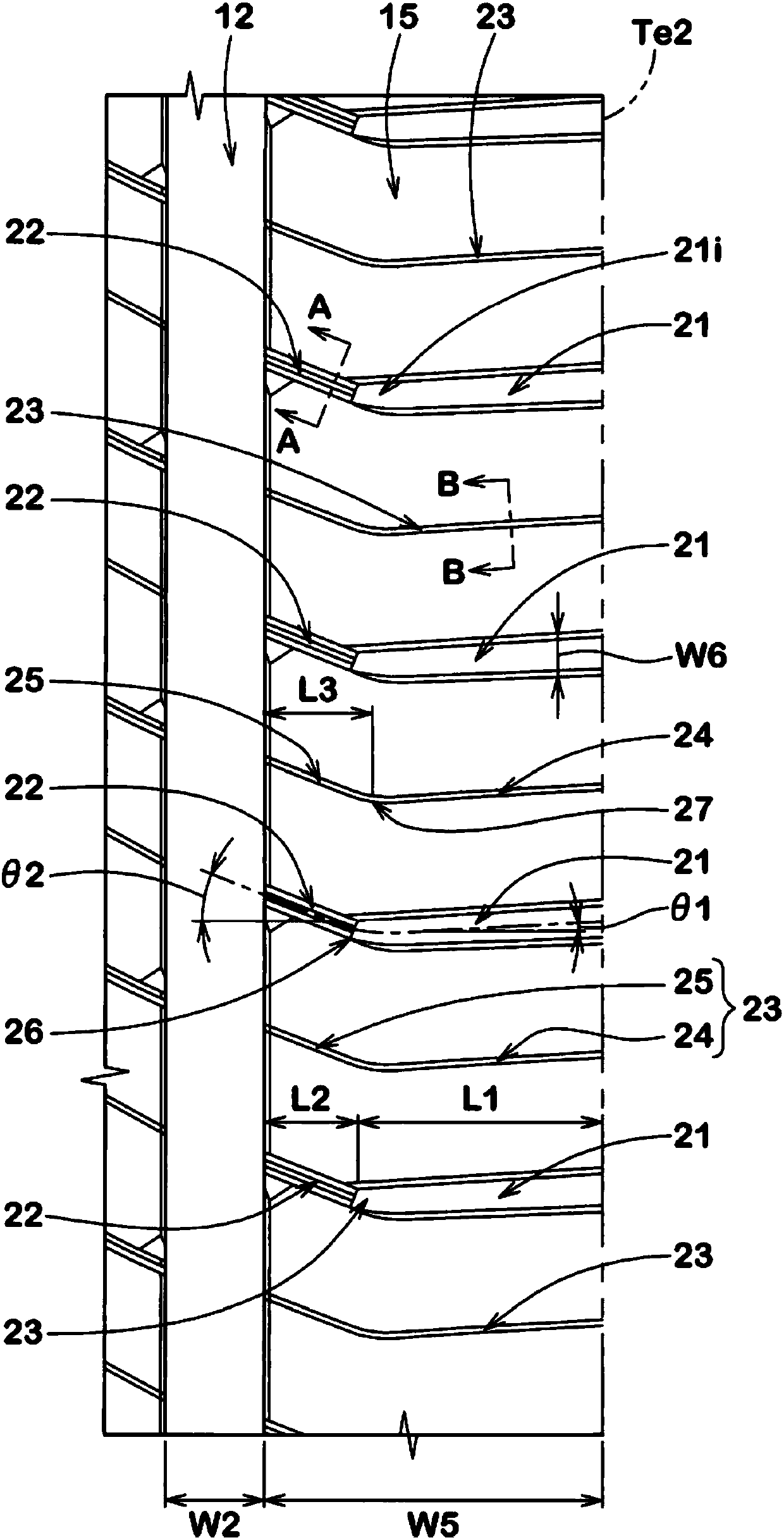

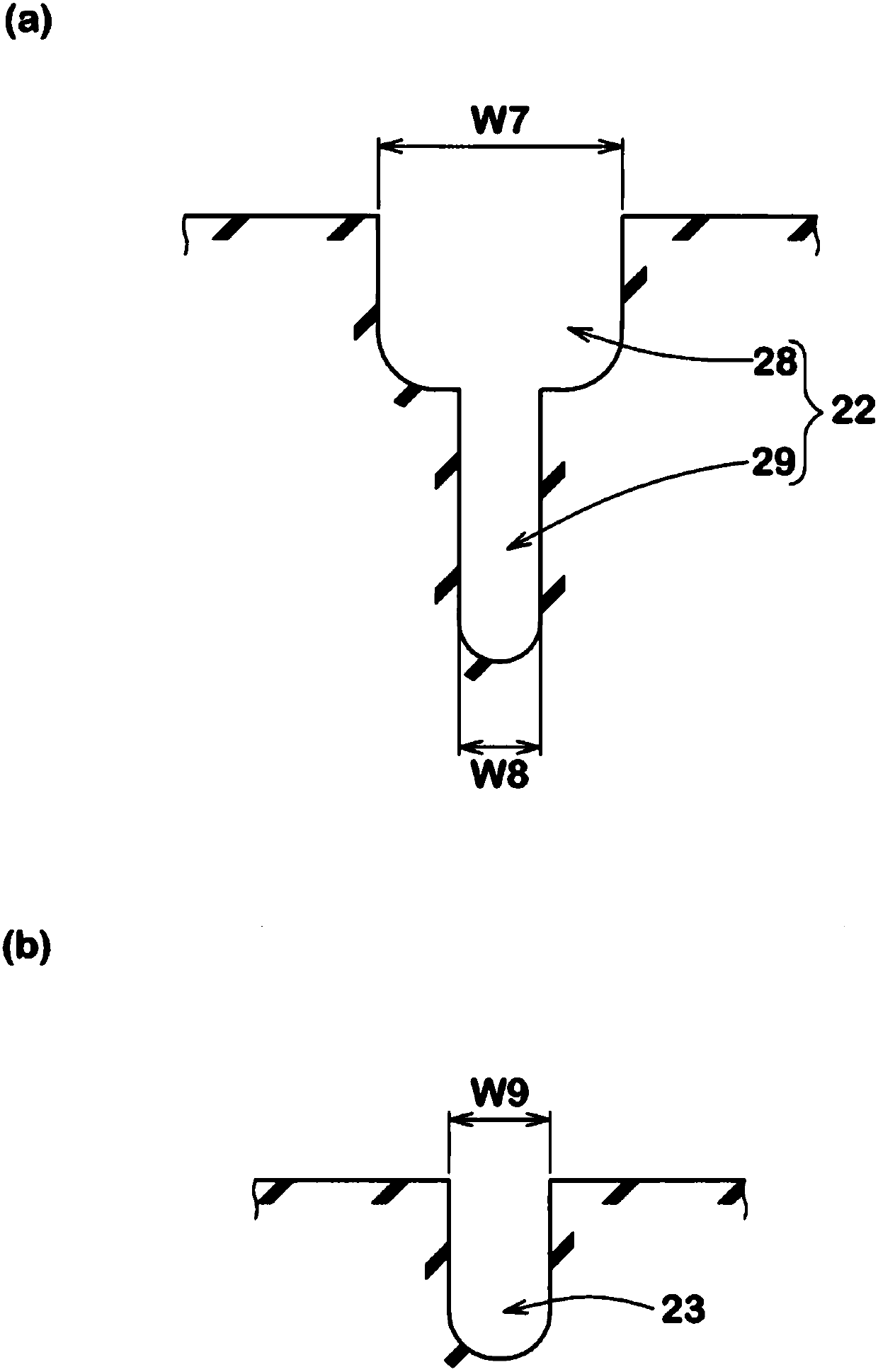

[0029] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. figure 1 It is a developed view showing a tread portion 2 of a pneumatic tire (hereinafter also simply referred to as a "tire") 1 according to an embodiment of the present invention. The tire 1 of the present embodiment is applicable to, for example, passenger vehicles.

[0030] Such as figure 1 As shown, the tread portion 2 has an asymmetrical tread pattern specifying an installation orientation on a vehicle. The tread portion 2 has a first tread end Te1 positioned outside the vehicle when the tire 1 is mounted on the vehicle, and a second tread end Te2 positioned inside the vehicle when mounted on the vehicle. For example, a character or a symbol is attached to a side wall portion (not shown) to indicate an installation orientation on a vehicle.

[0031] Each of the tread ends Te1 and Te2 is the outermost contact position in the tire axial direction when a normal l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com