Method for preventing hot rolled reel from being flattened

A technology of hot-rolled coils and flat coils, applied in metal rolling, metal rolling, manufacturing tools, etc., which can solve problems such as difficult industrial utilization, low production efficiency, and complicated operation, so as to reduce the phenomenon of flat coils and increase coiling The effect of pressure, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention provides a method for preventing flat coils of hot-rolled coils, comprising the following steps:

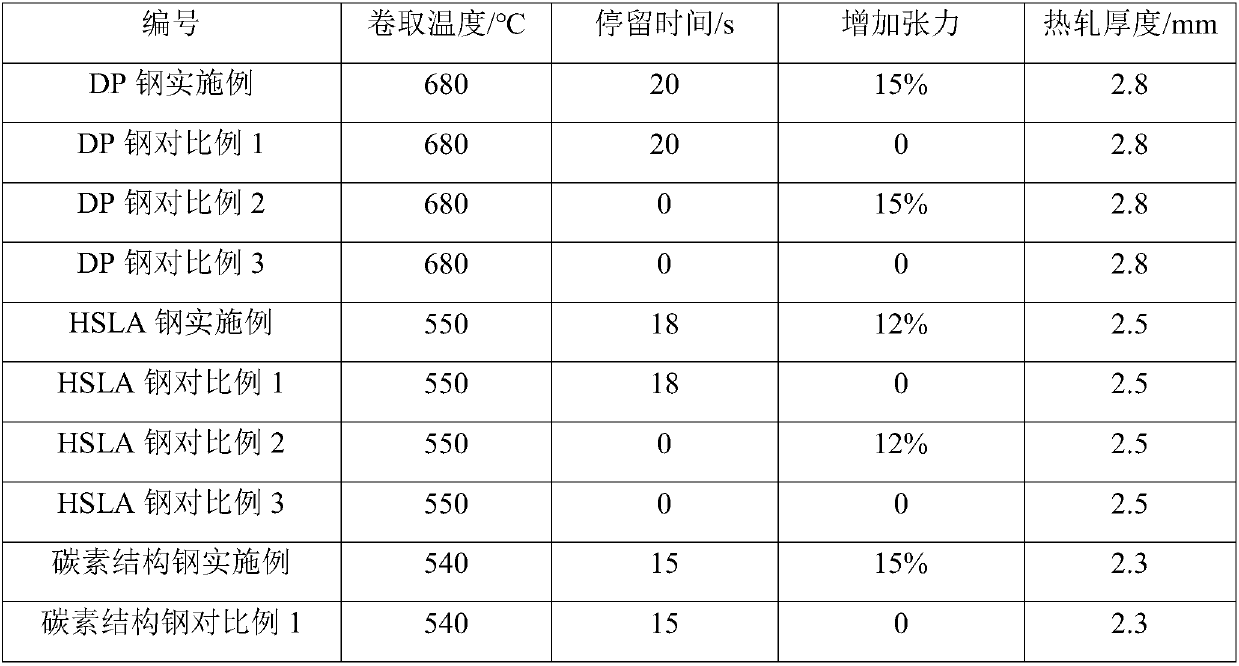

[0017] After the hot-rolled strip is cooled by laminar flow, it is rapidly cooled to 650-700°C or 500-550°C for coiling, and the hot-rolled steel coil after coiling stays on the coiler for 5-20s; the coiling tension is relatively high Regular crimp tension increased by 5-10%.

[0018] When the steel plate is crimped, the flat coil usually occurs within 30s after coiling. The present invention especially prolongs the time for the steel plate to be rolled on the reel, and stays for 5-20s after crimping, so that it can be effectively rolled on the reel. Under the action of support, the generation of flat roll can be suppressed. Directly prolonging the residence time, the operation is simple and convenient, and the effect of significantly reducing the flat roll rate can be achieved, and the cost reduction effect is obvious.

[0019] On the other hand, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com