Glass deep processing production line distributed integration method and system thereof

A technology of deep processing and integration of glass, applied in general control systems, control/regulation systems, instruments, etc., can solve the problem of poor real-time performance, inability to realize segmented integration and testing in different places, and the virtual operation process of the whole line cannot truly simulate the production process And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

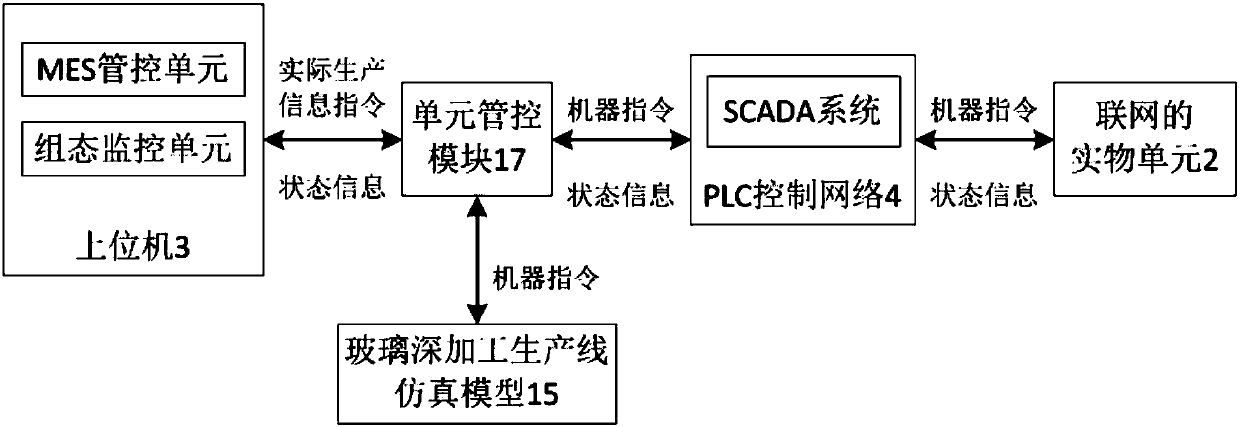

[0081] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0082] In the distributed integration method of the glass deep processing production line in this embodiment, the glass deep processing production line is split into four physical units 2, and the four physical units 2 are designed, manufactured and tested in different regions, and the four physical units 2 are It is the original film warehouse physical unit 21, the tempered warehouse physical unit 22, the tempered grate piece physical unit 23 and the hollow paired physical unit 24, such as figure 1 shown, including the following steps:

[0083] The three-dimensional modeling step is to carry out three-dimensional modeling to the four physical units 2 in the simulation system 1, including carrying out three-dimensional modeling to all stand-alone physical equipment 25 in each of the physical units 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com