High-consistency hydropulper

A pulper and water conservancy technology, applied in the field of papermaking machinery, can solve the problems of large power and difficult repair, and achieve the effects of small power, large inclination angle, large load capacity and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

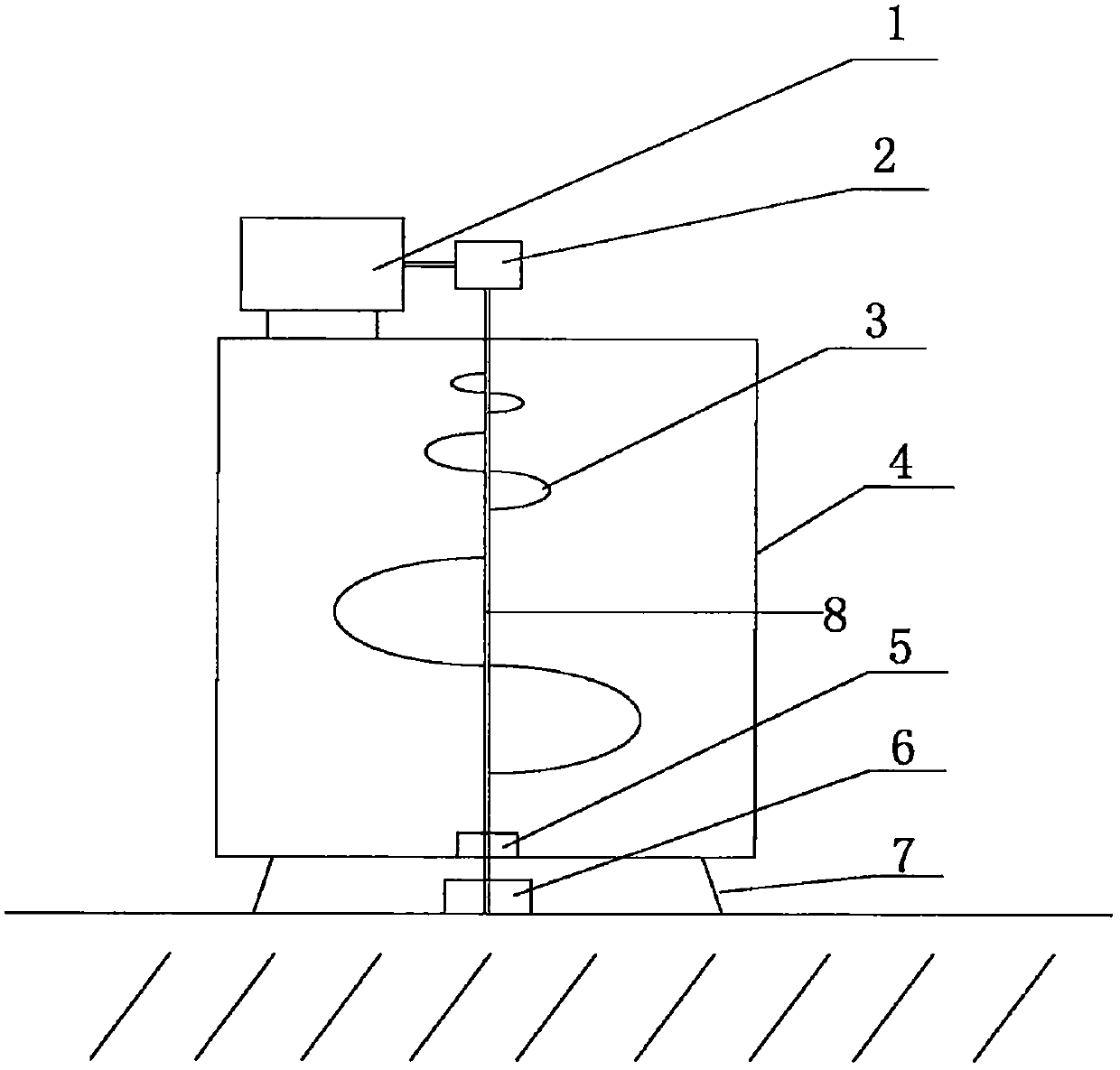

[0014] as attached figure 1 Shown: an improved high-concentration hydraulic pulper, including: a pulper tank 4, a motor 1, a transmission device 2, a transmission shaft 8, blades 3, an anti-deflection sealing device 5 and a joint bearing 6, wherein the The motor 1 and the transmission device 2 are located at the top of the outside of the pulper tank 4, the pulper tank 4 is a cylindrical tank, and the blade 3 is spirally mounted on the transmission shaft 8, The diameter of the blades 3 gradually increases from top to bottom, and every two blades 3 form a group, and a gap is provided between each group to reduce resistance. The gap is 10-50 cm, and the anti-deflection The sealing device 5 is located at the bottom inside the pulper tank 4 , and the joint bearing 6 is located at the bottom outside the pulper tank 4 .

Embodiment 2

[0016] On the basis of embodiment 1, the preferred embodiment of the present invention is, described blade 3, further be the blade 3 of ellipse, the quantity of blade 3 is 2 groups, and the distance between each group is 40cm, all the other structure and implementation Example 1 is exactly the same.

Embodiment 3

[0018] On the basis of embodiment 1, the preferred embodiment of the present invention is, described blade 3, further be the blade 3 of ellipse, the quantity of blade 3 is 3 groups, and the distance between each group is 30cm, all the other structure and implementation Example 1 is exactly the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com