Synchronous correcting assembly for symmetry properties of cassette die-cutting machine

A symmetrical, die-cutting machine technology, applied in metal processing, measuring devices, instruments, etc., can solve problems such as waste of resources and lack of timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

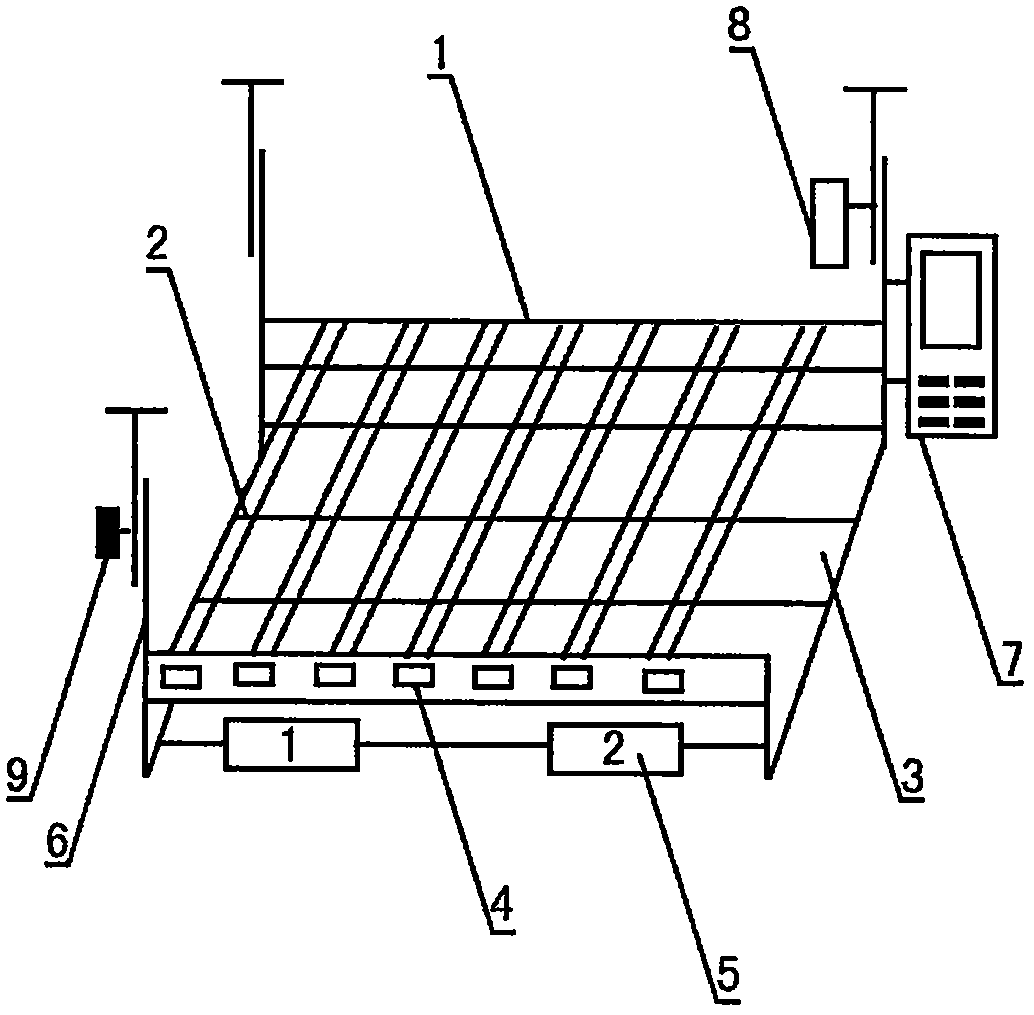

[0012] Example: as shown in the attached drawings. A symmetrical synchronous proofing assembly for a cassette die-cutting machine, comprising a frame body (1), wherein the frame body (1) is designed with a double plate surface and includes a horizontal and vertical indentation sensing device (2), a picture positioning device (3), and a side The distance measuring device (4) is arranged on the side, and the infrared emission device (5) is located under the frame body (1). ) is remotely connected to the computer, and the infrared horizontal and vertical line position structure is set according to the layout of the card box, and the sensing data is analyzed by the central control device (8) to judge its symmetry and give corresponding prompts.

[0013] A symmetry synchronization proofing component of a cassette die-cutting machine is provided with a warning device (9), and a corresponding prompt is issued according to a corresponding code when the detection data judges that the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com