Manual three-station rewinder system and application method and application thereof

A three-station, rewinding machine technology, applied in the field of rewinding machines, can solve problems such as poor compounding effect, unfavorable market competitiveness of enterprises, and high labor costs, so as to achieve easy operation, save time for changing stations, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

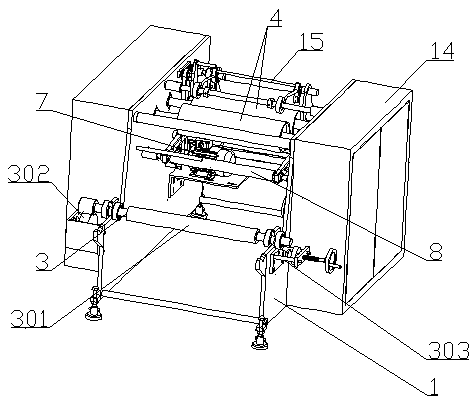

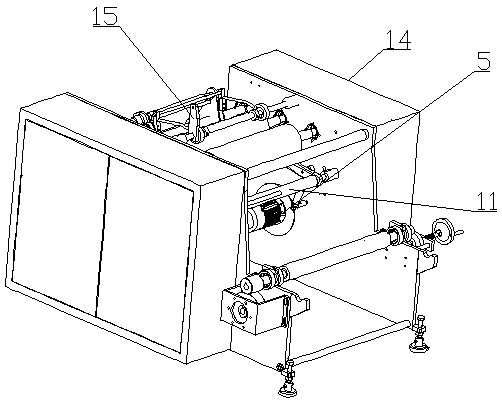

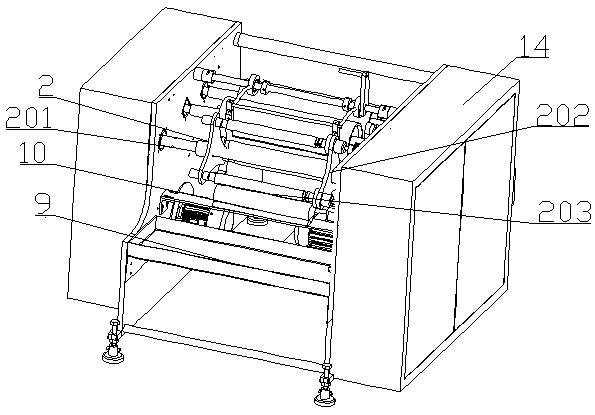

[0065] As shown in the figure: a manual three-station rewinding machine, which includes two opposite wall panels 1 and a rewinding mechanism arranged between the two wall panels 1, the rewinding mechanism includes a three-station work Mechanism 2, the three-station working mechanism 2 includes a three-station fixed shaft 201 with two ends installed on the wallboard 1 and two three-station work disks 202 fixed at both ends of the three-station fixed shaft 201, the three-station There are three fixed holes evenly distributed on the work disk 202 of the station, and the two opposite fixed holes on the two three-station work disks 202 are connected by the three-station rotating shaft 203. A three-station synchronous wheel 204, one end of the three-station rotating shaft 203 is fixedly connected to the three-station synchronous wheel 204, and any two adjacent three-station synchronous wheels 204 are connected through a transmission chain. The three-station synchronous wheel 204 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap