Tire reflective stripe laminating machine

A technology of reflective strips and laminating machines, applied in the directions of labeling machines, labels, packaging, etc., can solve the problems of uneven lamination, slow manual lamination of reflective strips, and low sticking quality, so as to avoid cassettes and repeated sticking. , Improve the effect of bonding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

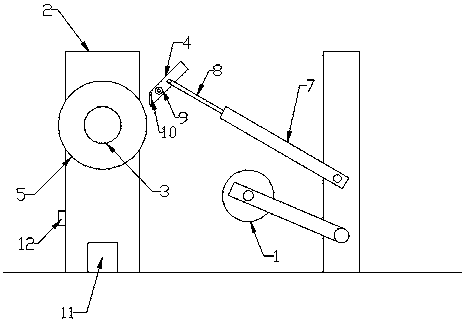

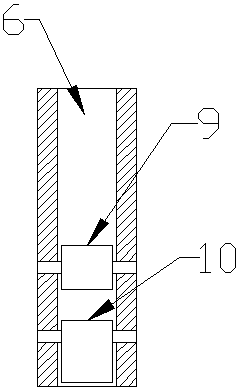

[0020] As the best embodiment of the present invention, this embodiment discloses a tire reflective strip laminating machine, such as figure 1 As shown, it includes a feeding wheel 1 and a frame 2, which is characterized in that: the frame 2 is provided with a rotating shaft 3 and a guide 4, the rotating shaft 3 is connected with the motor 11, and the rotating shaft 3 is provided with a mounting drum 5, installed The drum 5 is consistent with the inner diameter of the tire to be bonded; the guide 4 is provided with a through groove 6 consistent with the width of the reflective tape; the guide 4 is located obliquely above the installation drum 5, and the feed end of the through groove 6 is facing The charging groove of the feeding wheel 1, the through groove 6 coincides with the symmetrical axis of the feeding groove of the feeding wheel 1, so as to ensure that the reflective tape will not be dislocated during the transmission process, causing the reflective tape to be twisted o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com